WIKA operating instructions models PGS10, PGS11 and PGS21

13

Requirements for the installation point

If the measuring point is not adequately stable a measuring instrument

support such as a bracket or ange should be used for fastening (and

possibly via a exible capillary line). If the pressure gauge is exposed to

vibration or pulsating pressure or both, then a liquid lled pressure gauge

may provide considerably better performance and readability. Instruments

should be protected against coarse dirt and wide uctuations in ambient

temperature.

Installation

Nominal position per EN 837-1 / 9.6.7 Figure 9: 90° ( ⊥ )

Process connection bottom or rear!

In order to avoid any additional heating, the instruments must not be

exposed to direct solar irradiation while in operation!

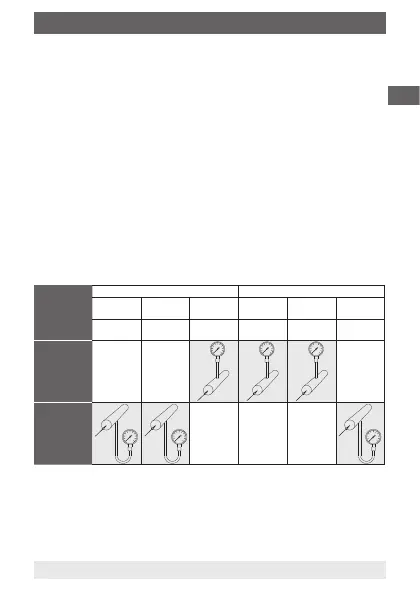

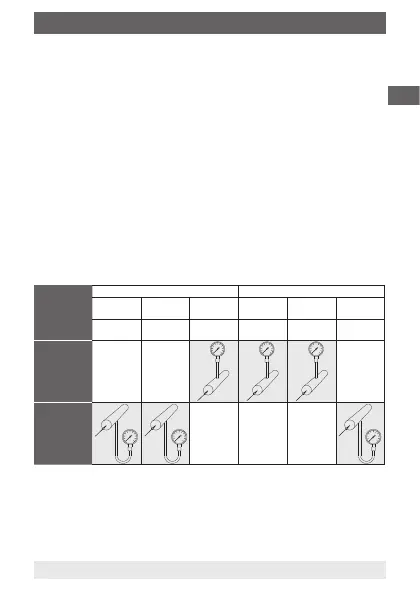

Measuring assemblies

Proven measuring assemblies for various types of media.

7. Commissioning, operation

Admissible ambient and working temperatures

When mounting the pressure gauge it must be ensured that, taking into

consideration the inuence of convection and heat radiation, no deviation

above or below the permissible ambient and medium temperatures can

occur. The inuence of temperature on the display accuracy must be

observed.

liquid media gaseous media

Filling of the

capillary

liquid

liquid with

vapour

vapour only gaseous wet gas

liquid gas

condensate

Examples

condensate boiling liquid

"liqueed

gases"

dry air

moist air, ue

gases

Steam

Pressure

gauge above

the tapping

point

Pressure

gauge below

the tapping

point

11581752.01 07/2010 GB/D/F/E

GB

Loading...

Loading...