20

Please Do Not Return This Product To The Store. Contact your local Wayne-Dalton dealer. To find your local Wayne-Dalton dealer, refer to your

local yellow pages/business listings or go to the Find a Dealer section online at www.wayne-dalton.com

Tools Needed:

Tools Needed:

1-11/16” TO 1-3/4”

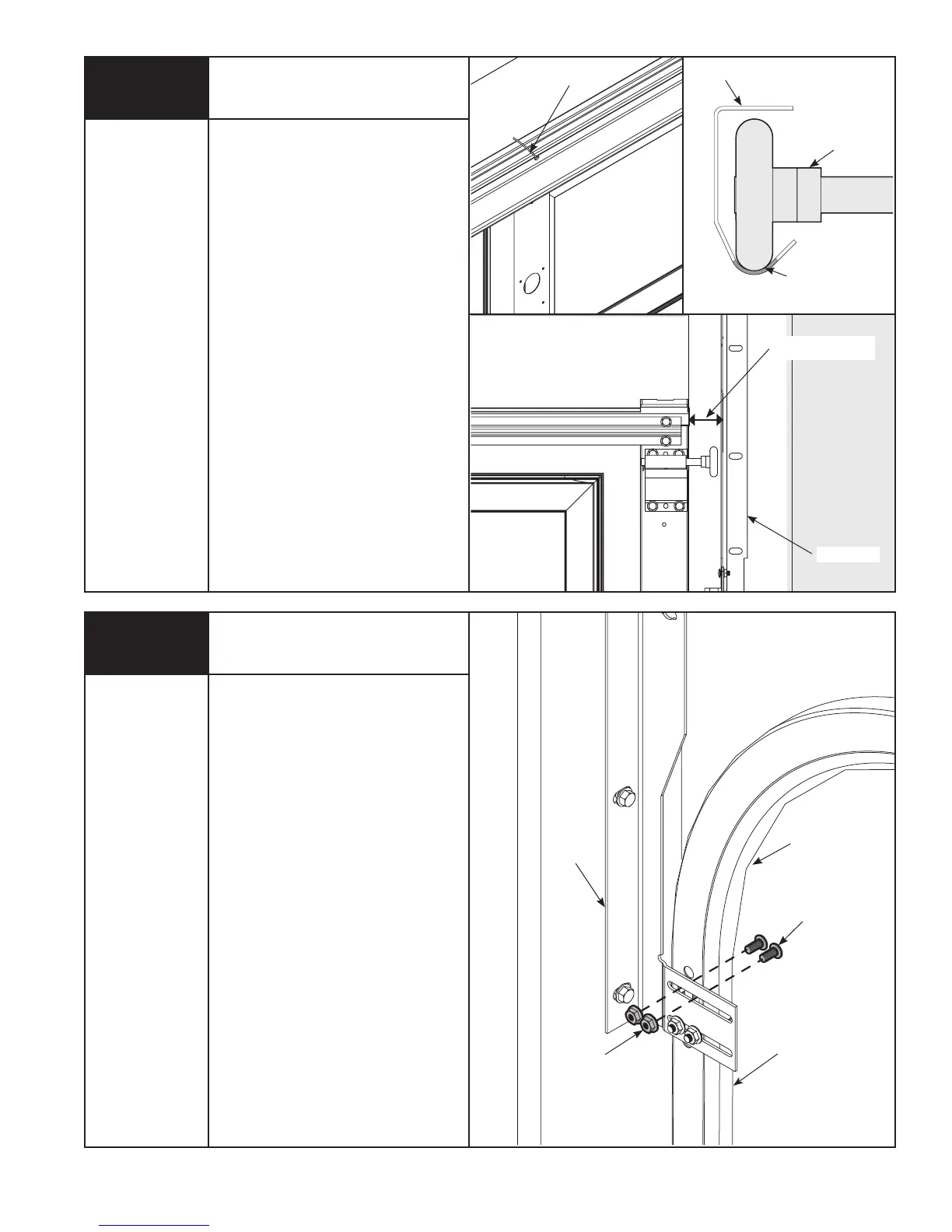

FLAGANGLE

TOP

SECTION

NAIL

ROLLER

VERTICAL TRACK

ROLLER AGAINST

VERTICAL TRACK

TOP SECTION

FLAGANGLE

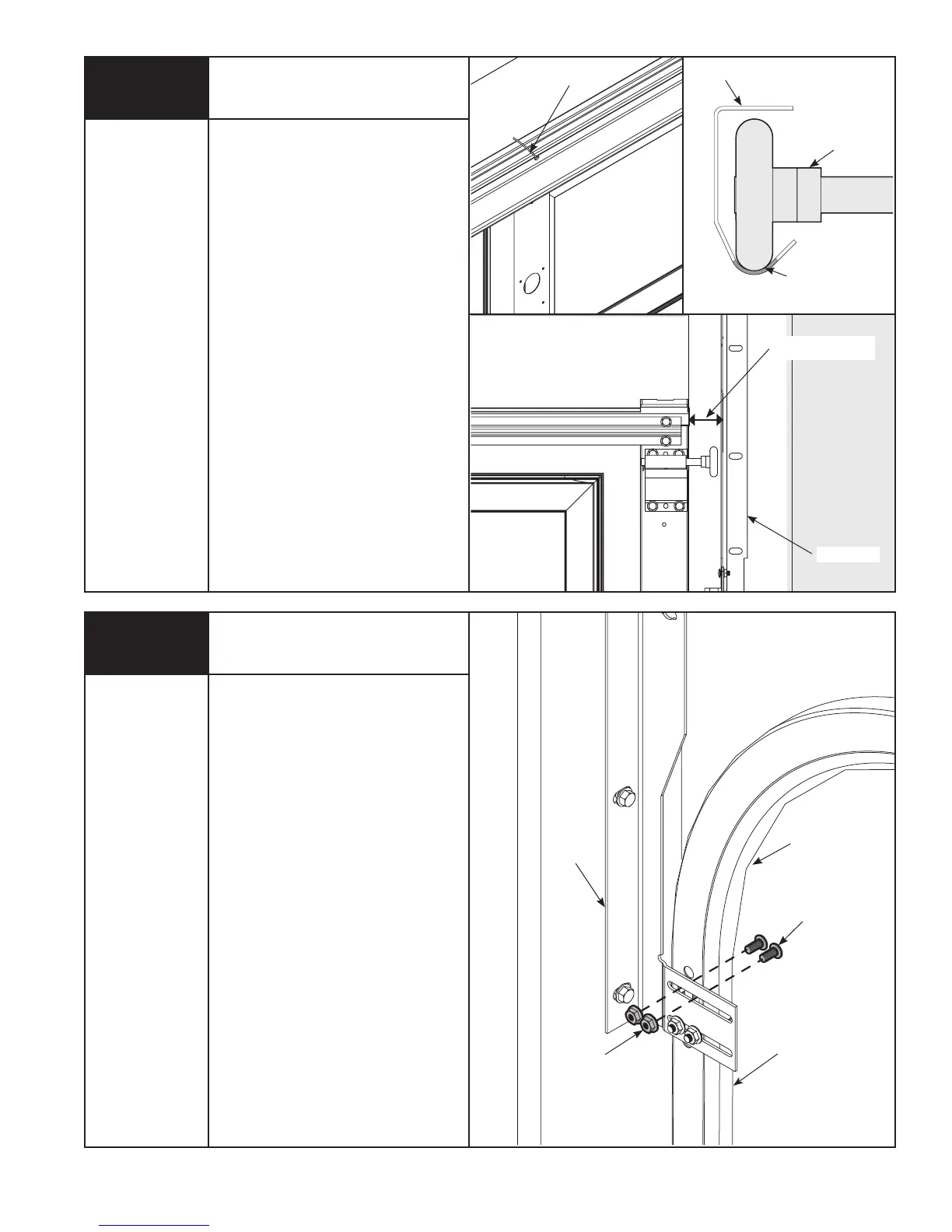

(2) 1/4”- 20 FLANGE

HEX NUTS

VERTICAL TRACK

HORIZONTAL

TRACK

(2) 1/4”- 20 X 5/8”

CARRIAGE BOLTS

To install horizontal track, place the

curved end over the top roller. Align

the bottom of the horizontal track with

the vertical track. Hand tighten the

horizontal track to the flagangle with (2)

1/4”- 20 x 5/8” carriage bolts and (2)

1/4”- 20 flange hex nuts.

Level the horizontal track assembly and

bolt the horizontal angle to the slot in

the flagangle using

(1) 3/8”- 16 x 3/4” hex head bolt and (1)

3/8”- 16 hex nut. Repeat for other side.

Remove the nail that was temporarily

holding the top section in place,

installed in Step 12.

IMPORTANT: FAILURE TO REMOVE NAIL

BEFORE ATTEMPTING TO RAISE DOOR

COULD CAUSE PERMANENT DAMAGE

TO TOP SECTION.

13

9/16” Socket

7/16” Socket

Ratchet Wrench

9/16” Wrench

Level

Hammer

Flat Tip

Screwdriver

Attaching Adjustable Flagangle

to Horizontal Track

BETWEEN THE FLAGANGLES MUST BE

DOOR WIDTH PLUS 3-3/8” (86MM) TO

3-1/2” (89 MM) FOR SMOOTH, SAFE

DOOR OPERATION.

Complete the vertical track installation

by securing the center jamb bracket(s)

and tightening the other lag screws.

Push the vertical track against the

rollers so that the rollers are touching

the deepest part of the curved side of

the track (see illustration). Tighten all

the carriage bolts and nuts.

Repeat for opposite side.

Top Section Continued...

Loading...

Loading...