Seite 15 von 18 WH-1, WH-2, WH-3, WH-4

9.4 Connection of hose coupling to cylinder

9.4.1 Quick couplers (system 50 Mpa) (not included in delivery, Special order)

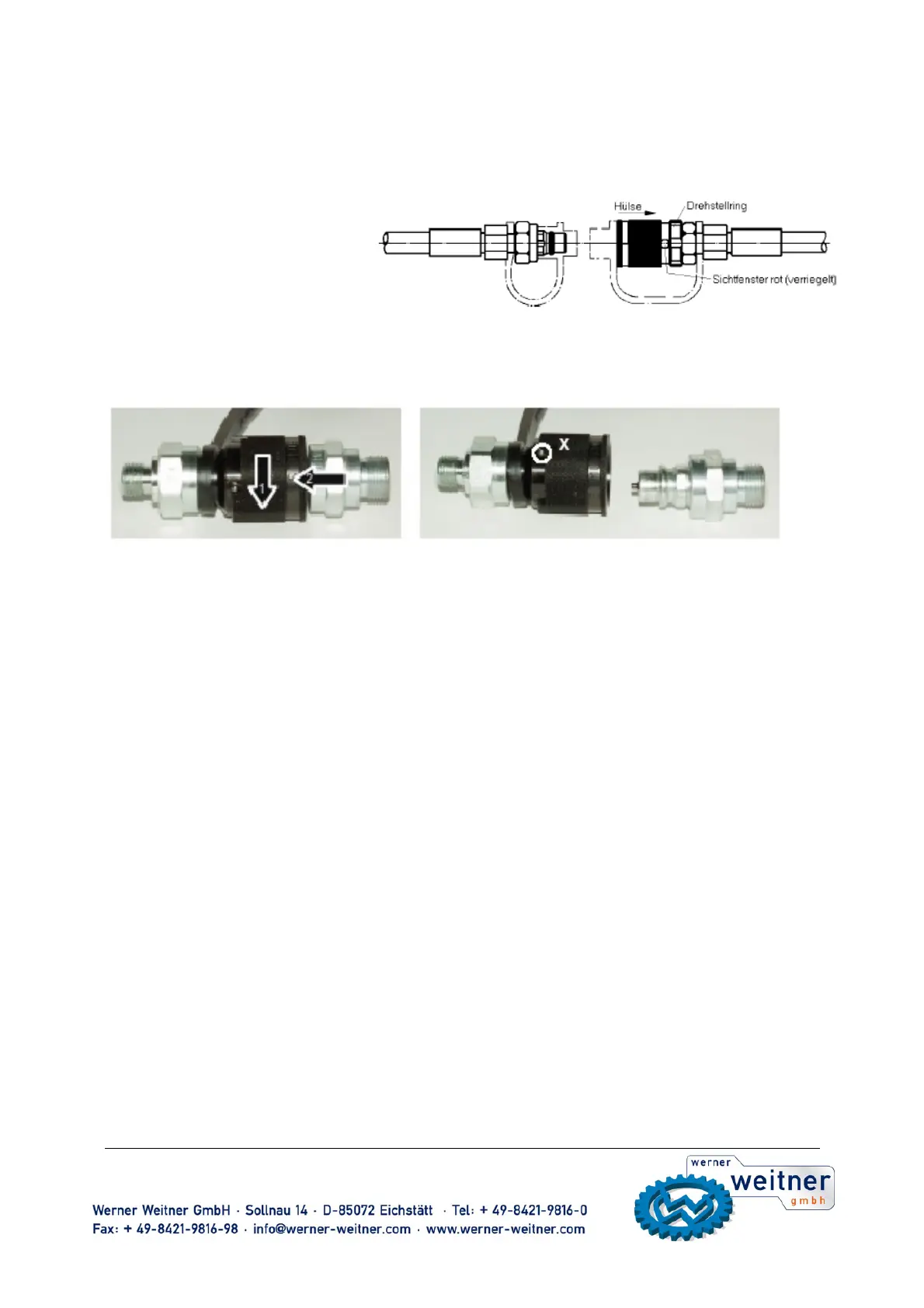

Release mechanism until June 2003

Before coupling, remove the dust protection covers and unlock the connect socket with adjusting ring by turning it. Withdraw the

sleeve and connect plug and socket while holding the sleeve in this position. Release the sleeve and set the showglass to „red“ with

the adjusting ring. Now the

parts are connected and locked. Decoupling is done in the reverse order.

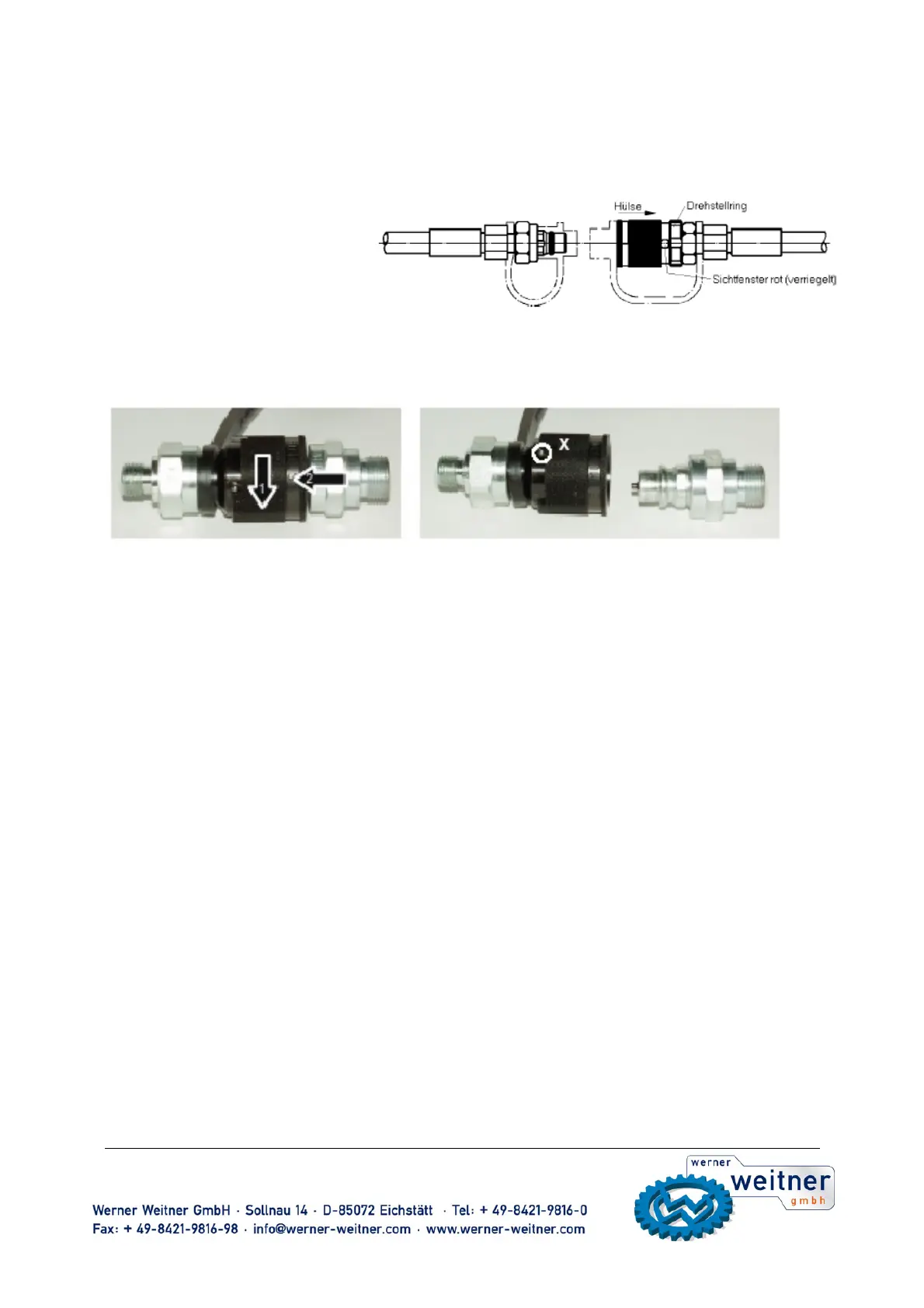

Note regarding the modified release mechanism as of June 2003

When connecting the hoses, be aware of the following basic functions of the quick couplers:

In position X, retract sleeve – plug and socket are uncoupled - the device is coupled in reverse

order. The devices can only be coupled if the hose lines are depressurized.

The supplied dust caps are used to protect the couplers against dirt.

9.4.2 Screw couplers (system 70 Mpa)

- remove dust caps

- connect nipple SKN 2 on the hose with its female counterpart SKM 1 on the cylinder

- turn the threaded sleeve of SKM 1 by hand until it is tightened

10 Lifting a load, or building up pressure

10.1 Safety remarks as to safe use of the hand pump

Caution!

NEVER add extensions to pump handle. Extensions cause unstable pump operation.

Warning!

In certain situations the pump handle can "kick back".

Please ensure that your body does not face the pump frontally.

Note:

To reduce handle effort at high pressure, take short strokes. Maximum leverage is obtained in the last 5 degrees of stroke.

10.3 Observe „Safety measures prior to and during lifting“ as per separate operating manual of your

cylinder (also refer to the operating instructions of the cylinder or device being used).

11 Lowering a load (pressure release)

11.1 Open the oil filler cap (3) on the reservoir a few turns

11.1.1 To retract the piston of the cylinder, open the drain valve of the pump carefully (rotation to the left). Closing the drain valve

(rotation to the right) will interrupt the drain process. By means of fine adjustment of the drain valve, an extremely precise retraction

of the piston of the cylinder is facilitated

11.2 Special function „quick stop“ (must be ordered separately)

If you open the drain valve rapidly (rotation to the left), an existent quickstop only for 50 MPa cylinders StMu61-M (silver) is activated,

i.e. a non-return valve, incorporated in the quick-connect coupling, will prevent the oil from flowing back. While the hose is at zero

pressure, the cylinder remains under pressure. Pump and cylinder can now be separated and the pump can be used elsewhere.

The "quickstop" also serves as a safety valve if for some reason the hose is damaged. The quickstop will in this case prevent the

load from falling.

In order to release the quickstop, the pressure in the cylinder must be increased with a few pump slaps. This will re-open the non-

return valve in the quick-connect plug StNi 6. The draining can now be continued.

Loading...

Loading...