Top

section

Int.

section

track

Tighten

5/16”-18

Hex nut

Top

fixture

slide

Top

section

(1)1/4”-20

Track bolt and

(1) 1/4”-20

flange hex nut

Strut

13A

13B

13C

13D

track

Track

roller

13A

13C

Top fixture

slide

Tighten the

5/16”-18

Hex nut

To

Top section

Intermediate

section

13B

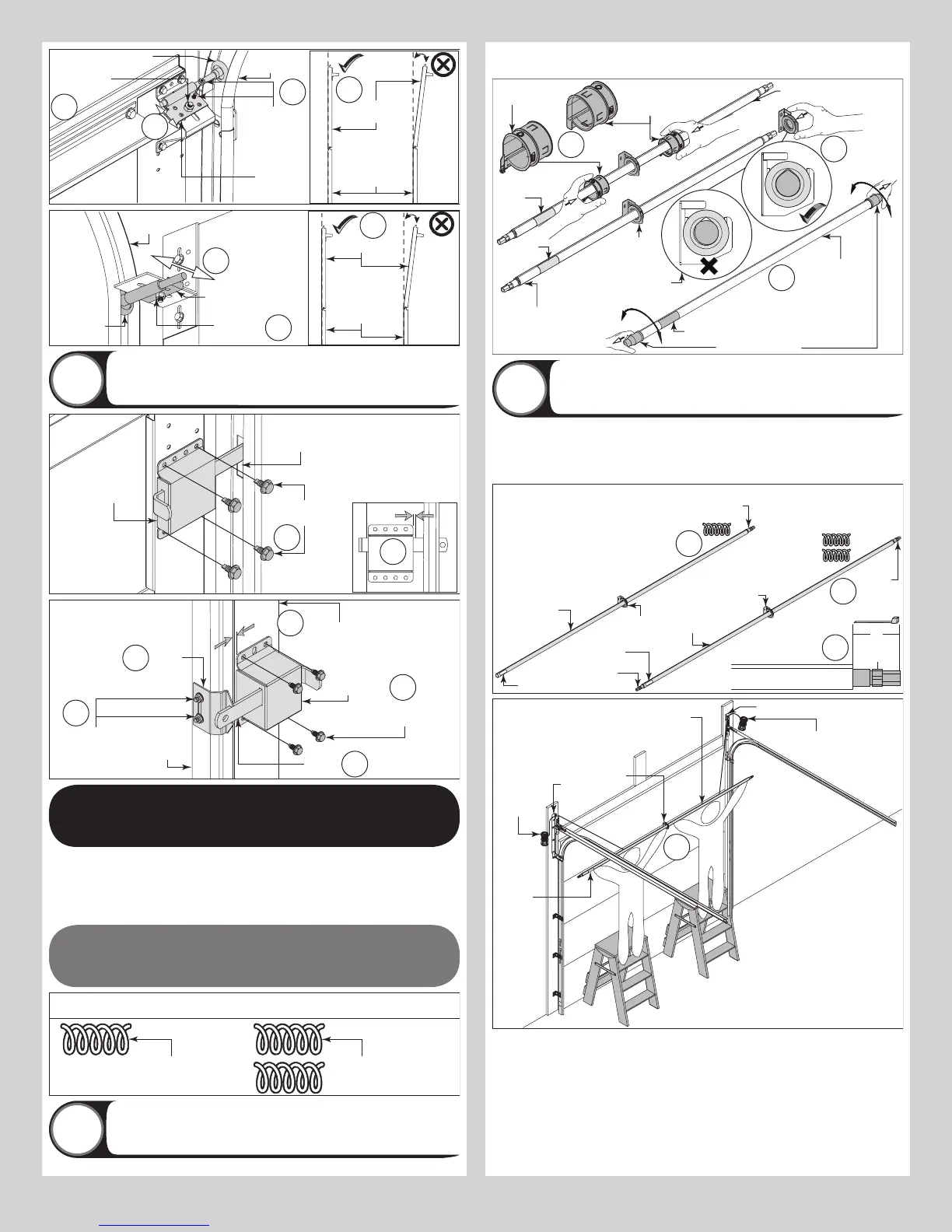

Attaching Inside Lock

Tools Required: Power drill, 7/16” Socket driver, Tape measure, Safety glasses,

Leather gloves

14

14A

Inside lock

End cap

1/4”-20 x 11/16”

Self drilling screws

Square hole in

vertical track

Lock

(Second)

section

14B

1/8”

9100 / 9405 /

9600 / 5120 /

5145 / 9800 only.

Second section

1/8”

Inside

lock

End cap

(4) 1/4”-20 x 11/16”

Self drilling screws

Striker

plate

Vertical

track

(2) 1/4” - 20 x

9/16” Track bolts

and (2) 1/4” - 20

Flanged hex Nuts

Inside

lock bar

14A

14B

14E

14D

14C

9700 anbd 9510 only.

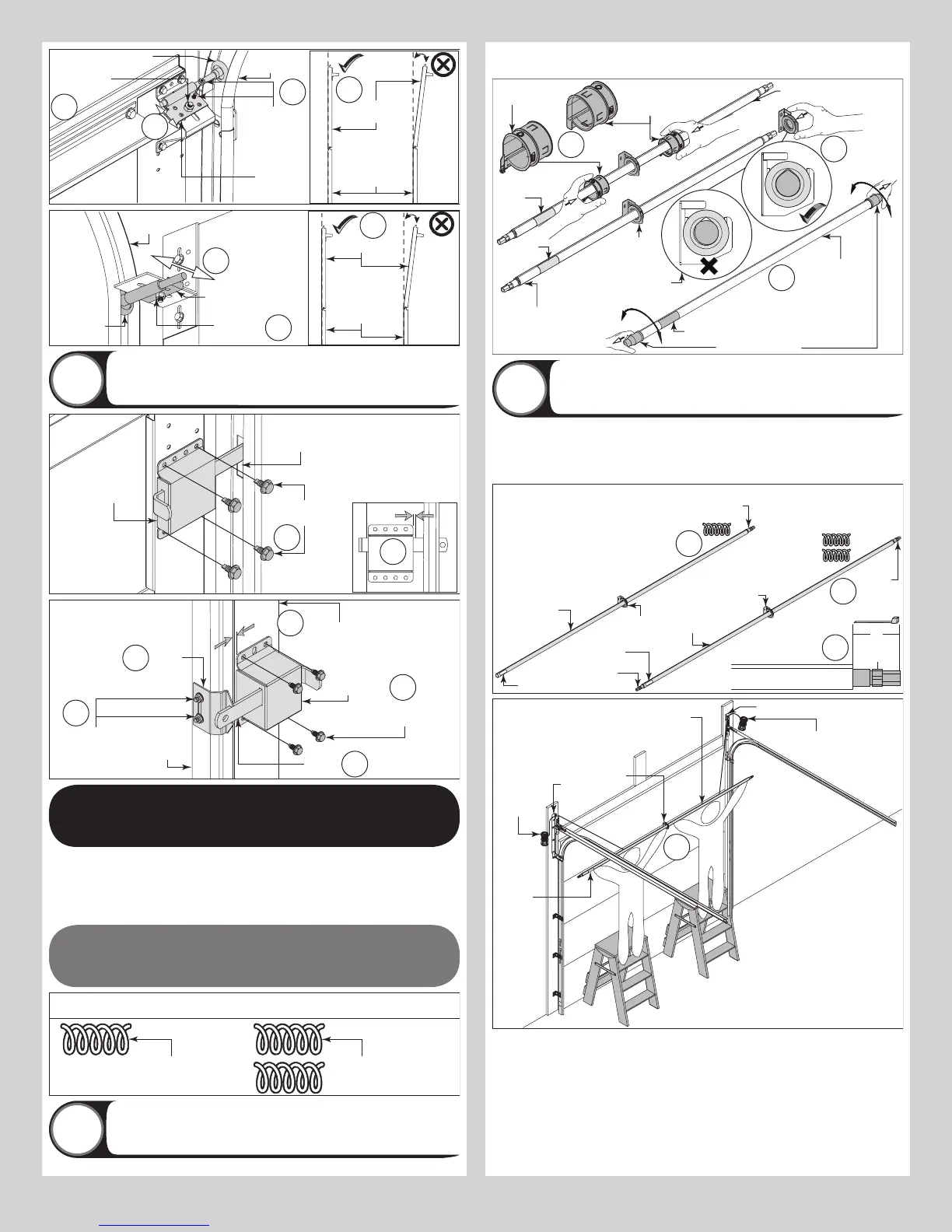

COUNTERBALANCE

INSTALLATION INSTRUCTIONS

NOTE: Refer to parts breakdown, to determine what type of counterbalance you have.

NOTE: If your door has TorqueMaster

®

Springs, proceed to Step A1.

NOTE: If your door has Torsion Springs, proceed to Step B1.

NOTE: If your door has Extension Springs, proceed to Step C1.

TORQUEMASTER

®

SPRING

Single Spring

Applications

Double Spring

Applications

NOTE: Some graphics in “A” are designated as either single spring applications or double

spring applications.

Preparing The TorqueMaster

®

Spring Tube

Assembly

Tools Required: Safety glasses, Leather gloves

A1

NOTE: TorqueMaster

®

springs come lubricated and pre-assembled inside the TorqueMaster

®

spring tube.

TorqueMaster

®

spring

tube

Remove shipping

Label

A1a

Left hand drum

wrap (Optional)

Right hand

drum wrap

(Optional)

A1b

A1c

Label

Label

TorqueMaster

®

spring tube

TorqueMaster

®

spring tube

Center

bracket

NOTE: Orient profile of

spring tube and center

bracket hole for smooth fit.

Installing Cable Drum Assemblies

Tools Required: Tape measure, Step ladder, Safety glasses, Leather gloves

A2

NOTE: Cable drum assemblies are marked right and left hand. Cable drums and TorqueMas-

ter

®

spring tube assembly are cam shaped to fit together only one way.

NOTE: Temporarily support the center of the TorqueMaster

®

spring tube assembly until the

center bracket is installed in step A4.

5”

Center

bracket

Winding

shaft

Winding

shaft

Winding

shaft

Winding

shaft

TorqueMaster

®

spring tube

Center

bracket

Label

Label

TorqueMaster

®

spring tube

A2a

A2a

A2b

TorqueMaster

®

spring tube

NOTE: For single spring applications,

there will be no left hand spring in the

TorqueMaster

®

spring tube assembly.

NOTE: If winding shaft is not visible out

of the right hand side, gently shake the

TorqueMaster

®

spring tube until

winding shaft sticks out 5”.

NOTE: If both winding shafts are

not visible, gently shake the

TorqueMaster

®

spring tube until

both winding shaft sticks out 5”.

Left hand

cable

drum

assembly

Right hand cable

drum assembly

NOTE: Working with a partner as needed, lift

the TorqueMaster

®

spring tube assembly up

and rest it on top of the flag angles.

Flag

angle

Center

bracket

Label

A2c

FOR SINGLE SPRING APPLICATIONS:

IMPORTANT: ENSURE THE SNAPS ON THE IDLER BRACKET (LEFT HAND SIDE) ARE EN-

GAGED INTO THE LEFT HAND CABLE DRUM, SO THAT IT DOES NOT COME BACK OUT.

NOTE: The idler bracket is designed for permanent assembly. Do not attempt to remove idler

bracket once inserted into the cable drum.

NOTE: The idler bracket must extend past the cable drum far enough to expose the groove.

Align the idler bracket groove with the round notch in the flag angle.

10

Loading...

Loading...