Weldmatic 215Operators Manual

Model No. CP111-0, Iss A 02/05 11

Quality, Reliability, Performance

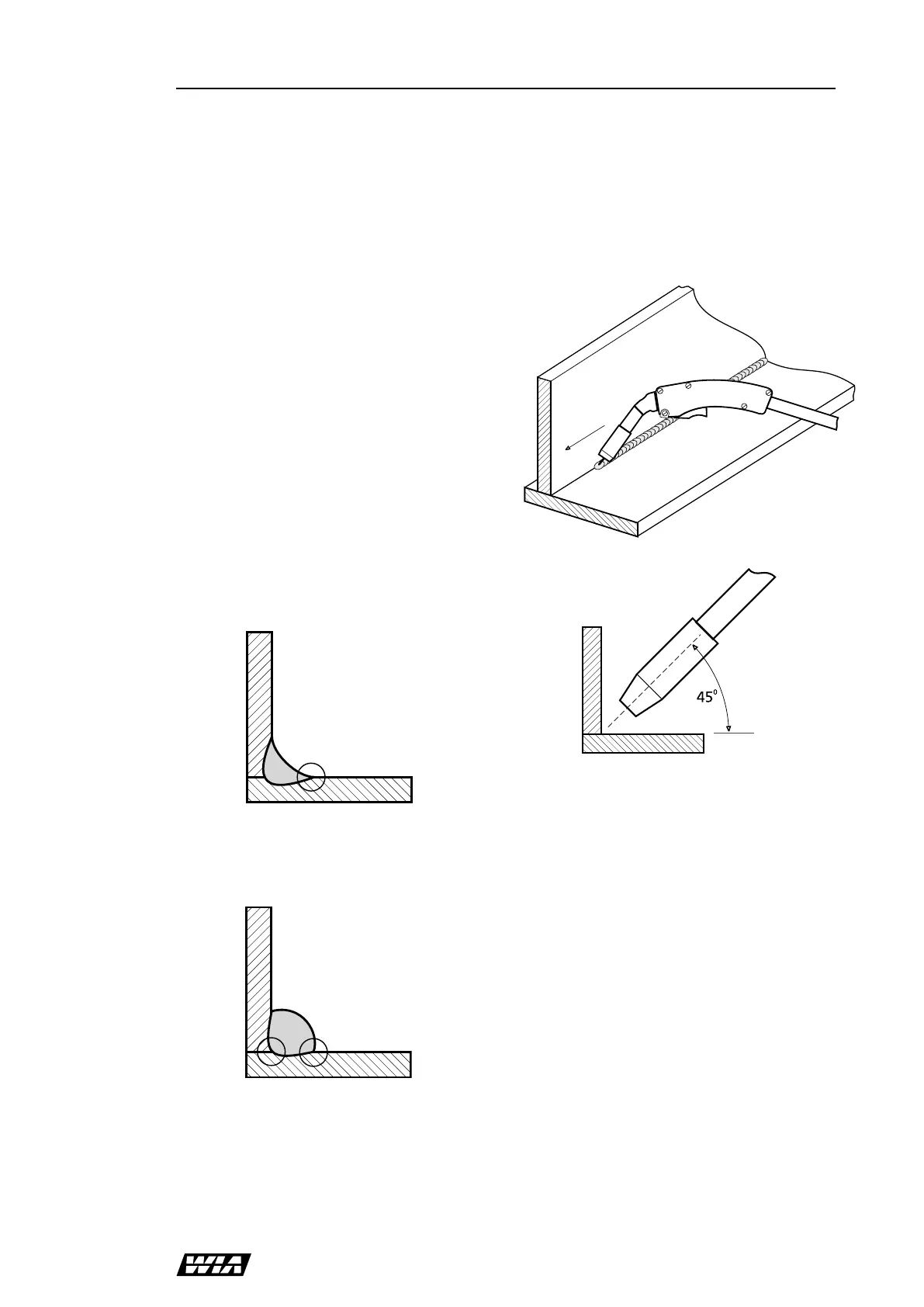

Fig 4 “Good” Weld

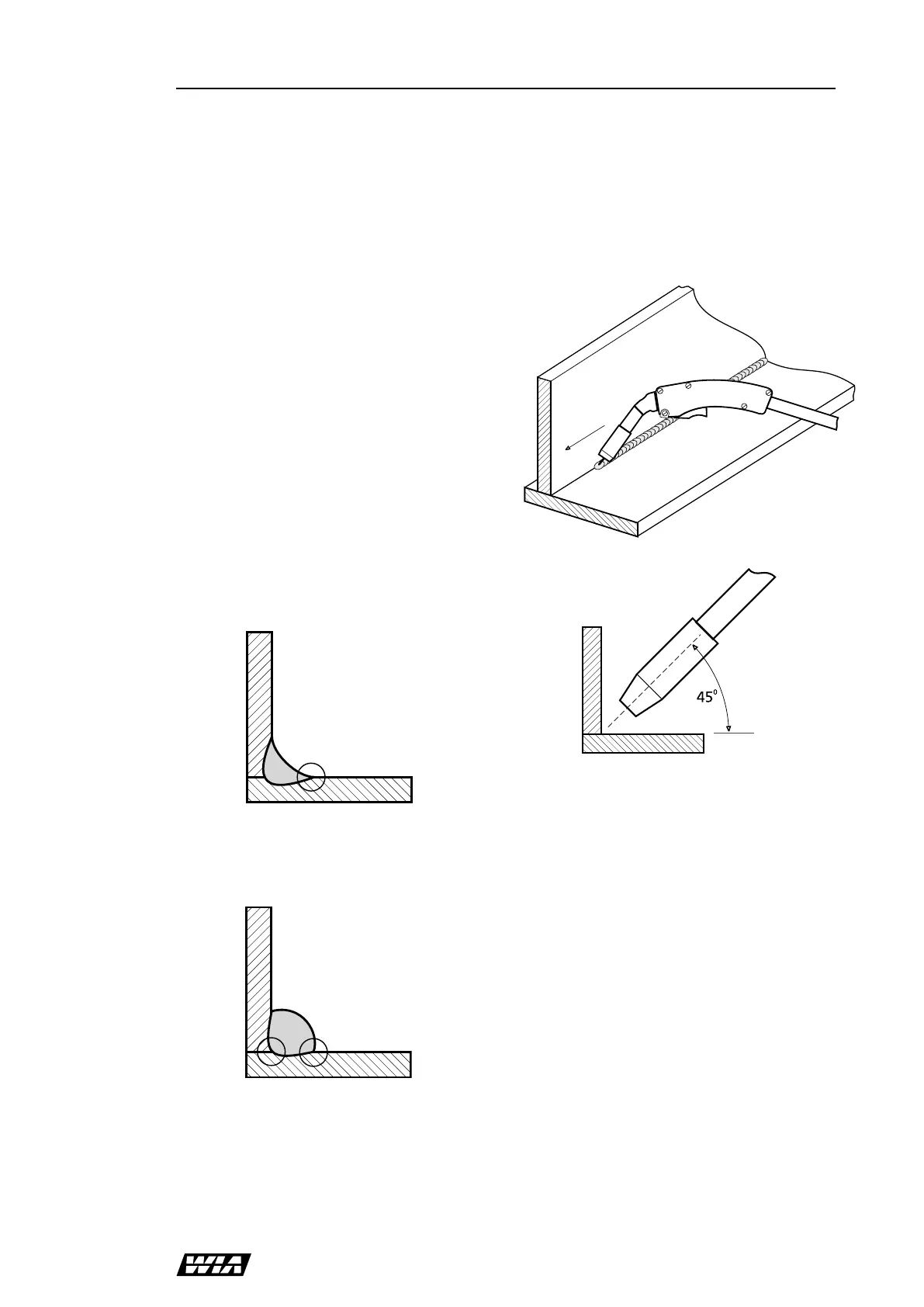

Fig 5 “Bad” Weld

Fig 6 Gun Position

Gun Position

For “down hand” fillet welding, the gun is

normally positioned as shown in Figure 6 below

with the nozzle end pointing in the direction of

travel.

If the voltage is too low the wire will stub and

stutter, and there will not be a steady arc. If

the voltage is too high the arc will be long with

metal transfer occurring as a series of large

droplets.

Important: Do not operate the Voltage

Control switches during welding.

The weld setting should be chosen to suit the

application and the thickness of the metal to

be welded. It is important to check that the

deposited weld provides sufficient strength to

suit the application.

A “good” weld will have the characteristics

illustrated in Figure 4. The weld has penetrated

into the parent metal, fusing the root of the

joint where the two plates meet, and the weld

blends smoothly into the side walls.

A “bad” weld is shown in Figure 5. The weld

has not penetrated the joint root, and there is

poor side wall fusion. This lack of fusion would

normally be corrected by increasing the arc

voltage, or by increasing both wirefeed speed

and arc voltage to achieve a higher current

weld setting.

Loading...

Loading...