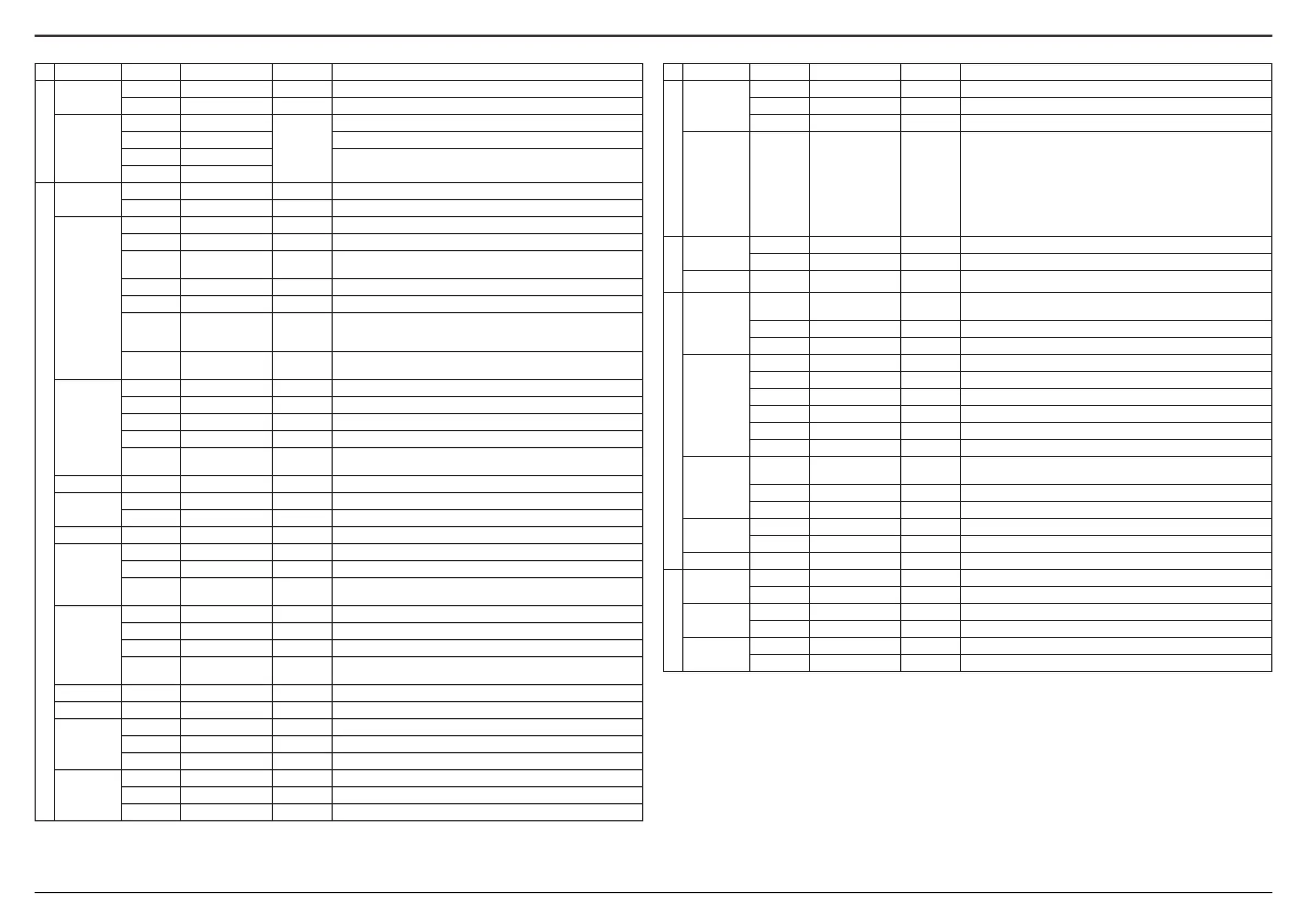

For Service Technician Use Only

COMPONENT TESTING

3-4

n

Multi-Door Freestanding Refrigerator

CONNECTOR FROM TO VOLTAGE CONDITIONS

POWER

P1

P1-1 P1-2 115 VAC CONSTANT 115 VAC

P1-3 P1-4 CONSTANT 115 VAC

P2

P2-1 P2-5 CONSTANT

12.7 VDC

CONSTANT 12.7 VDC

P2-2 P2-6 CONSTANT 12.7 VDC

P2-3 P2-7 CONSTANT 12.7 VDC

P2-4 P2-8

MAIN CONTROL

P1

P1-1 P1-2 115 VAC CONSTANT 115 VAC

P1-2 P1-4 CONDENSER FAN SERVICE TEST 4. 115 VAC IF CONDENSER FAN ON

P2

P2-1 P1-2 115 VAC RC DOOE OPEN 115 V. DOOR CLOSED = 0 V

P2-2 P1-2 AIR BAFFLE FEEDBACK. ACTIVATE SERVICE TEST 3, STEP 3.

P2-3 P1-2 FC DOOR OR LEFT PANTRY DOOR OR RIGHT PANTRY DOOR OR

RIGHT RC DOOR OPEN 115 V, DOORS CLOSED 0 V

P2-4 P1-1 WATER FILTER REMOVED 115 V, FILTER INSTALLED 0 V

P2-5 P1-2 AIR BAFFLE OUTPUT. ACTIVATE SERVICE TEST 3, STEP 3

P2-6 P1-2 HORIZONTAL MULLION HEATER, VERTICAL MULLION HEATER

OUTPUT

01 = 115 V, 02 = 0 V

P2-7 P1-2 FC DEFROST HEATER OUTPUT, THERMO FUSE. SERVICE TEST 6. 115

V

P3

P3-3 P1-2 ICE MAKER WATER VALVE. SERVICE TEST 25. DIGIT 1 = 1 = 115 V

P3-4 P1-2 WATER DISPENSING VALVE. SERVICE TEST 25. DIGIT 2 = 1 = 115 V

P3-5 P1-1 LEFT RC DOOR MUST BE CLOSED = 115 V. OPEN = 0 V

P3-6 P1-2 PANTRY HEATER OUTPUT, SERVICE TEST 73 19, 01 = 115 V, 02 = 0 V

P3-7 P3-8 130 VDC AUGER OUTPUT. LH RC DOOR CLOSED, ACTIVATE ICE PADDLE =

130 - 140 VDC

P4 P4-3 COMMUNICATION

P5

P5-1 P5-2 5 VDC RC THERMISTOR OUTPUT = 1.5 - 5 VDC. MAXIMUM

P5-3 P5-4 FC THERMISTOR OUTPUT = 1.5 - 5 VDC. MAXIMUM

P6 P6-1 P6-2 12.7 VDC CONSTANT 12.7 VDC

P7

P7-1 P7-2 5 VDC IM THERMISTOR OUTPUT = 1.5 - 5 VDC. MAXIMUM

P7-3 P7-4 12.7 VDC IM SWITCH

P7-5 P7-6 12.7 VDC IM MOTOR OUTPUT TEST 57, SW3 TO ACTIVATE. UP TO 2 MIN.

DELAY

P8

P8-1 P8-2 5 VDC FC DEFROST THERMISTOR OUTPUT= 1.5 - 5 VDC MAXIMUM

P8-5 ICE BOX FAN PWM CONNECTION

P8-3 P8-4 5 VDC RC EVAP THERMISTOR OUTPUT = 1.5 - 5 VDC MAXIMUM

P8-7 P8-8 3-6 VDC INVERTER OUTPUT 3-6 VDC CONSTANT WHEN COMPRESSOR IS

RUNNING

P9 P9-2 P9-3 12 VDC ICE BOX FASCIA HEATER OUTPUT

P12 P12-6 P1-2 IM HEATER OUTPUT TEST 58. WHEN DIGIT 1 = 1 HEATER ON (115 V)

P13

P13-1 P13-2 3 WAY REFRIGERANT VALVE, CAN NOT CHECK VOLTAGE OUTPUT

P13-3 P13-4 3 WAY REFRIGERANT VALVE, CAN NOT CHECK VOLTAGE OUTPUT

P13-5 5 VDC ICE BOX SENSOR

P14

P14-1 P14-2 14 VDC FC FAN MOTOR. OUTPUT ACTIVE SERVICE TEST 3, STEP 2

P14-3 P14-4 RC FAN MOTOR. OUTPUT ACTIVE SERVICE TEST 3, STEP 3

P14-7 P14-6 CONSTANT 14 VDC

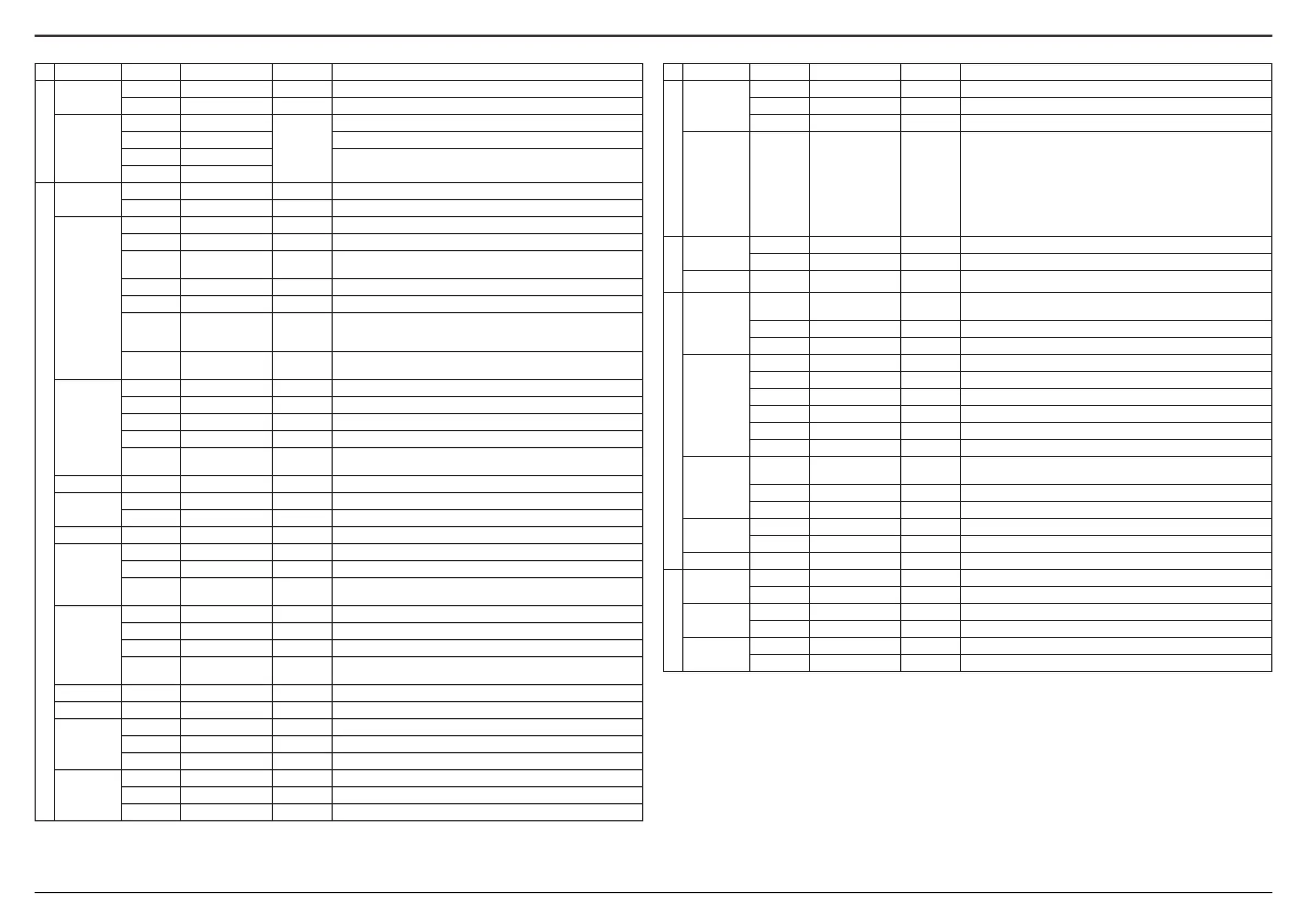

CONNECTOR FROM TO VOLTAGE CONDITIONS

EMITTER/RECEIVER

J1

J1-1 J1-3 14 VDC CONSTANT 14 VDC

J1-2 COMMUNICATION

J1-5

REFER TO

SERVICE

TEST

15 FOR

VERIFYING

THE

EMITTER/

RECEIVER

BOARDS

PANTRY UI

J1A

J1A-4 J1A-1 14 VDC CONSTANT 14 VDC

J1A-2 COMMUNICATION

J3A

J3-2 J3-4 5 VDC PANTRY THERMISTOR OUTPUT = 1.5 - 5 VDC MAXIMUM

DISPENSER BOARD

J1

J1-1 J1-2 14 VDC * 0 VDC WHEN ICE DISPENSER PAD IS PRESSED, 14 VDC WHEN

RELEASED

J1-1 J1-3 * ICE DISPENSER BUTTON IS PRESSED, (IF J1-3 USED)

J1-2 J1-3 * ICE DISPENSER PAD IS PRESSED, (IF J1-3 USED)

J2

J2-1 J2-8 14 VDC FLIPPER MULLION HEATER IN ON

J2-4 J2-6 14 VDC CONSTANT 14 VDC

J2-7 J2-11 14 VDC * ICE DOOR STEPPER MOTOR IS ACTIVE

J2-7 J2-12 * ICE DOOR STEPPER MOTOR IS ACTIVE

J2-7 J2-13 * ICE DOOR STEPPER MOTOR IS ACTIVE

J2-7 J2-14 * ICE DOOR STEPPER MOTOR IS ACTIVE

J3

J3-1 J3-2 14 VDC * 0 VDC WHEN ICE DISPENSER PAD IS PRESSED, 14 VDC WHEN

RELEASED

J3-1 J3-3 * WATER DISPENSER BUTTON IS PRESSED (IF J3-3 USED)

J3-2 J3-3 * WATER DISPENSER PAD IS PRESSED (IF J3-3 USED)

J5

J5-1 J5-3 14 VDC CONSTANT 14 VDC

J5-2 COMMUNICATION

J6 J6-1 J6-3 14 VDC DISPENSER LIGHT ON

AURORA

P1

P1-1 P1-4 CONSTANT 12.7 VDC

P1-3 COMMUNICATION

P2

P2-1 P2-2 SHELF LIGHTING OUTPUT

P2-3 P2-4 FILL TUBE HEATER FREEZER FC IM, FILL TUBE HEATER RC IM OUTPUT

P3

P3-1 P3-2 CAVITY LIGHT (POINT LED'S) OUTPUT

P3-3 P3-4 CAVITY LIGHT (POINT LED'S) OUTPUT

Loading...

Loading...