en Installation and electrical connection

68 WILO SE 2019-10

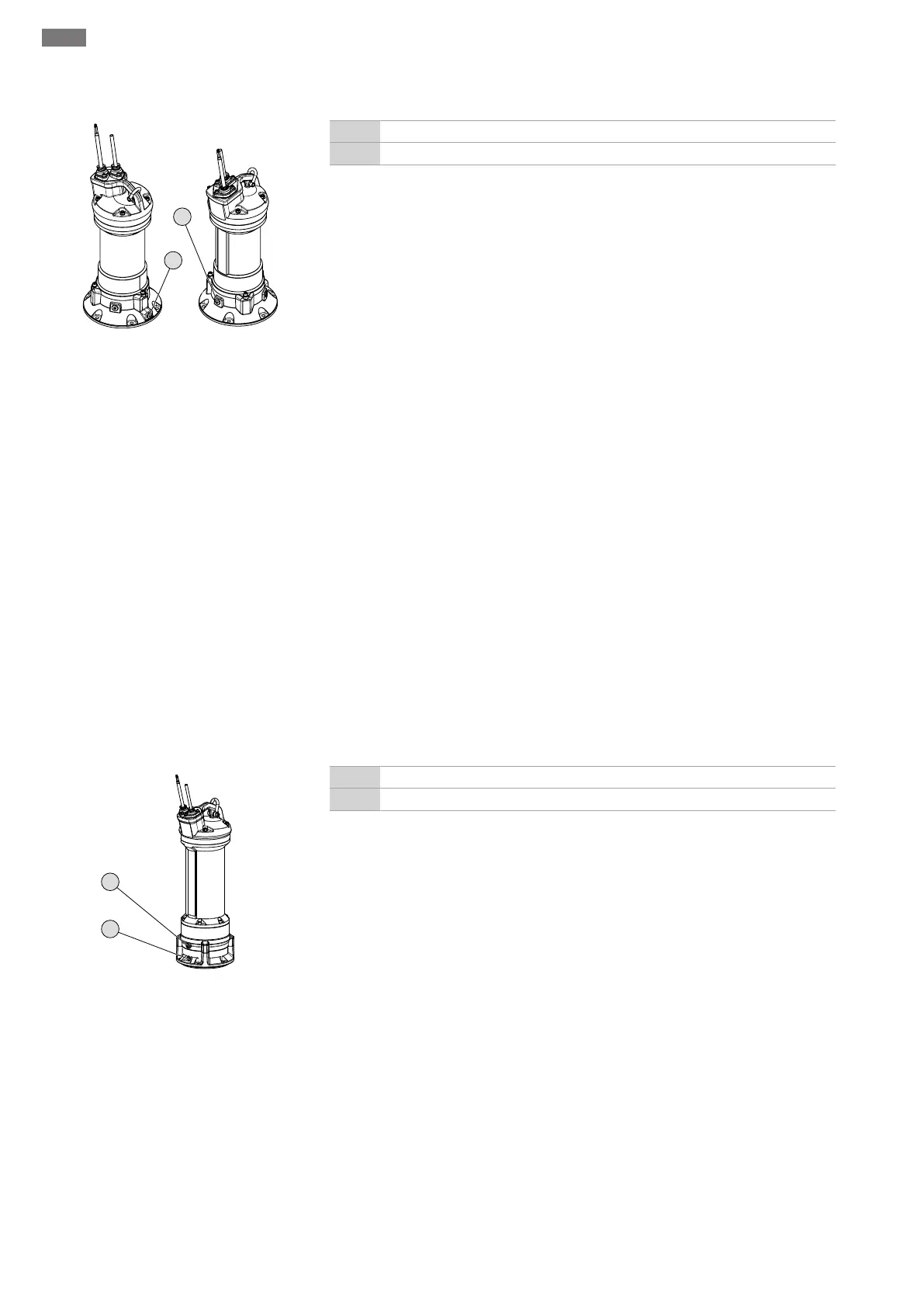

Motor T17.3...-P (permanent magnet motor)

Fig.4: Sealing chamber: Check the oil

+ Add the oil to the sealing chamber

- Drain the oil from the sealing chamber

‡ Pump is not installed.

‡ Pump is not connected to the mains.

‡ Use protective equipment!

1. Place the pump upright on a firm surface.WARNING!Risk of hands being crushed.

Make sure that the pump can not fall over or slip!

2. Position a suitable reservoir to collect the operating fluid.

3. Unscrew the screw plug (+).

4. Unscrew the screw plug (-) and drain the operating fluid. Open the ball valve if a

ball valve has been installed at the outlet opening.

NOTICE!Vacuum the oil or rinse the sealing chamber to fully drain the system.

5. Check the operating fluid:

⇒ If the operating fluid is clear, reuse the operating fluid.

⇒ If the operating fluid is contaminated (black), fill with new operating fluid. Dis-

pose of the operating fluid in accordance with local regulations!

⇒ If there is water in the operating fluid, fill with new operating fluid. Dispose of

the operating fluid in accordance with local regulations!

⇒ Notify customer service if the operating fluid contains metal swarf!

6. If a ball valve is installed on the outlet opening, close the ball valve.

7. Clean the screw plug (-), replace the seal ring and screw it back in. Max. tightening

torque: 8Nm (5.9ft·lb)!

8. Pour new operating fluid in through the hole for the screw plug (+).

⇒ Comply with the specifications for the operating fluid type and quantity!

When recycling the operating fluid, check the quantity and adjust it, if re-

quired!

9. Clean the screw plug (+), replace the seal ring and screw it back in. Max. tightening

torque: 8Nm (5.9ft·lb)!

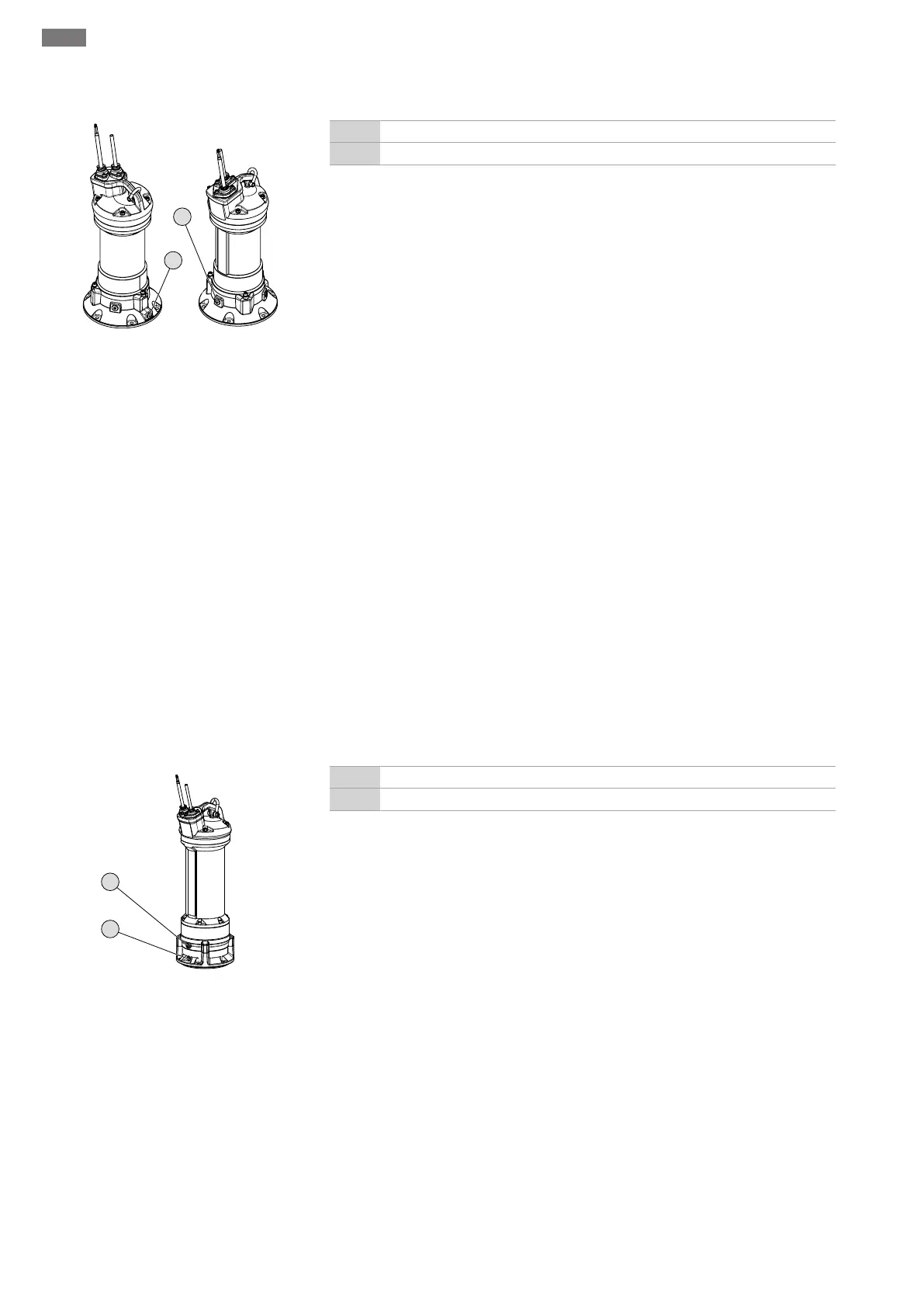

Motor T20.2 (asynchronous and permanent magnet motor)

Fig.5: Sealing chamber: Check the oil

+ Add the oil to the sealing chamber

- Drain the oil from the sealing chamber

‡ Pump is not installed.

‡ Pump is not connected to the mains.

‡ Use protective equipment!

1. Place the pump upright on a firm surface.WARNING!Risk of hands being crushed.

Make sure that the pump can not fall over or slip!

2. Position a suitable reservoir to collect the operating fluid.

3. Unscrew the screw plug (+).

4. Unscrew the screw plug (-) and drain the operating fluid. Open the ball valve if a

ball valve has been installed at the outlet opening.

NOTICE!Vacuum the oil or rinse the sealing chamber to fully drain the system.

5. Check the operating fluid:

⇒ If the operating fluid is clear, reuse the operating fluid.

⇒ If the operating fluid is contaminated (black), fill with new operating fluid. Dis-

pose of the operating fluid in accordance with local regulations!

⇒ If there is water in the operating fluid, fill with new operating fluid. Dispose of

the operating fluid in accordance with local regulations!

⇒ Notify customer service if the operating fluid contains metal swarf!

6. If a ball valve is installed on the outlet opening, close the ball valve.

Loading...

Loading...