concise and

are

written for

the experienced electronics

technician or

field engineer having a working

knowledge

of this type of

instrumentation.

WAVETEK

maintains

a

factory repair department

for

those

customers not

possessing the necessary test equipment or

personnel

to

maintain this type of

instrument. If an

instru-

ment is returned to

the factory for calibration

or

repair,

a

detailed

description

of the specific problem should

be

attached. This will hasten turnaround time.

4.2.1

Recommended Test Equipment

The following

test

equipment

(or

equivalent)

is recom-

mended for this calibration procedure. A quick checkout

of the instrument can

be made by comparing the indicated

parameters with those given in the specifications

portion of

Section 1.

NOTE

The entire calibration procedure

must be read

first

to determine initial control settings and

test equipment

connections required before

attempting recaiibration. The

steps

of this

pro-

cedure should be performed in the sequence

given,

and the parts within

each step should

also be performed

in the sequence given.

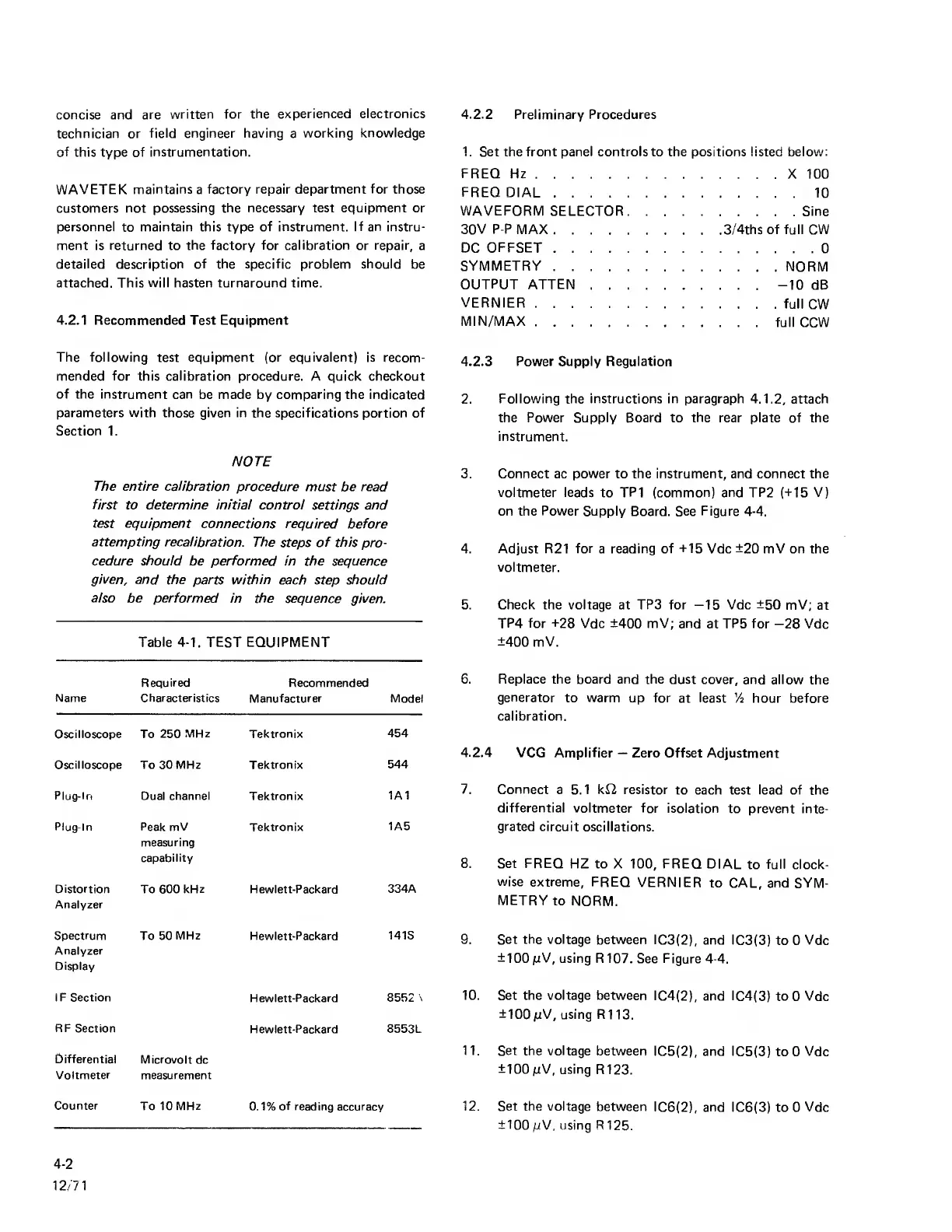

Table

4-1.

TEST

EQUIPMENT

Required Recommended

Name Characteristics

Manufacturer Model

Oscilloscope To

250

MHz

Tektronix

454

Oscilloscope To 30 MHz Tektronix

544

Plug-In

Dual

channel

Tektronix

1A1

Plug-In Peak mV

measuring

capability

Tektronix

1A5

Distortion

Analyzer

To 600

kHz

Hewlett-Packard

334A

Spectrum

Analyzer

Display

To 50

MHz

Hewlett-Packard

141S

IF Section

Hewlett-Packard

8552

\

RF

Section

Hewlett-Packard

8553L

Differential

Microvolt

dc

Voltmeter measurement

Counter

To 10

MHz

0.1%

of

reading accuracy

4.2.2

Preliminary Procedures

1.

Set the front panel controls to the positions listed below:

FREQ

Hz

X 100

FREQ

DIAL

10

WAVEFQRM

SELECTQR Sine

30V P-P MAX

3/4ths of full CW

DC

QFFSET

0

SYMMETRY

NQRM

OUTPUT ATTEN

-10

dB

VERNIER

full

CW

MIN/MAX

full CCW

4.2.3 Power Supply Regulation

2.

Following the instructions in paragraph

4.1.2,

attach

the Power Supply Board to

the

rear plate of the

instrument.

3. Connect ac power to the instrument, and connect the

voltmeter leads

to

TP1 (common) and TP2

(-M5

V)

on the

Power

Supply

Board. See

Figure

4-4.

4. Adjust R21 for a reading of

-t15

Vdc

±20

mV on the

voltmeter.

5. Check the voltage at TPS for

—15

Vdc ±50 mV;

at

TP4

for ±28

Vdc ±400 mV; and

at

TP5 for

—28

Vdc

±400 mV.

6. Replace the board and the

dust

cover,

and allow

the

generator

to warm up for

at

least

Vi hour before

calibration.

4.2.4

VCG Amplifier

—

Zero Offset Adjustment

7. Connect

a 5.1 ki2 resistor

to each test lead of the

differential voltmeter

for isolation

to prevent inte-

grated

circuit

oscillations.

8. Set FREQ

HZ to X

100,

FREQ

DIAL

to

full

clock-

wise extreme,

FREQ

VERNIER

to CAL, and

SYM-

METRY

to

NORM.

9.

Set the voltage

between IC3(2),

and IC3(3)

to 0

Vdc

±100

pV,

using R107.

See Figure

4-4.

10. Set the voltage between

IC4(2),

and IC4(3) to

0

Vdc

±100

/xV, using R1

13.

11. Set

the

voltage

between

IC5(2), and IC5(3)

to 0

Vdc

±100

mV,

using

R123.

12. Set the voltage

between

IC6(2), and

IC6(3) to 0 Vdc

±100

mV,

using R

125.

4-2

12/71

Loading...

Loading...