6-1

DIAGNOSIS & TROUBLESHOOTING

• All units that have failed during the first few

days of use, should be checked for loose

connections, or miswiring.

• All checks should be made with a meter

having a sensitivity of 20,000 ohms per volt,

or greater.

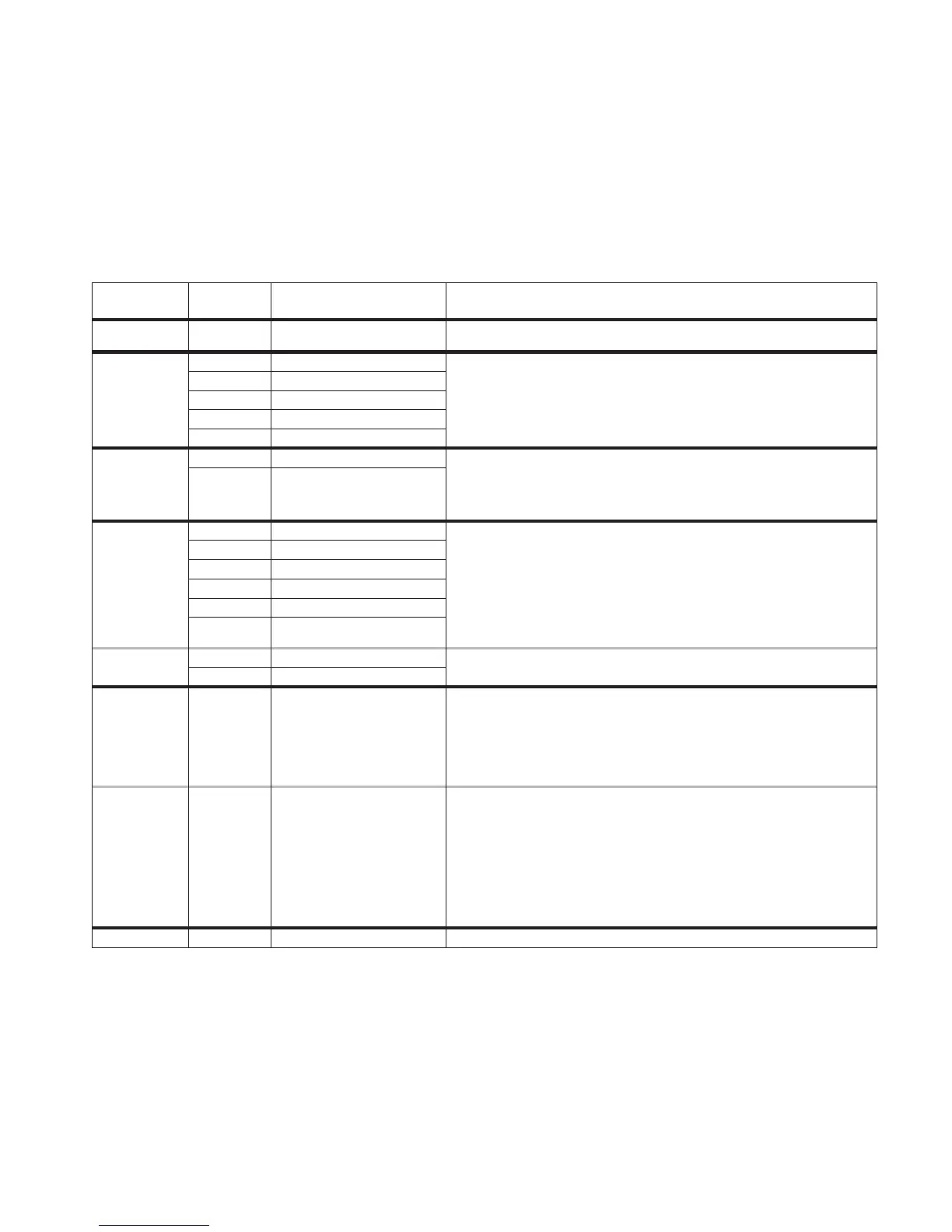

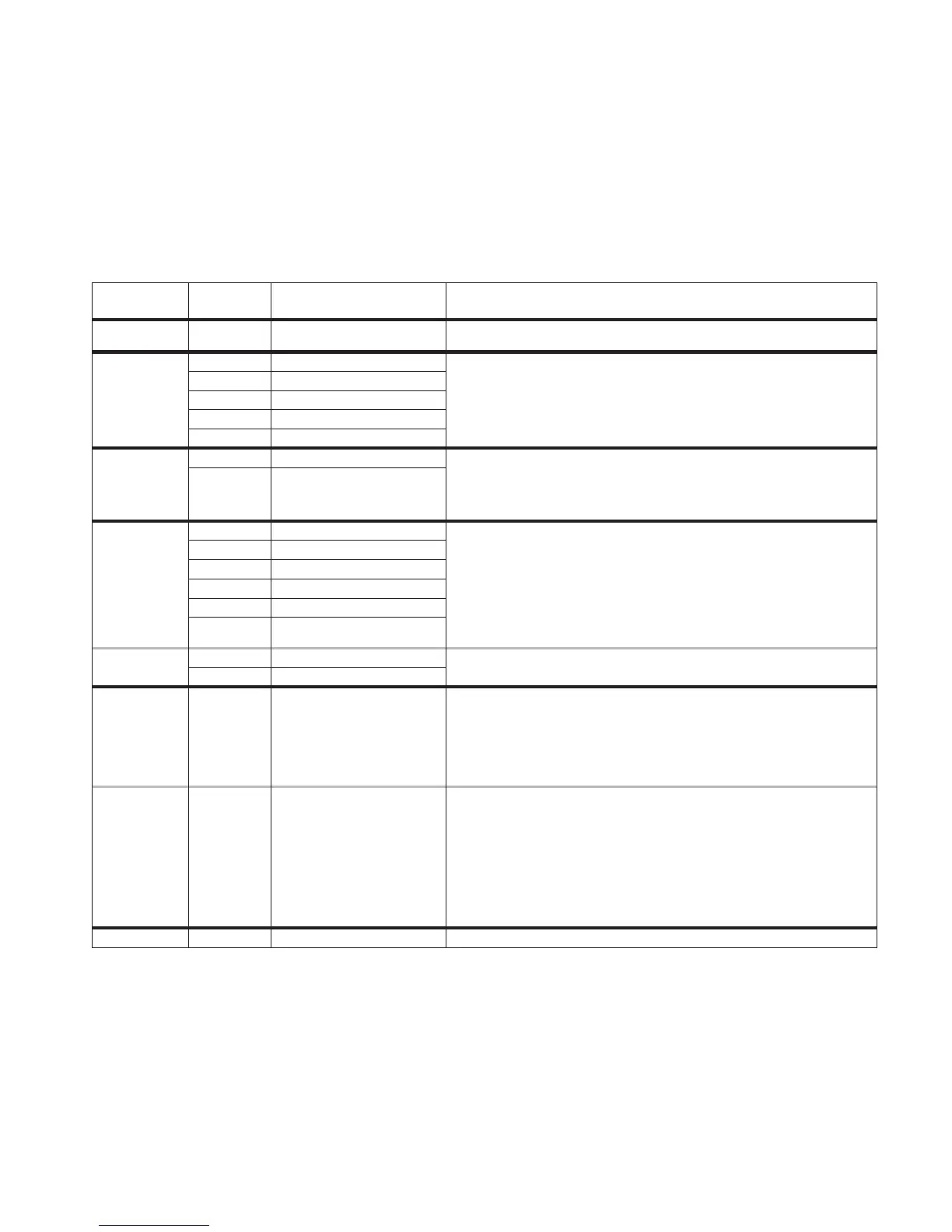

FAILURE/ERROR DISPLAY CODES

TECH SHEET 8522648, REV. A

• All diagnoses of this range must begin with a

normal check of the line voltage, blown fuses,

and failed components.

F1

F0

E0

E0

EEPROM communications

Factory default - not an error 1. No action required.

error

1. Verify failure if not displayed, using

CANCEL/OFF

key. Press key for 5 seconds until last

error code is displayed.

2. Disconnect power longer than 30 seconds.

3. Re-apply power and observe for longer than 1 minute.

4. If failure remains, disconnect power, replace control.

E1

EEPROM checksum error

E2

UL A/D error(s)

E4

Model ID error

E6

Latch signal mismatch error

F2

E0

Shorted key

1. Verify failure if not displayed, using

CANCEL/OFF

key. Press for 5 seconds.

2. Disconnect power.

3. If applicable, ensure membrane tail is seated in connector on back of control.

4. Re-apply power and observe for longer than 1 minute.

5. If failure remains, disconnect power, replace control.

E1

Key tail unplugged

F3

E0

Oven sensor opened - Top

1. Measure sensor value (between connector pins) between 1000 @ 32 F and 2697

@ 900 F (room temperature approx. = 1080 ). If measurement does not correlate to

real temperature, disconnect power, replace sensor and refer to steps 3-5.

Also measure from sensor connector to sensor casing for possible short.

2. Trace wires and connectors to sensor from control, then from sensor back to control. If

all connections are made and no wire damage, refer to step 3.

3. Disconnect power longer than 30 seconds.

4. Re-apply power and observe for longer than 1 minute.

5. If failure remains, disconnect power, replace control, then go back to step 4.

E1

Oven sensor shorted - Top

E2

Bake range over temperature

E3

Clean range over temperature

E4

Oven sensor opened - Top

E5

Oven sensor shorted - Top

F3

E6

Warming drawer sensor open

1. Same corrective action as for other F3 codes, with the exception that the warming

drawer resistance value at room temperature is approx. 100k .

E7

Warming drawer sensor shorted

F5 E0

Door switches do not agree

1. Disconnect power from unit.

2. Check wires and connectors from control to door switch, then from door switch to

control.

3. If no damage to wires or connector, replace door switch.

4. Re-apply power.

5. Press CANCEL PROGRAM and start the clean mode, and observe for one minute to

ensure that operation is normal.

F5 E1

Door latch not operating

1. Verify error code by pressing and holding CANCEL/OFF key for 5 seconds. Momentarily

(less than 5 sec.) press CANCEL key again to remove error code display.

2. Program and start the Clean mode. Observe to see if door locks. If it does not, inspect

the locking mechanism from the solenoid to the latch pawl and door to find the cause

of the problem. If the door is not locking, then 1 minute from the start of the Clean, the

F5 E1 code will again be displayed. Press CANCEL key to remove error code display.

3. Once any mechanical problems with the latch mechanism have been corrected, program

and start a Clean cycle (after, if necessary, clearing F5 E1 error code) to ensure proper

operation of the door lock. Immediately cancel the Clean mode to observe proper

operation of door unlock.

F8 E0

N/A N/A

Ω

Ω

Ω

Ω

°

°

4-DIGIT

DISPLAY

3-DIGIT

DISPLAY

SUGGESTED

LIKELY FAILURE

CONDITION

CORRECTIVE ACTION PROCEDURE

Loading...

Loading...