English

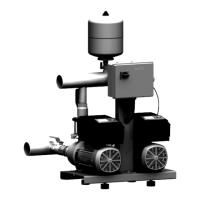

Installation and operating instructions Wilo-COR..MHIE.../MS 11

8 Commissioning/decommissioning

We recommend that you arrange for initial com

-

missioning of your pressure-boosting system to

be conducted by your closest Wilo customer ser

-

vice agent or simply contact Wilo central customer

service.

8.1 General preparations and control measures

• Prior to initial commissioning, check the wiring

installed by the customer, in particular the earth

connection;

• Check the source of the water supply (sufficiently

full replenishment reservoir or appropriate munic

-

ipal water supply);

• Fill the system and ensure its impermeability by

conducting a visual inspection;

• Open the gate valves on the pumps and in the

suction and discharge pipes;

• Open the stoppers in the pumps’ ventilation sys

-

tem and slowly fill the pumps with water so as to

allow the air to escape entirely.

CAUTION! Risk of damage to the installation!

Never let the pump run dry. Dry running

destroys the mechanical seal and causes the

motor to overload.

• Pressurise the diaphragm pressure vessel. The

vessel’s inflating pressure must be 0.3 bar below

the pressure that activates the pumps.

DANGER!

Do not exceed the tank’s maximum

pre-inflation value.

• Check the pumps’ direction of rotation: on a short

start-up, check whether the pumps’ direction of

rotation corresponds to the arrow situated on the

pump housing. If the direction of rotation is incor

-

rect, swap two phases.

DANGER! Risk of electrical shock!

Before swapping the phases, cut the power sup

-

ply using the system’s main on/off switch.

• On the switchgear, check and adjust the required

service parameters in accordance with the instal

-

lation and operating instructions supplied.

8.2 Commissioning the system

After completing all preparatory work and per

-

forming all checks detailed in Section 8.1, engage

the main on/off switch.

The pressure sensor measures the available pres

-

sure and sends the corresponding electronic sig

-

nal to the control device.

If the pressure is lower than the set start-up pres

-

sure, this activates the primary pump according to

the set parameters and control type and possibly

the peak-load pump(s) until the consumer’s pipe

network is filled with water and the adjusted pres

-

sure is reached.

Adjustment

Set the card’s adjustable resistor using a screw

-

driver (Fig. 3, pos. 4) to obtain the desired pres

-

sure level (read the settings on the variators’

displays).

NOTE:

Offsetting of the set point values by around 5%

between each variator is completely normal.

CAUTION!

Do not allow the pump to operate for more than

one minute with the discharge valve closed.

8.3 Decommissioning the system

If the pressure-boosting system must be decom

-

missioned to allow for maintenance and repair

work or the like to be completed, proceed as

follows:

• Switch off the main on/off switch and ensure that

the system cannot be reactivated by unauthorised

persons.

• Close the gate valves before and after installation.

• Isolate and drain the diaphragm pressure vessel.

• If necessary, drain the system entirely.

9 Maintenance

Maintenance and repair work must only be carried

out by qualified personnel!

DANGER! Risk of fatal injury!

In case of work on electrical devices, there is a

danger of death by electrocution.

Before performing any maintenance or repair

work, disconnect the device or system from the

power supply and make sure it cannot be reacti

-

vated by unauthorised persons. In general, only

a qualified electrician/engineer should be

allowed to repair damaged connecting cables.

To ensure optimal operational reliability and to

keep operating costs at a minimum, it is advisable

to conduct inspections and maintenance of the

pressure-boosting system on a regular basis (refer

to standard DIN 1988). To do so, the best solution

is to subcontract maintenance work to a specialist

firm or our customer service.

The following inspections must be conducted on a

regular basis:

• Check that the pressure-boosting system is in

good working order.

• Check the pumps’ mechanical seals. The mechan

-

ical seals use water for lubrication, small quanti

-

ties of which may therefore leak from the gasket.

In case of more substantial leakage, the mechani

-

cal seal must be replaced.

•

Check (ideally every 3 months) that the diaphragm

pressure vessel is kept at the correct pressure for

initial compressing and that it is impermeable.

Loading...

Loading...