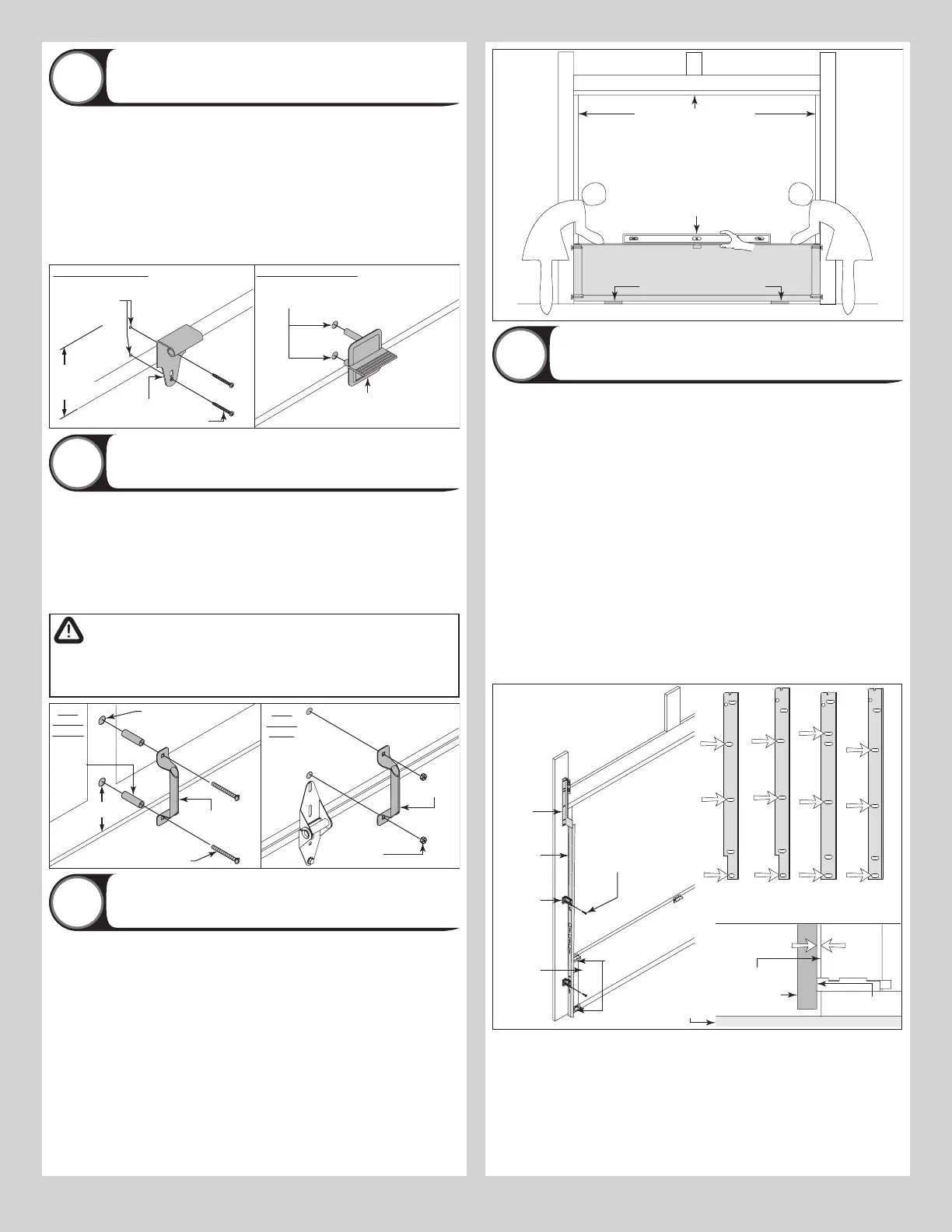

Attaching Step Plate To Bottom Section

7

On the inside of the bottom section, locate the vertical center of the door. Center the inside

step plate vertically no higher than 8” from the bottom of the door to the top of the step plate.

IMPORTANT: DO NOT MOUNT THE STEP PLATE HIGHER THAN 8” FROM THE BOTTOM OF

THE SECTION.

Using the inside step plate’s second top most hole and bottom hole as a template, drill 7/16”

diameter holes through the entire section.

IMPORTANT: BE EXTREMELY CAREFUL TO KEEP DRILL STRAIGHT.

Now insert the outside step plate into the holes through the front of the door, mounting the

two step plates back to back. Secure step plates together with two No. 8 screws through the

inside step plate and into the outside step plate.

Inside step plate

(2) #8 Screws

8” Max.

mounting

height

Outside

step plate

7/16”

Diameter holes

Drill (1) 7/16”

diameter hole

at each marked

location

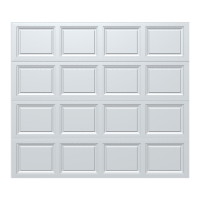

Attaching Lift Handles

8

Locate the vertical center of the lock (second) section of the door and position the lift

handle’s bottom hole 4” from the bottom of the lock section along the vertical center on the

outside of the door. Use the holes in the lift handle as a template to mark the hole locations.

IMPORTANT: THE LIFT HANDLE AND THE STEP PLATE NEED TO BE VERTICALLY ALIGNED.

Drill 9/32” diameter holes through the section at each marked location. Enlarge the holes

from outside the door to 1/2” diameter through the section. Assemble the outside and inside

lift handles to the section using (2) 1/4” - 20 x 2-1/2” carriage bolts and (2) 1/4” - 20 hex

nuts and spacers.

WARNING

TO AVOID POSSIBLE INJURY, LIFT HANDLES THAT ARE INSTALLED

WITHIN 4 INCHES (102MM) OF A SECTION INTERFACE SHALL PROMOTE

VERTICAL ORIENTATION OF THE HAND.

holes

4”

(2)

Spacers

(2) 1/4”-20 x 2-1/2”

Carriage bolts

section

outside

section

inside

(2) 1/4”-20

Hex nuts

Lift handle

Positioning Bottom Section

9

Center the bottom section in the door opening. Level the section using wooden shims (if

necessary) under the bottom section. When the bottom section is leveled, temporarily hold it

in place by driving a nail into the jamb and bending it over the edge of the bottom section on

both sides.

Weather seal (If applicable)

Level

Bottom section

Wooden shims (If necessary)

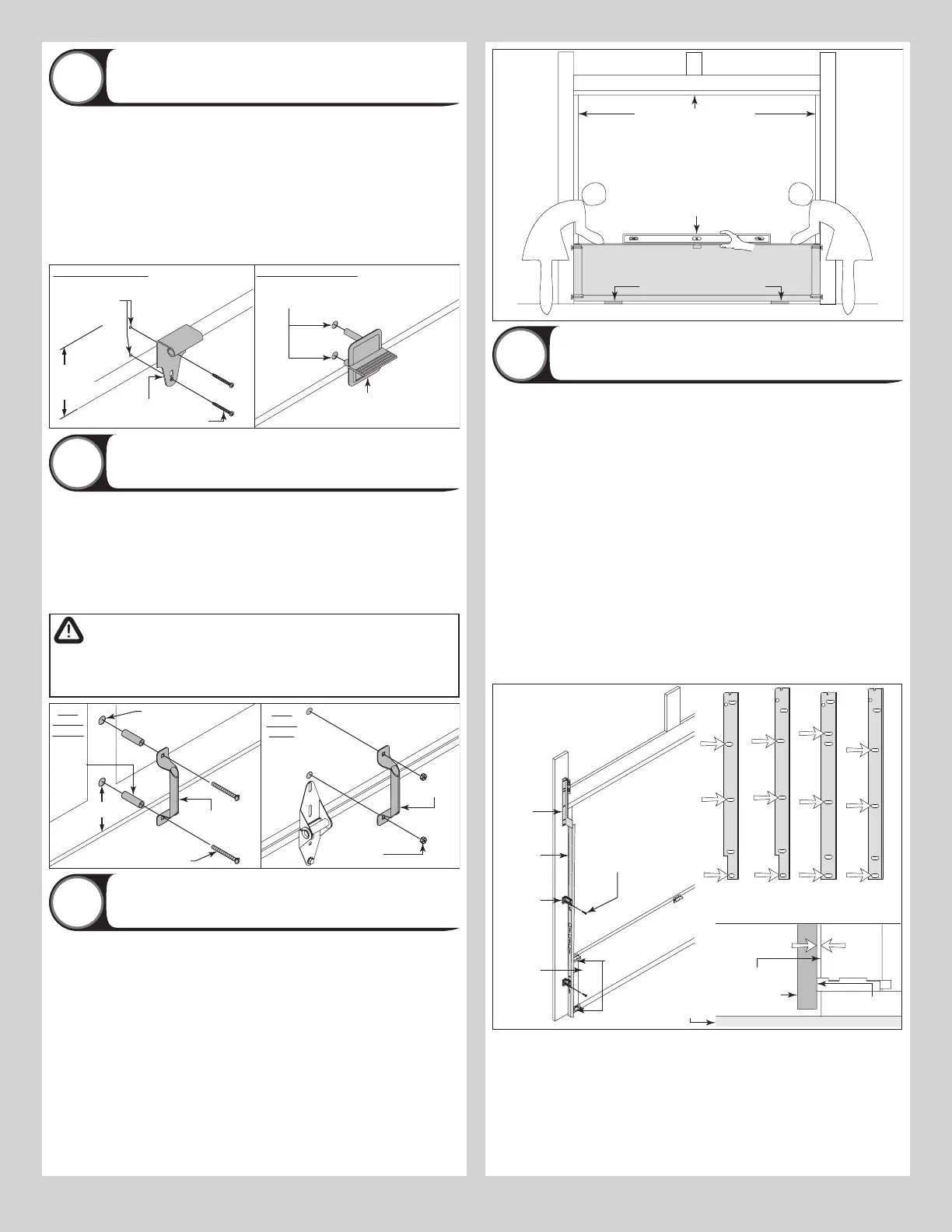

Attaching Vertical Tracks To Jambs

10

NOTE: Depending on your door, you may have Quick Install Flag Angles, Fully Adjustable Flag

Angles, Riveted Vertical Track Assemblies or you may have Angle Mount Vertical Track As-

semblies. Refer to Package Contents / Breakdown of Parts, to determine which Flag Angles /

Vertical Track Assemblies you have.

IMPORTANT: IF YOUR DOOR IS TO BE INSTALLED PRIOR TO A FINISHING CONSTRUCTION

OF THE BUILDING’S FLOOR, THE VERTICAL TRACKS AND THE DOOR BOTTOM SECTION

ASSEMBLY SHOULD BE INSTALLED SUCH THAT WHEN THE FLOOR IS CONSTRUCTED, NO

DOOR OR TRACK PARTS ARE TRAPPED IN THE FLOOR CONSTRUCTION.

IMPORTANT: THE TOPS OF THE VERTICAL TRACKS MUST BE LEVEL FROM SIDE TO SIDE.

IF THE BOTTOM SECTION WAS SHIMMED TO LEVEL IT, THE VERTICAL TRACK ON THE

SHIMMED SIDE MUST BE RAISED THE HEIGHT OF THE SHIM.

NOTE: Make sure the counterbalance lift cable is located between the track rollers and the

door jamb.

Starting on the left hand side of the bottom section, remove the nail. Position the left hand

vertical track assembly over the track rollers of the bottom section and install, as shown. Drill

3/16” pilot holes into the door jamb for the lag screws.

FOR QUICK INSTALL FLAG ANGLES OR FULLY ADJUSTABLE FLAG ANGLES: Loosely

fasten jamb brackets and flag angle to the jamb using 5/16” x 1-5/8” lag screws. Tighten lag

screws, securing the bottom jamb bracket to jamb, maintain 3/8” to 5/8” spacing, between

the bottom section and vertical track. Hang counterbalance lift cable over flag angle. Repeat

same process for other side.

Vertical

track

assembly

Jamb

bracket

Flag

angle

Flag angle lag screw locations

5/16” x 1-5/8”

Lag screws

Bottom

section

Track

rollers

12R FA

3/8” to 5/8”

Spacing

Bottom section

15R QI12R QI

Floor

Track roller

15R FA

Vertical track

FOR RIVETED VERTICAL TRACK ASSEMBLY: Loosely fasten jamb brackets and flag angle

to the jamb using 5/16” x 1-5/8” lag screws. Tighten lag screws, securing the bottom jamb

bracket to jamb, maintain 3/8” to 5/8” spacing as shown between the bottom section and

vertical track. Hang counterbalance lift cable over flag angle. Repeat same process for other

side.

FOR ANGLE MOUNT VERTICAL TRACK ASSEMBLY: Loosely fasten the slots in the wall

angle to the jamb using 5/16” x 1-5/8” lag screws. Tighten lag screws, securing the bottom

slot in the wall angle, maintain 3/8” to 5/8” spacing as shown between the bottom section

and vertical track. Hang counterbalance lift cable over angle mount. Repeat same process for

other side.

8

Loading...

Loading...