l

l

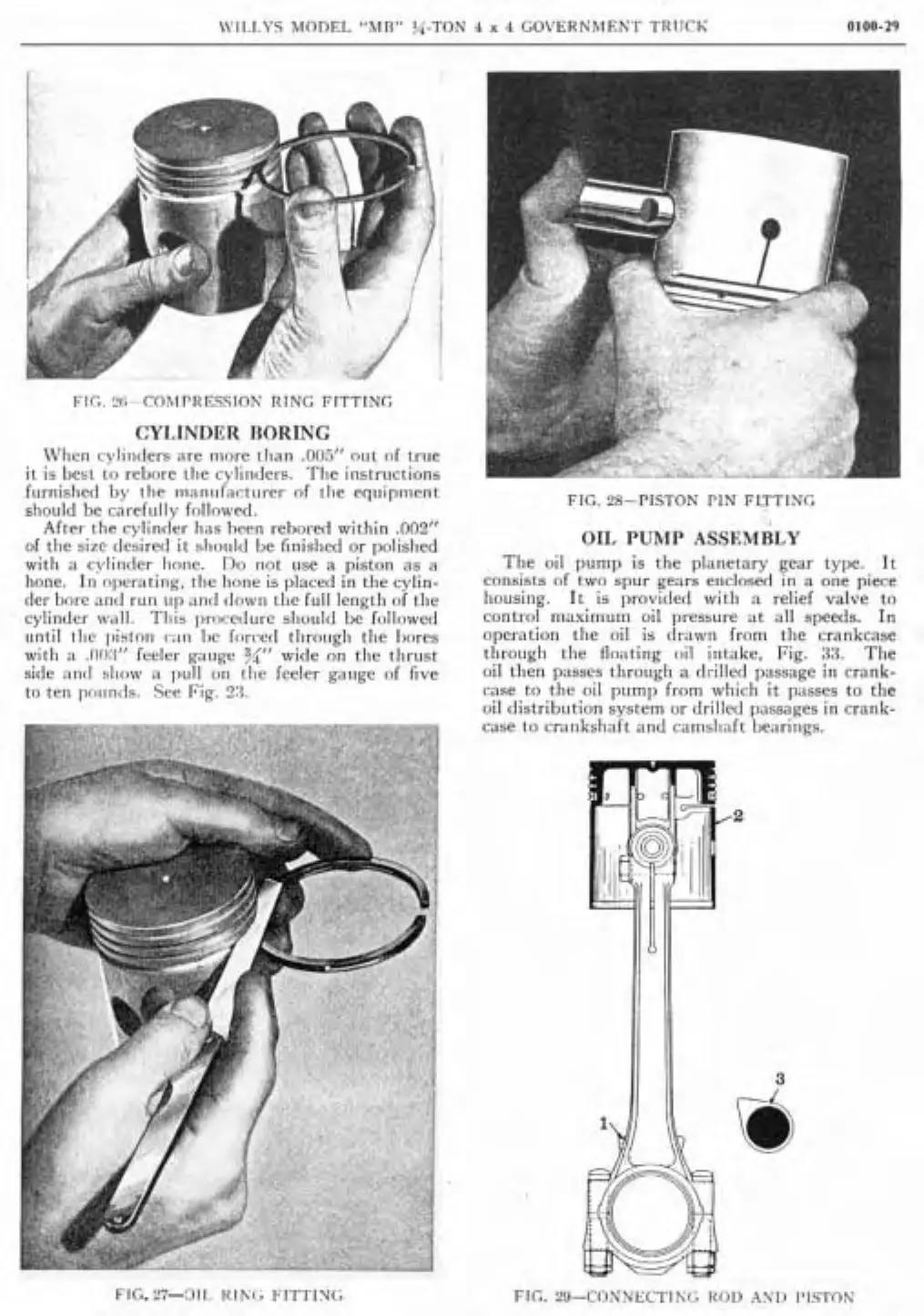

COA1PRESSIOh'

RING

FITTING

CY1,INDER

BORING

When cyliiiders are iiiore tlian

.OOC>"

out of triie

it is best to rebore tlie cyliiiclers. Tlie instriictions

furnislied by tlie maniifacturer of tlie eqiiipnient

should

be carefiilly followed.

After the cylinder lias heen rehored within

,002''

of the size desired it slioiild be finished or polistied

witli a csliiider Iioiie. Do iiot use a piston as a

hone. In

nperating, the Iione

is

placed in the cylin-

der bore anrl ruil iip anrl down tlie full lengtti of tlie

cylincler wall. Tliis procedure should be followed

iintil tlie pislnri r:nii

I)c

fnrcecl tliroiigli tlie hores

with a

.00:3"

feeler gauge

x"

wide on tlie tlirust

side

nriil

sliow a

11~111

on

tlie feeler gaitge of Tive

to ten poiitids. See Fig.

23.

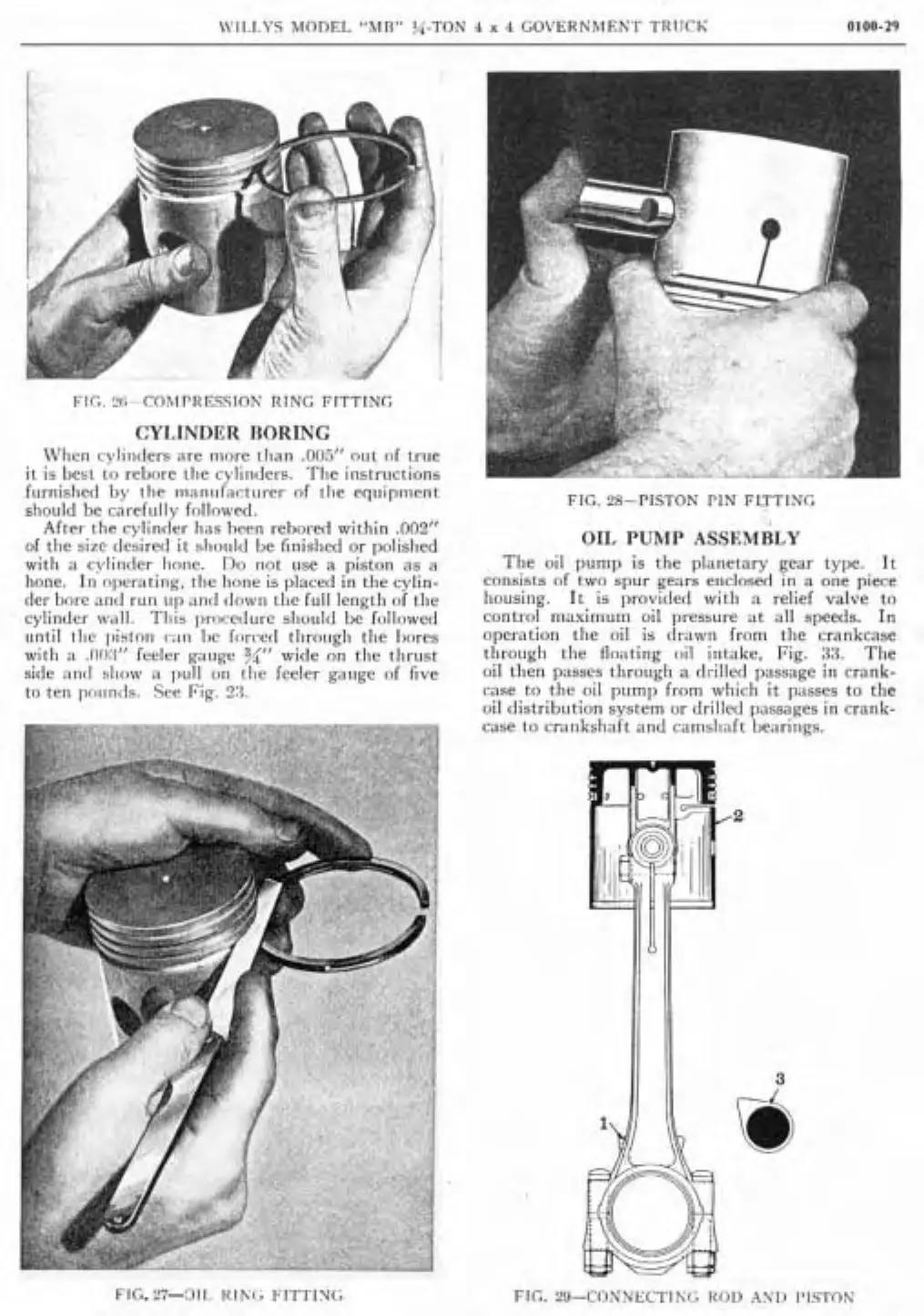

FIG.

28-PISTON

PIN

FLTTING

OIL

PUMP

ASSEMBLY

The oil pump is the planetary gear type.

It

consists of two spur gears eiiclosed in

a

olie piece

tiousing.

It

is provided with a relief valoe to

control maximum oil pressure at al1 speeds. In

operation the oil is drawn from the crankcase

tliroitgh tlie floating »i1 intake, Fig.

33.

Tlie

oil then passes through a drilled passage in crank-

case to tlie oil pump from

wliich it p;isses to the

oil distribution system ar drilled passages in crank-

case to

cranlcshaft and camsliaft bearirigs.

FIG.

29-CONNECTIKG

Rol>

ANI)

I'ISTON

Loading...

Loading...