49WIKA operating instructions pressure transmitter, model IS-3

MM/YYYY country code based on 14095850.02 12/2014 EN/CN

EN

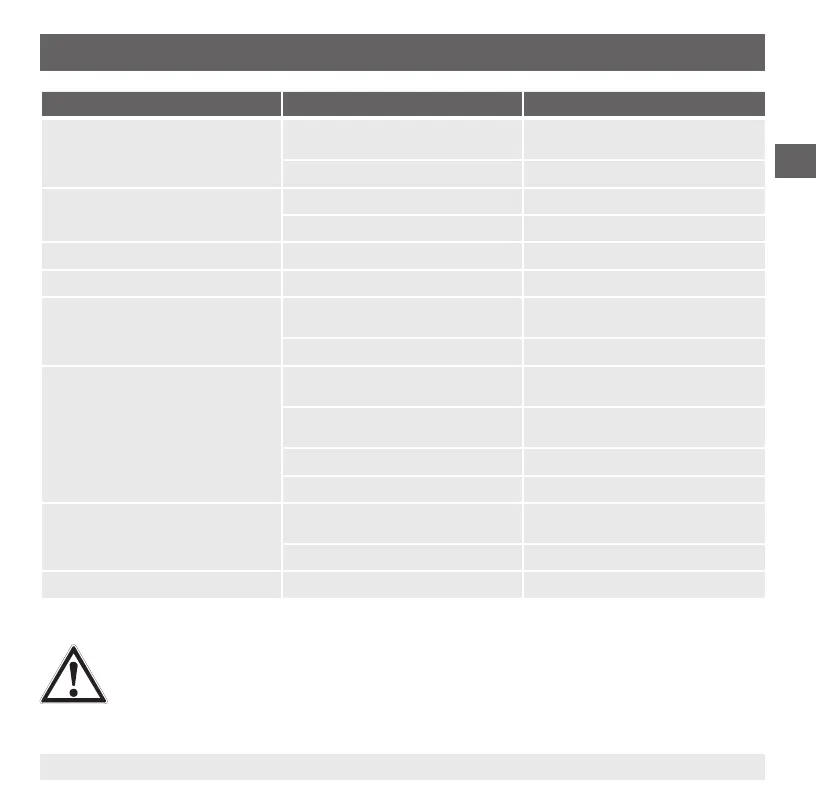

Faults Causes Measures

Constant output signal upon change in

pressure

Mechanical overload caused by overpres-

sure

Replace instrument; if it fails repeatedly,

contact the manufacturer

Wrong power supply or current pulse Replace instrument

No output signal No or wrong power supply, current pulse Rectify the power supply

Cable break Check the connection cables for continuity

No or wrong output signal Wiring error Rectify the wiring

Deviating output signal Span maladjusted Readjust span and use suitable reference

1)

Deviating zero point signal Overpressure limit exceeded Readjust zero point

1)

Observe overpressure limit

Damage at the process connection Replace instrument

Signal span drops Damage at the process connection Replace instrument; if it fails repeatedly,

contact the manufacturer

Sealing is damaged or soiled If soiled, clean the sealing and the measur-

ing point. If damaged, replace the sealing.

Sealing does not have a tight t Remove the instrument and seal correctly

Threads jammed Mount the instrument correctly

Signal span too small Mechanical overload caused by overpres-

sure

Readjust the instrument

1)

Wrong power supply Rectify the power supply

Signal span varies Strongly varying pressure of the medium Damping; consulting by the manufacturer

1) After the adjustment, check that the system is functioning correctly. If the error still persists, replace the instrument or send it for repair (see chapter 10.2 “Return”).

CAUTION!

If faults cannot be eliminated by means of the measures listed above, shut down the instrument immedi-

ately, and ensure that pressure and/or signal are no longer present, and secure the instrument from

being put back into operation inadvertently. In this case, contact the manufacturer. If a return is needed,

follow the instructions given in chapter 10.2 “Return”.

9. Faults

Loading...

Loading...