Installation and electrical connection en

Installation and operating instructions Wilo Motor T 17.3, 20.2:, EMU FA, Rexa SUPRA, Rexa SOLID 67

6.4.1 Indications for double pump oper-

ation

If several pumps are used in an operating space, minimum distances between the

pumps and the wall must be complied with. Here there is a difference in the distances

depending on the type of system: Alternating operation or parallel operation.

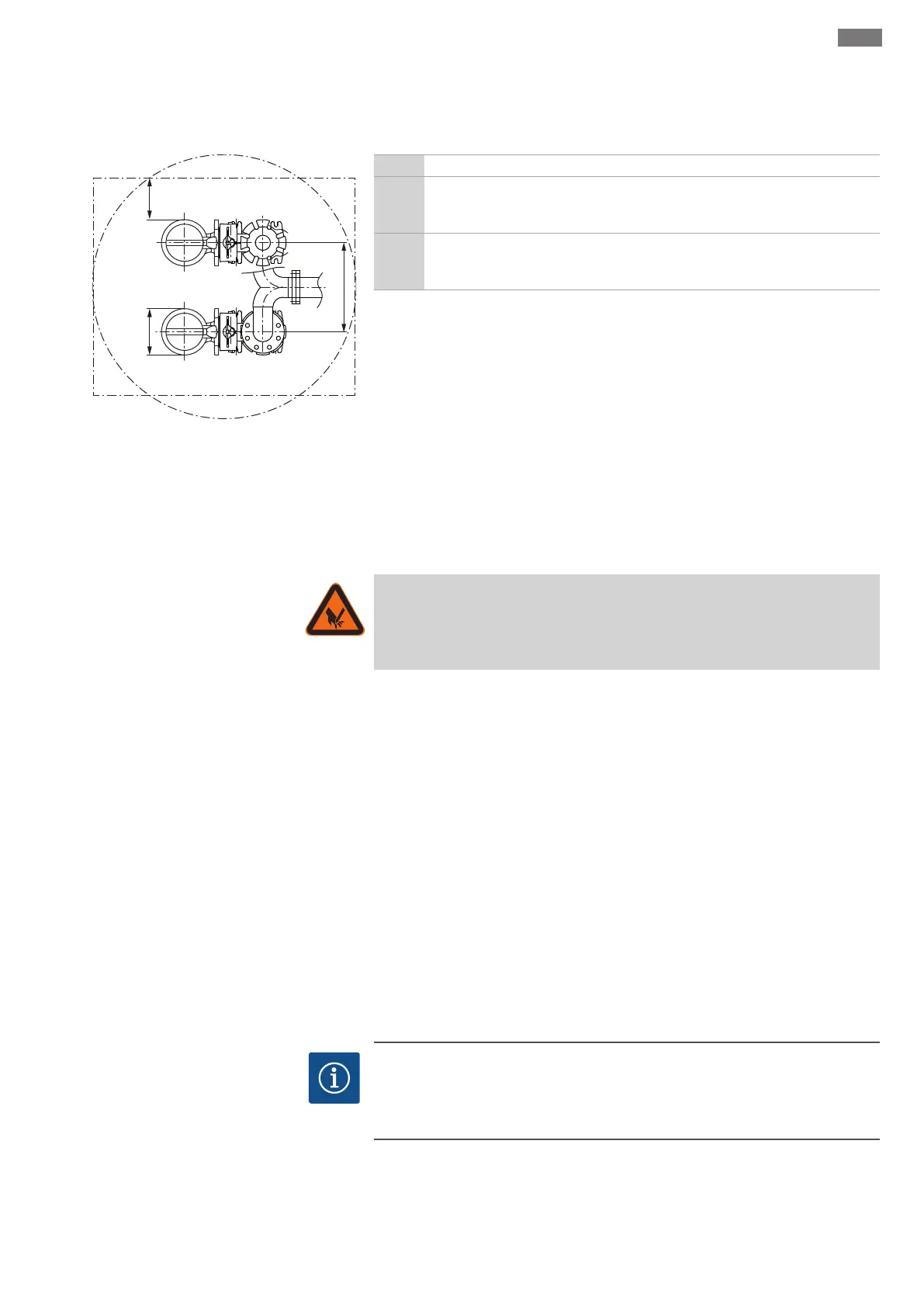

Fig.3: Minimum distances

d Diameter hydraulics housing

A

1

Minimum distance from the wall:

- alternating operation: min. 0.3×d

- parallel operation: min. 1×d

A

2

Distance to pressure pipes

- alternating operation: min. 1.5×d

- parallel operation: min. 2×d

6.4.2 Maintenance tasks

After a storage period of more than 6months, carry out the following maintenance

tasks before installation:

ƒ Rotate the impeller.

ƒ Check the oil in the sealing chamber.

6.4.2.1 Rotate impeller

WARNING

Sharp edges on the impeller and suction port!

Sharp edges can form on the impeller and suction port. There is danger of limbs be-

ing severed! Protective gloves must be worn to protect from cuts.

Small pumps (up to DN100 pressure port)

‡ The pump is not connected to the mains!

‡ Use protective equipment!

1. Place the pump on a firm surface in a horizontal position. WARNING!Risk of hands

being crushed. Make sure that the pump cannot fall over or slip!

2. Slowly and carefully reach into the hydraulics housing from below and rotate the

impeller.

Large pumps (from DN150 pressure port)

‡ The pump is not connected to the mains!

‡ Use protective equipment!

1. Place the pump upright on a firm surface. WARNING!Risk of hands being crushed.

Make sure that the pump cannot fall over or slip!

2. Carefully and slowly reach into the hydraulics housing through the pressure port

and rotate the impeller.

6.4.2.2 Check oil in the sealing chamber

NOTICE

Slightly tilt the motor to fill the oil!

Slightly tilt the sealing chamber to completely fill it with oil. Secure the motor

against falling over and slipping during the filling process!

Loading...

Loading...