15

same time, installation should be

carried out such that any leaking

water cannot drop onto the control

module, align upper slide valve

laterally.

– Carry out off-load installation

with the pump motor lying hori-

zontally. Mounting positions for

the module see fig. 3. Other

mounting positions on request.

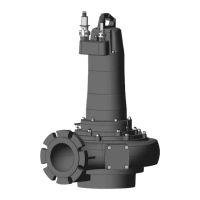

– An arrow on the pump casing

indicates the direction of flow

(fig. 4, Pos.1).

– When screwing the pump into the

pipework the pump can be secu-

red with a spanner against turning

at the appropriate points (fig. 5).

– If the mounting position of the

module is to be changed, the

motor casing must be rotated as

follows:

– Unscrew 2 Allen screws on

pump casing,

– Rotate motor casing, including

control module,

Be careful

not to dama-

ge the seal. Seal size:

l 86x l 76 x 2.0 mm EP

– Tighten Allen screws,

– For units which

are to be insu-

lated, only the pump housing may

be insulated. The motor and the

condensation water holes must

remain free from all blockages (Fig.

4, pos.2).

ATTENTION!

ATTENTION!

ENGLISH

– Setting (fig. 1, pos. 2)

auto = automatic operation

„ON“

= automatic operation

„OFF“

– Setting range (fig.2):

E... / 1 - 3: H

min

= 0.5 m,

H

max

= 3.0 m.

E... / 1 - 5: H

min

= 1.0 m,

H

max

= 5.0 m.

4.2 Products delivered

– Heat circulating pump complete,

– Installation and operating

instructions

5 Assembly/Installation

5.1 Assembly

– The pump should only be instal-

led once all welding and solde-

ring work is complete and the

pipework has if necessary been

thoroughly flushed.

– Install the pump in an easily

accessible place, so it can easily

be inspected or replaced.

– When installing flow pipes in open

units, the expansion flow pipe

must branch off before the pump.

– Shut-off valves should be fitted

before and after the pump to

facilitate replacement. At the

Loading...

Loading...