.

26 © Weldclass 2019 | E.&O.E. | Edition 1.0 2019.05

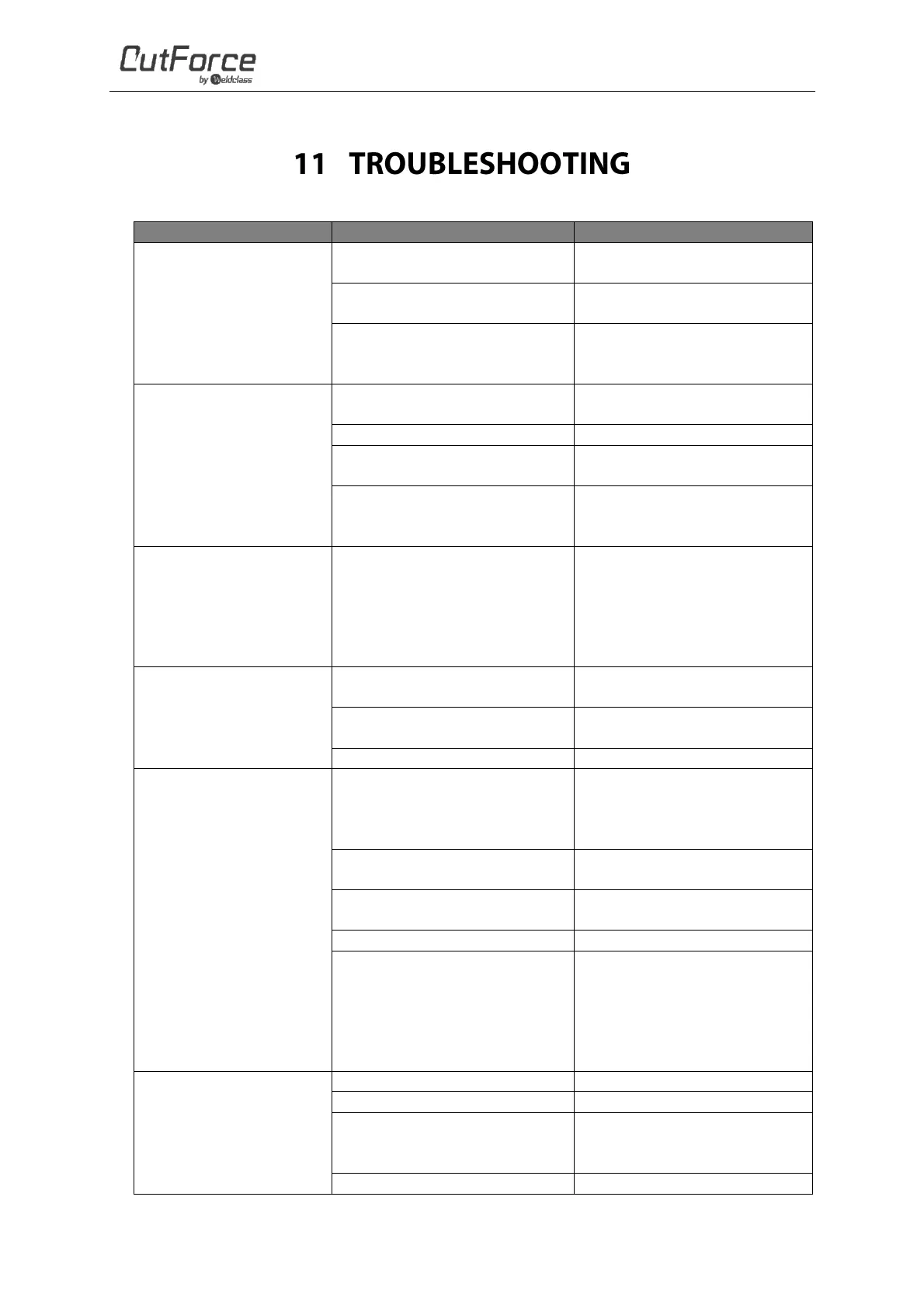

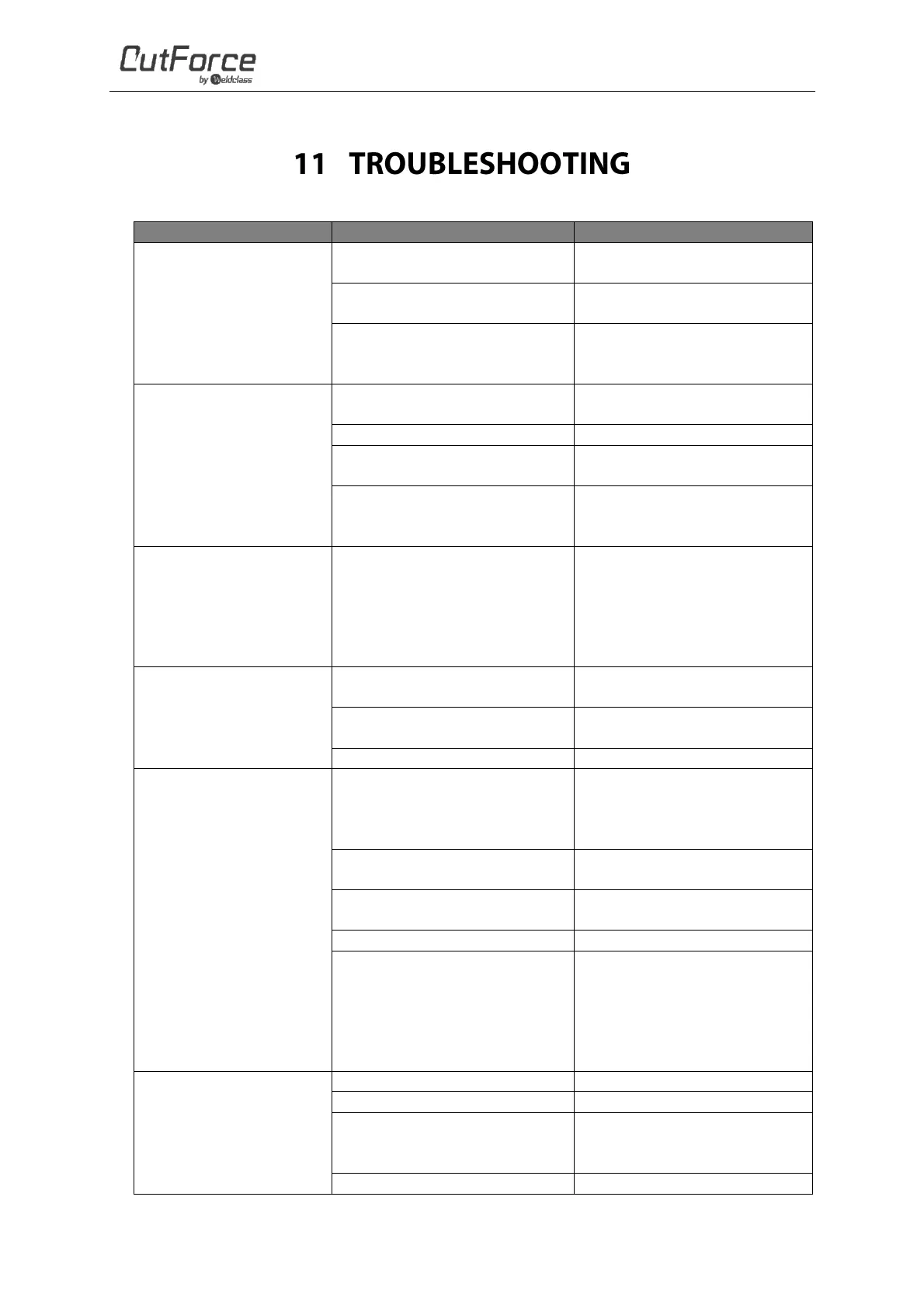

Torch will not come on/arc

Turn power switch to the ON

position

Air supply is not of sufficient

volume or pressure

Check air supply (60-80psi, at

least 3.5cfm required)

Attach earth clamp to work piece

or to steel table with work piece

securely clamped to table

Sparks are shooting upward

instead of down through

the material

Plasma torch is not piecing the

material

Increase amperage and/or reduce

speed

Torch may be too far away from

the material

The tip should be approximately

2mm above the material

Material may be too thick for

capacity of plasma

Several passes may be necessary

or find some other method to cut

the material

Beginning of cut not

completely pierced

Possible earth connection

problem

Check earth clamp is securely

connected to the bare material.

Check earth lead is securely

plugged into machine

Ensure earth lead is it good

condition.

Material building up heat

Allow material to cool then

continue cutting

Incorrect speed / technique

Refer to 7.7 - Reducing Dross for

Clean Cuts

Replace with new torch parts

Arc stops in middle of cut

Check air supply (60-80psi, at

least 3.5cfm required).

May have to wait for compressor

to build up pressure again.

Cutting speed is too slow

Increase cut speed until problem

solved

Tip to material distance is too high

Tip should be approximately

2mm off the material

Replace with new torch parts

Possible earth connection

problem

Check earth clamp is securely

connected to the bare material.

Check earth lead is securely

plugged into machine

Ensure earth lead is it good

condition.

Material may be too thick for

capacity of plasma

Several passes may be necessary

or find some other method to cut

the material

Replace with new torch parts

Loading...

Loading...