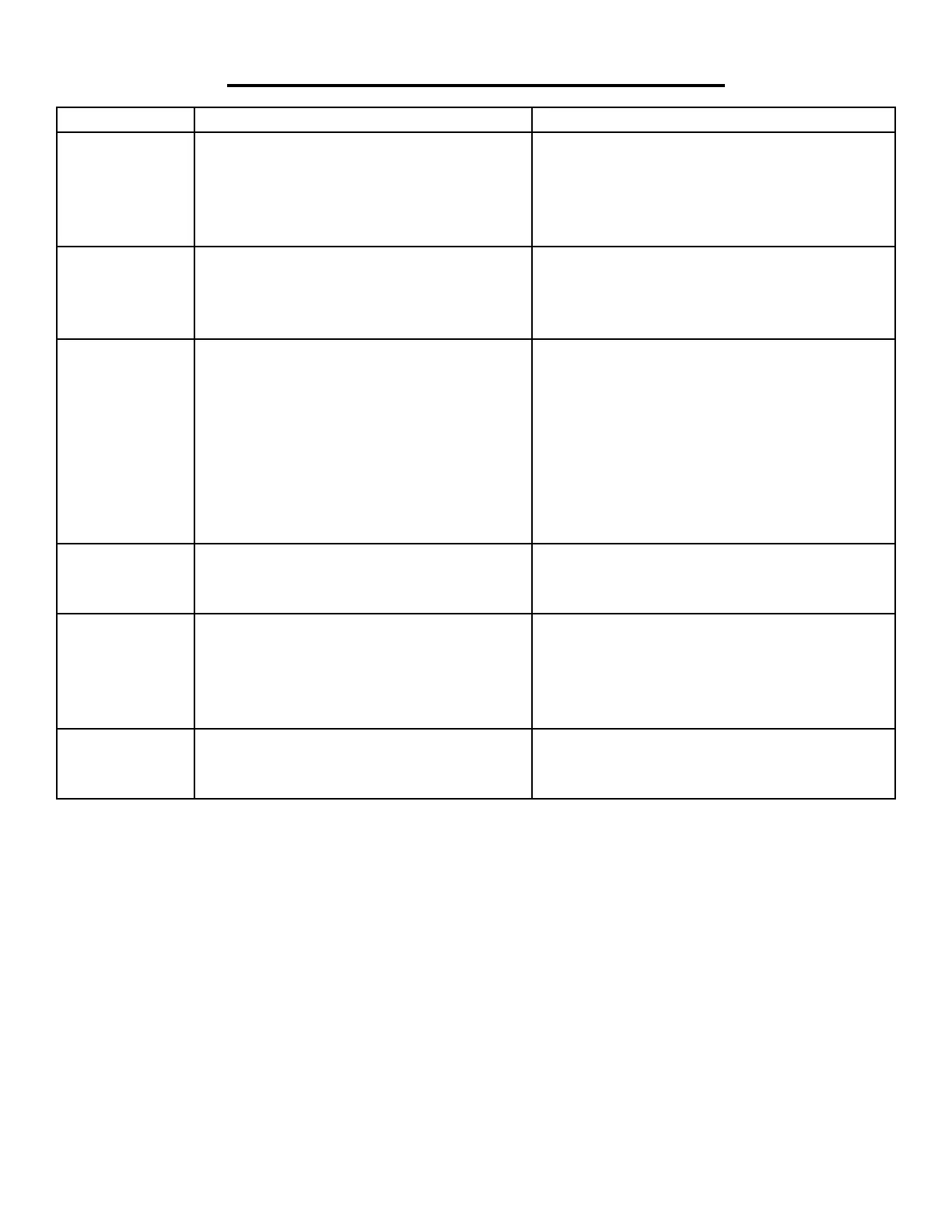

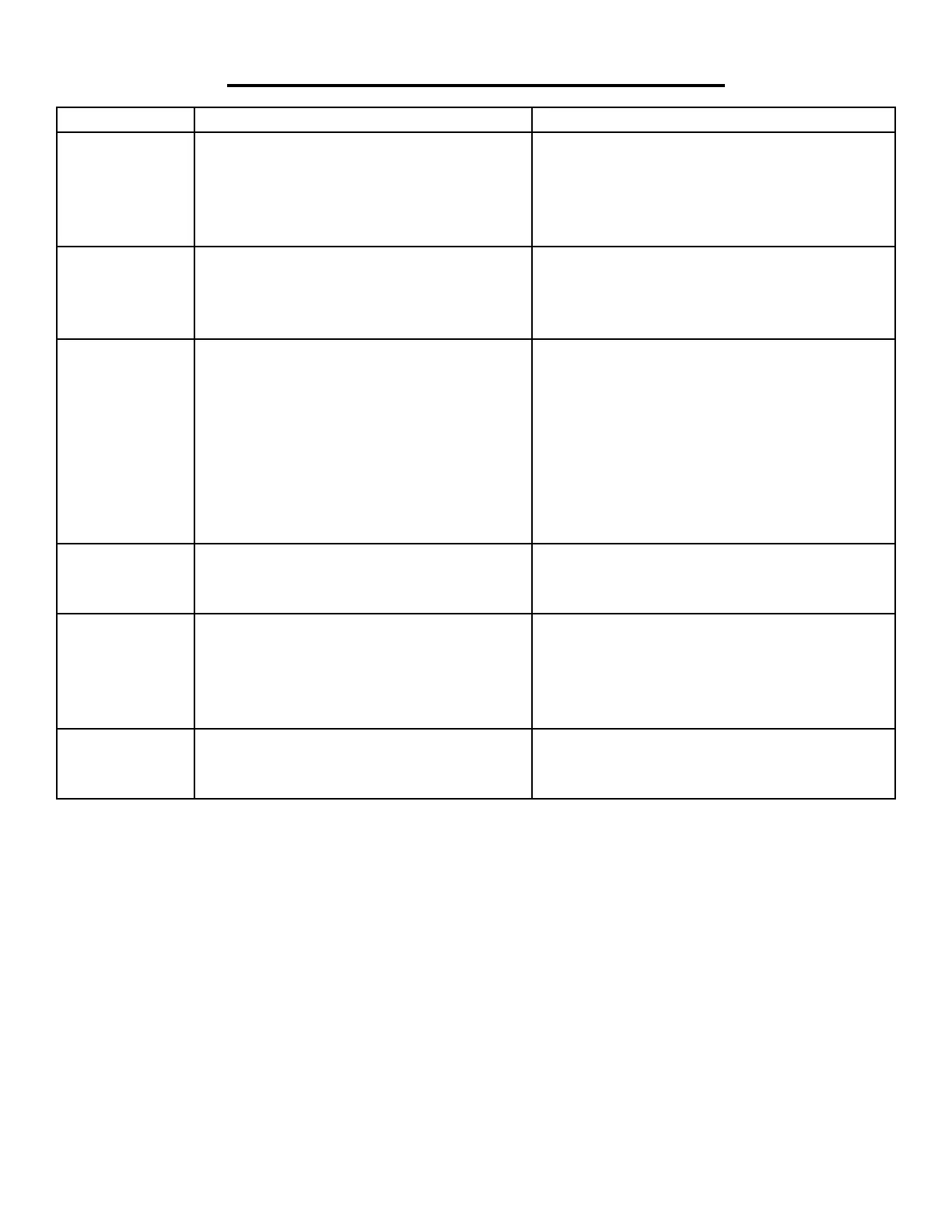

16

PROBLEM CAUSE SOLUTION

The motor

won’t start.

1) Low voltage

2) Loose connections or open circuit in the

motor.

3) Blown fuse/breaker.

1) Make sure the power source is providing the

proper voltage.

2) Inspect the motor for loose or open connec-

tions. Send for servicing if found.

3) Replace the fuse or reset the breaker

The motor is

getting way too

hot.

1) Overloaded motor

2) Extension cord too long or not thick

enough.

1) Reduce load on the motor.

2) Utilize an extension cord with an appropri-

ate gauge and length (or plug the tool directly

into the outlet if possible).

The motor stalls,

causing a blown

fuse or tripped

circuit.

1) Loose connections or short circuit in the

motor.

2) Low voltage.

3) Incorrect fuses or circuit breakers in the

power line.

4) Overloaded motor.

1) Check the connections on the motor for

loose or shorted terminals/worn insulation.

Send for servicing if found.

2) Fix voltage supply; possibly an issue with the

extension cord or possibly the power source.

3) Install the correct fuses or circuit breakers.

Plug tool into an appropriate circuit, matched

with an appropriate fuse/breaker.

4) Reduce the load.

Stropping wheel

performance

decreases

1) Insufficient wheel preparation (lack of oil

and paste)

2) Damaged wheel

1) Prepare the wheel

2) Change out the wheel

Wavy condition

on the surface of

a workpiece

1) Machine is vibrating

2) Workpiece isn’t held in place firmly

3) Wheel face uneven

1) Make sure the machine is securely posi-

tioned on a level surface.

2) Use a holding device to firmly retain the

workpiece.

3) Dress the grinding wheel.

Machine runs

too loud during

operation.

Lack of lubricating grease Add lubricating grease to the gear.

TROUBLESHOOTING

Loading...

Loading...