14

OPERATION

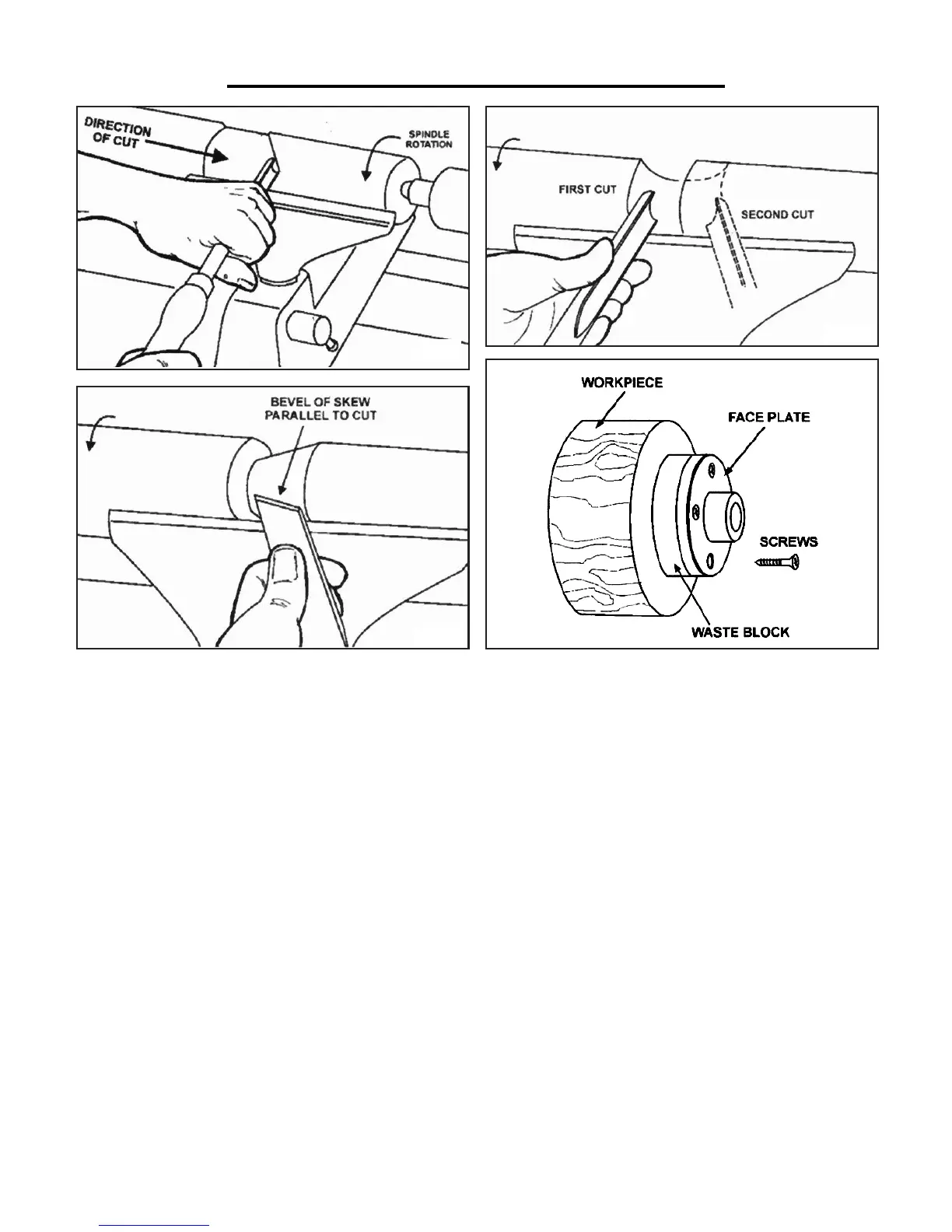

Fig. T

Fig. U

Fig. V

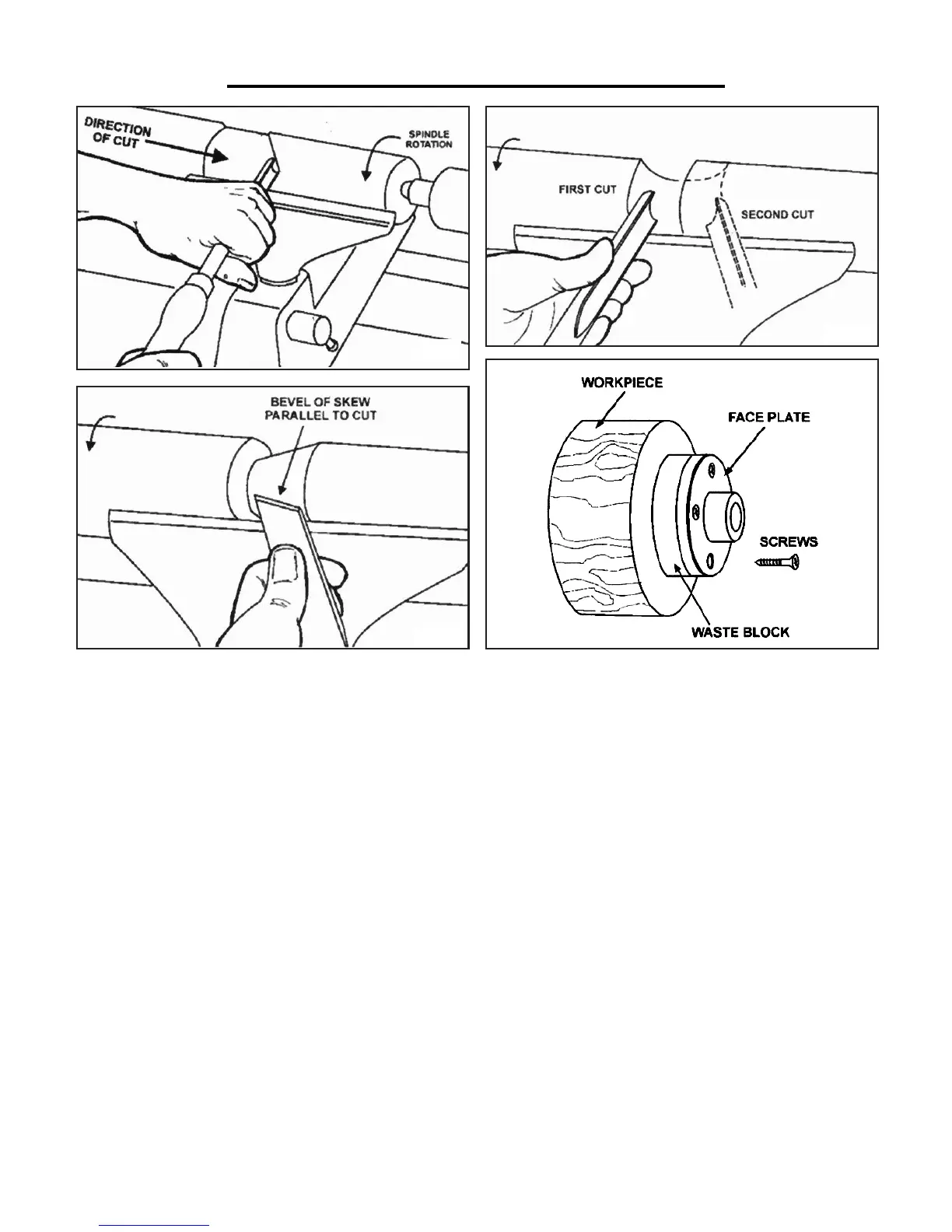

MOUNTING ON THE FACE PLATE

Use of the face plate is the most common for holding a block of wood for turning bowls and plates. This is an

alternative option for workpieces with diameters that are greater than the 12-inch throat of the lathe.

To mount the stock to the face plate, select a stock that is at least .2 inches (5 mm) larger than each dimension of

the finished workpiece. Always select the largest diameter face plate that can be used for the workpiece at hand.

True one of the surfaces of the workpiece for mounting against the faceplate. Using the face plate as a template,

mark the location of the mounting holes on the workpiece and drill pilot holes of 8 mm in diameter.

If the mounting screws on the face plate interfere with the workpiece, a glue or waste block can be used (Fig. W).

Make sure the block is of the same diameter as the face plate. Both the waste block and the workpiece should

have flat surfaces for gluing. Glue the block to the workpiece. Avoid using brown paper or newspaper between

the waste block and workpiece. It may work fine if you are using scrapers, but a slight catch with a bowl gouge can

separate the two.

While face plates are the simplest, most reliable method of holding a larger block of wood for turning, chucks can

also be used. A chuck is not a requirement, but is handy when working on more than one piece at a time. Rather

than removing screws, you simply open the chuck and change workpieces. The most popular ones are four jaw

scroll chucks (dovetails) with a variety of jaws to accommodate different size tenons. Most also come with a screw

chuck as well.

Fig. W

Loading...

Loading...