Weldmatic 215Operators Manual

Model No. CP111-0, Iss A 02/05 9

Quality, Reliability, Performance

The quality of the consumable wire

greatly affects how reliably a gas metal

arc welder will operate. For best results

when welding mild steel, we recommend

quality WIA AUSTMIG ES6. Dirty, rusty

or kinked wire will not feed smoothly

through the gun cable and will cause

erratic welding. Deposits from the wire

will clog the gun cable liner requiring it

to be replaced prematurely.

Fitting the gas cylinder

Place the gas cylinder on the tray at the rear of

the welder. Retain the cylinder with the chain

provided.

Fit the gas regulator to the cylinder. DO NOT

apply grease or oil to these joints.

Fit the end of the gas inlet hose from the back

of the power source to the connector supplied

with the gas regulator, and secure with the

clamp also supplied.

Fitting The Gun and Cable Assembly

The supplied BERNARD gun/cable assembly is

equipped with a ‘Euro’ wirefeeder connector

which incorporates all required connection

points for welding current, shielding gas and

gun switch control.

To attach the gun/cable assembly to the

wirefeeder mechanism, engage the mating

parts of the male and female Euro connectors,

then rotate the locking ring clockwise to firmly

secure the connection.

Fitting the Consumable Wire

Place the spool of welding wire onto the spool

holder. The location pin should mate with a

hole provided on the wire spool body. Fit the

spool retaining ‘R’ clip supplied. Check the

adjustment of the spool brake, which should

be set to prevent over run of the wire spool at

the end of a weld, without unduly loading the

wirefeed motor. The braking can be adjusted

by the Nyloc nut using a 15/16” AF or 24mm

socket wrench.

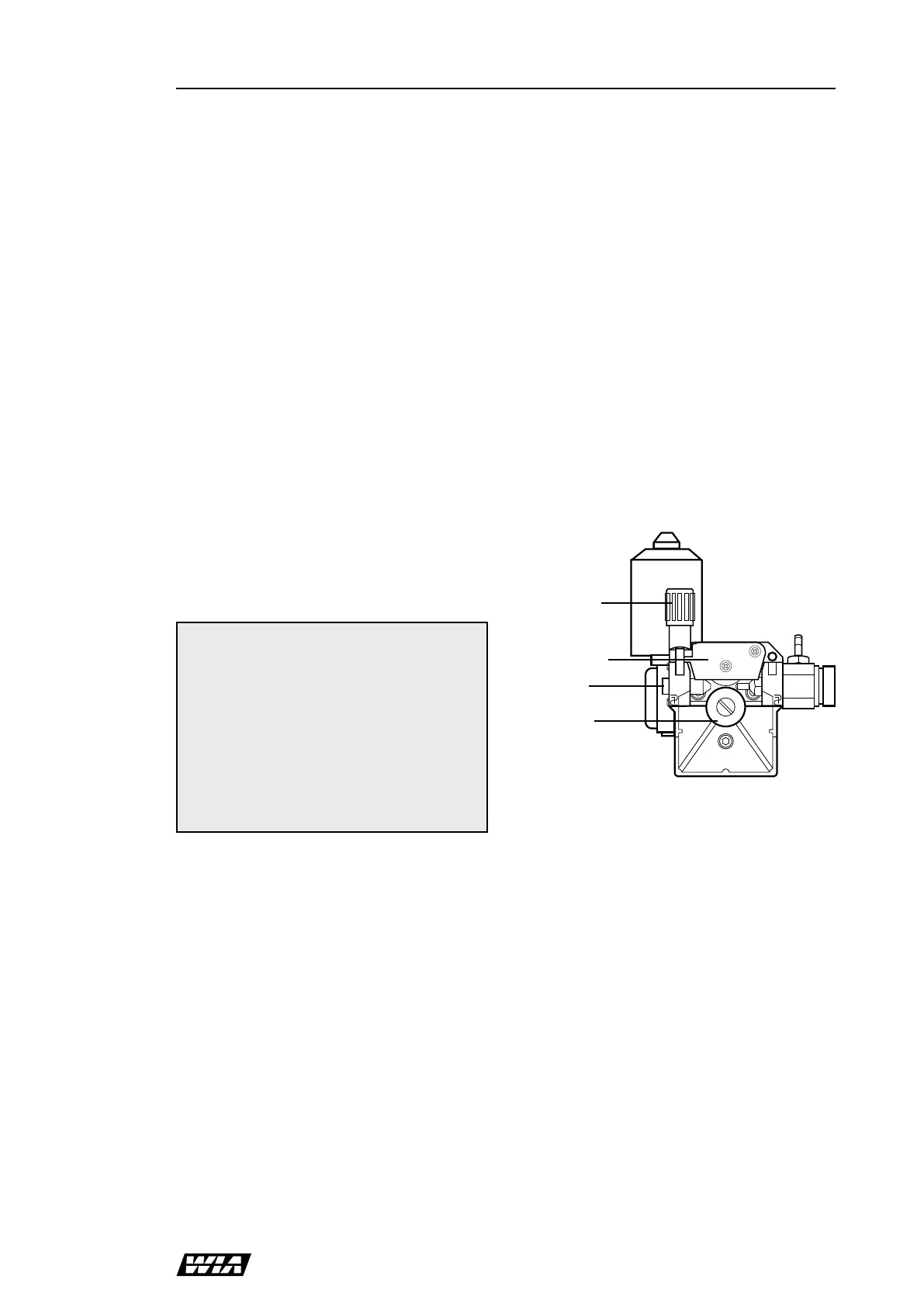

Feeding the Consumable Wire

At the wirefeed assembly, release the

compression screw and rotate the top roller

arm to the open position. The end of the

welding wire can now be passed through the

inlet guide, over the bottom driven roller, and

into the output wire guide tube. Check that the

drive roll groove is correct for the wire in use.

The appropriate size is stamped on the visible

side of the installed roller. Check also that the

correct size contact tip is fitted at the gun end.

Feed roller and tip details are shown in Section

11 of this manual.

Return the pressure arm to the closed position

and adjust the compression screw to provide

sufficient clamping of the drive roll to achieve

constant wirefeed. Do not over tighten.

With the equipment energised, operate the

gun switch to feed wire through the gun cable.

Compression

screw

Top roller arm

Inlet guide

Groove size

0.9

Loading...

Loading...