2.5.2 Operation as a

Voltage

Controlled Generator

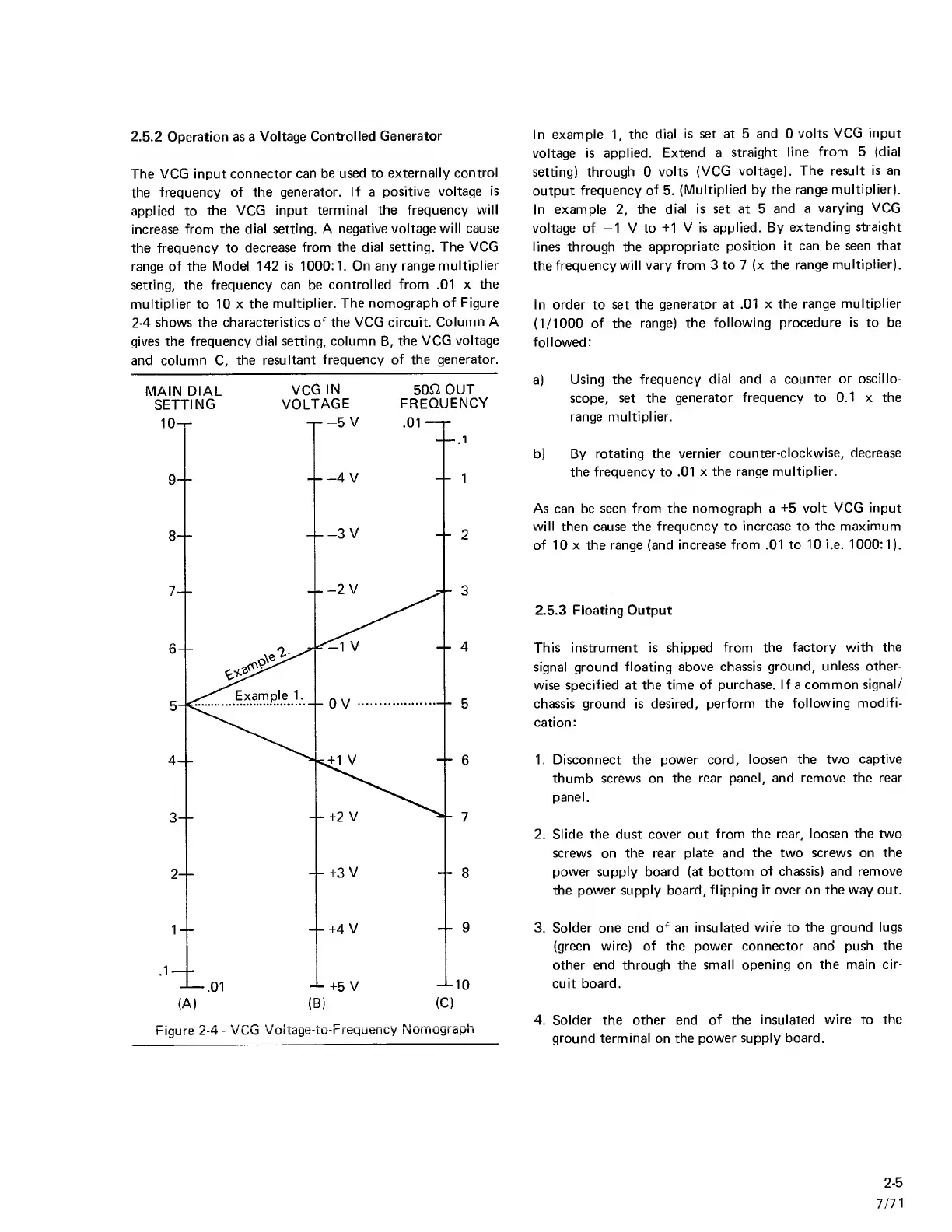

The VCG input

connector can

be used to externally

control

the

frequency of the

generator. If

a

positive voltage

is

applied to

the

VCG

input

terminal the frequency

will

increase

from the dial setting. A

negative

voltage

will cause

the

frequency to

decrease from

the dial setting. The VCG

range

of the Model 142 is

1000:1. On

any

range

multiplier

setting, the frequency

can be

controlled from .01

x the

multiplier to 10 x

the

multiplier. The nomograph

of Figure

2-4

shows the characteristics

of the VCG circuit.

Column A

gives the frequency

dial setting, column

B,

the

VCG

voltage

and

column

C,

the resultant

frequency of the generator.

MAIN

DIAL

VCG

IN

50fi

OUT

SETTING

VOLTAGE

FREQUENCY

In example

1,

the dial

is set at 5

and

0

volts VCG input

voltage

is applied.

Extend

a

straight

line from

5

(dial

setting)

through

0

volts (VCG

voltage).

The result is an

output

frequency of

5.

(Multiplied by

the range

multiplier).

In example

2,

the dial is set

at

5

and a

varying VCG

voltage of

-1

V to -M

V is applied. By

extending straight

lines through

the

appropriate

position it can be

seen that

the

frequency will vary

from 3 to

7

(x the

range

multiplier).

In order to set

the generator at .01

x the

range multiplier

(1/1000

of the range)

the

following procedure is to be

followed:

a)

Using the

frequency

dial and

a

counter

or oscillo-

scope,

set the

generator frequency to 0.1 x the

range multiplier.

b) By

rotating the vernier

counter-clockwise, decrease

the frequency to .01

x the range

multiplier.

As

can be seen from the

nomograph

a

-i-5

volt VCG input

will then

cause

the frequency to increase to

the maximum

of 10 X the range (and

increase from .01 to

10 i.e.

1000:1).

2.5.3 Floating Output

This instrument is shipped

from the factory

with the

signal ground

floating above chassis

ground,

unless other-

wise specified at

the time of purchase. If a common

signal/

chassis ground is desired,

perform the

following modifi-

cation:

1. Disconnect the

power

cord,

loosen

the two captive

thumb screws on

the rear panel, and

remove the rear

panel.

2. Slide the dust

cover

out

from

the

rear,

loosen the two

screws on

the

rear

plate and the two screws on

the

power supply board (at bottom

of chassis) and remove

the

power supply board, flipping

it over

on

the way out.

3. Solder one end

of

an

insulated wire to

the ground lugs

(green wire) of the power connector

and push the

other end through the

small opening on the main

cir-

cuit

board.

4. Solder the other end

of

the

insulated wire to

the

ground

terminal

on

the power supply board.

2-5

7/71

Loading...

Loading...