15

MOUNTING THE WORKPIECE BETWEEN SPINDLES (Fig. Q & R)

Spindle turning takes place between the centers of the lathe. It requires a spur center in the headstock and a live

center in the tailstock. Stock for spindles should be straight grained and free of cracks, knots, nails and other de-

fects. A cup center rather than a cone center in the tailstock will often reduce the risk of splitting the stock.

OPERATION - SPINDLE TURNING

WARNING: To prevent serious injury, make sure all the warnings and instructions have been read and

understood before operating this tool.

1. With a combination square, locate and mark the center on each end of the

workpiece. Accuracy is not critical on full rounds but is extremely important

on stock where square sections are to remain. Put a dimple in the stock with

an awl or nail (or use a spring-loaded automatic center punch).

NOTE: Extremely hard woods may require kerfs cut into the ends of the

stock using a band saw, so the wood will accept the spur center and the live

center.

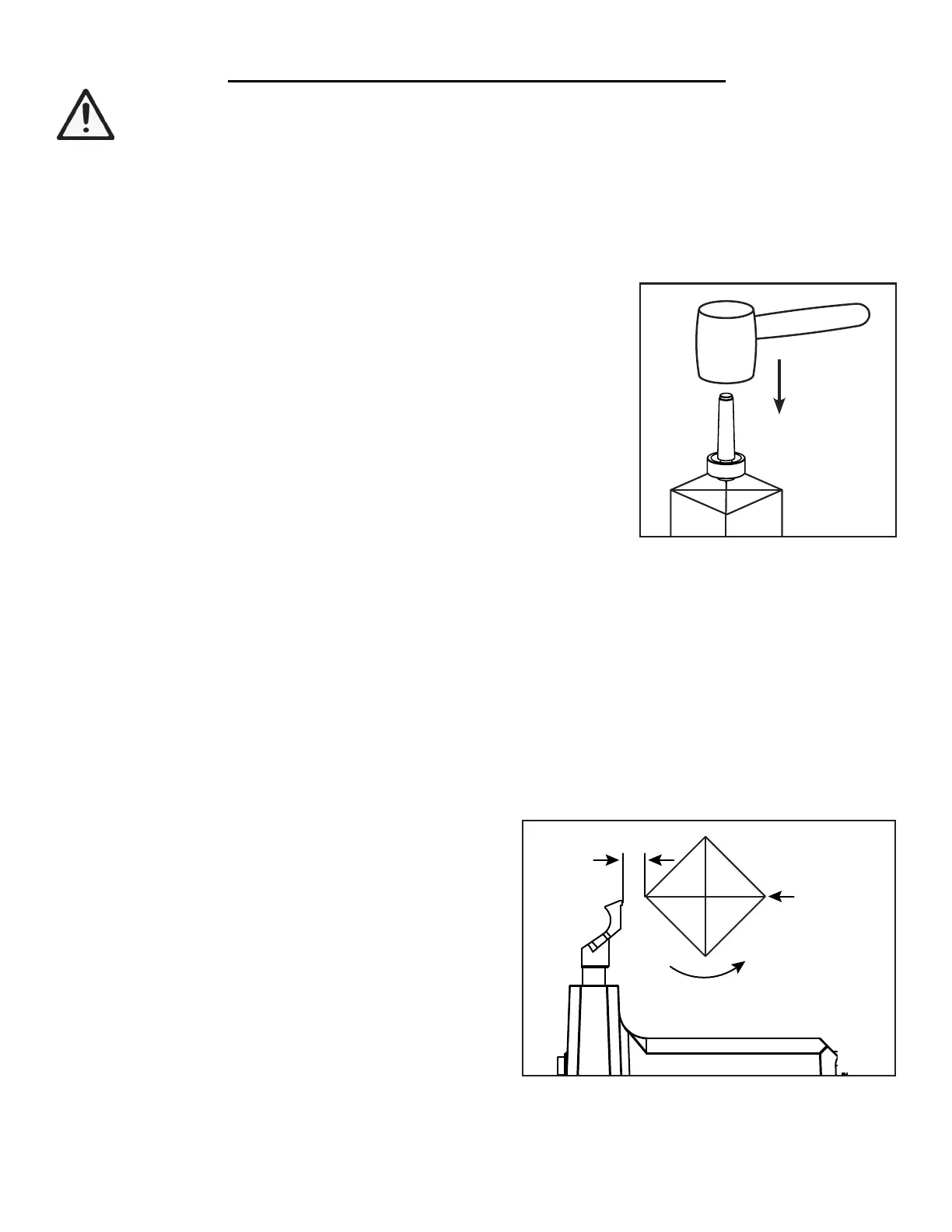

2. Drive the spur center about .1 inches (3 mm) into the workpiece (Fig. Q).

Use a wood mallet or dead blow hammer. Be careful that you do not split the

workpiece. NEVER use a steel face hammer and never drive the workpiece

onto the spur center while it is mounted on the spindle of the lathe.

Fig. Q

Fig. R

3. Clean the tapered end of the spur center and the inside of the headstock spindle. Insert the tapered end of

the spur center (with the attached workpiece) into the headstock spindle. Support the workpiece while loosening

the tailstock locking lever and bringing the tailstock into position. Tighten the tailstock locking lever to lock the

tailstock to the bed.

4. Advance the tailstock quill with the hand wheel in order to seat the live center into the workpiece. Use enough

pressure to secure the workpiece between the centers so that it won’t fly off, but do not use excessive pressure. Ex-

cessive pressure runs the risk of overheating the center bearings and damaging both the workpiece and the lathe.

Tighten the quill locking handle.

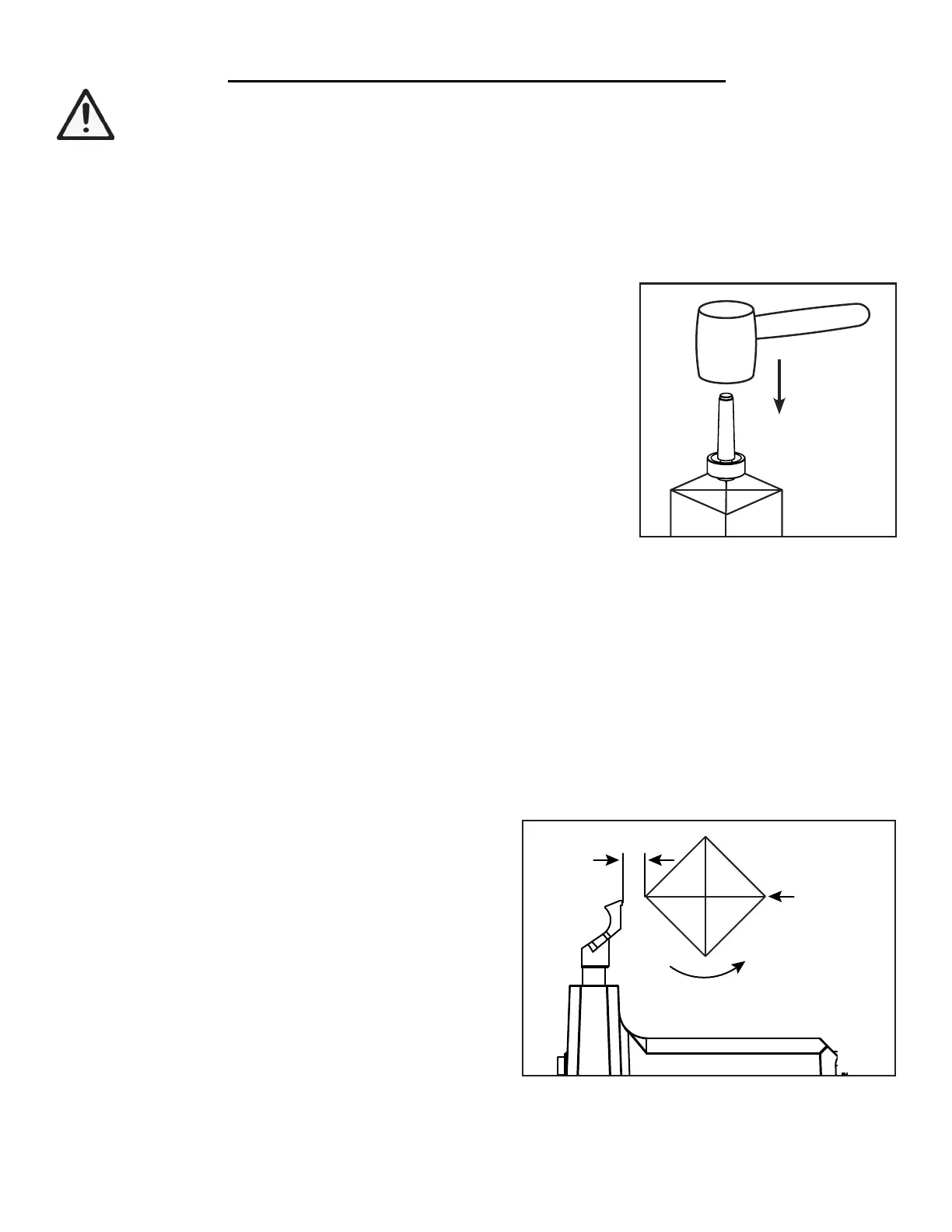

5. Adjust the position of the tool rest to be parallel to the

workpiece. The tool rest height should be just below the cen-

terline and approximately .1 to .2 inches (3 mm to 6 mm)

from the corners of the workpiece to be turned. Secure the

tool rest by tightening the tool rest locking handle and lock-

ing lever (Fig. R).

6. Before switching on the lathe, rotate the workpiece by

hand to check for proper clearance.

3-6mm

Centerline

Direction of Rotation

Loading...

Loading...