en Installation and electrical connection

74 WILO SE 2019-10

Description

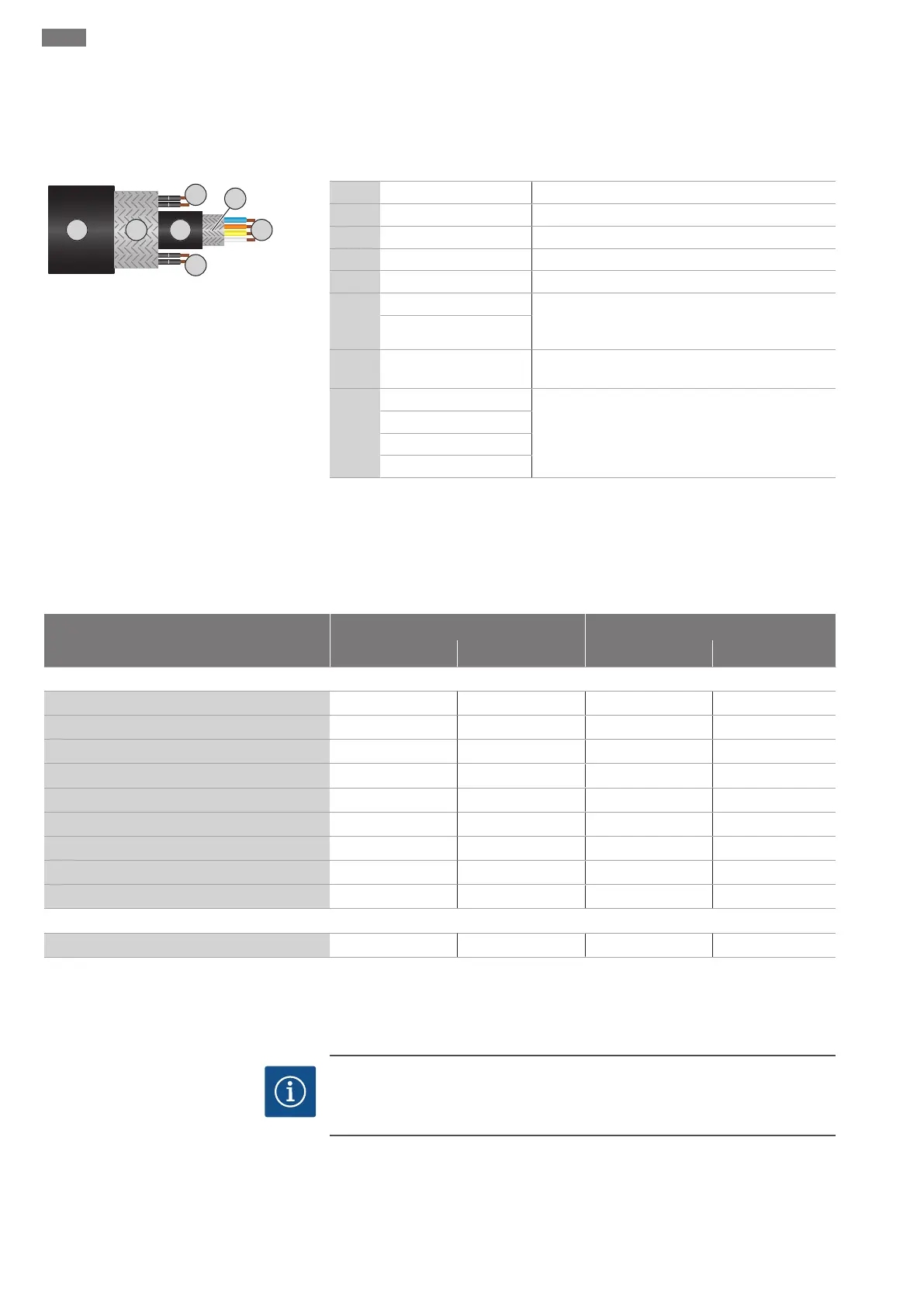

A hybrid cable is used as the control cable. The hybrid cable merges two cables in one:

ƒ Signal cable for control voltage and winding monitor

ƒ Network cable

Fig.10: Hybrid cable diagram

Pos. Wire no/colour Description

1 Outer cable sheath

2 Outer cable shielding

3 Inner cable sheath

4 Inner cable shielding

5

1 = + Connection wires for Digital Data Interface power

supply. Operating voltage: 24VDC (12-30V FELV,

max. 4.5W)

2 = -

6

3/4 = PTC PTC sensor connection wires in the motor winding.

Operating voltage: 2.5 to 7.5VDC

7

White (wh) = RD+ Prepare the network cable and install the supplied

RJ45 plug.

Yellow (ye) = TD+

Orange (og) = TD-

Blue (bu) = RD-

The connection of the Digital Data Interface depends on the selected system mode and

other system components. Note installation suggestions and connection variants in the

instructions for the Digital Data Interface.

NOTICE!Widely position cable shielding!

6.5.6 Monitoring equipment connection

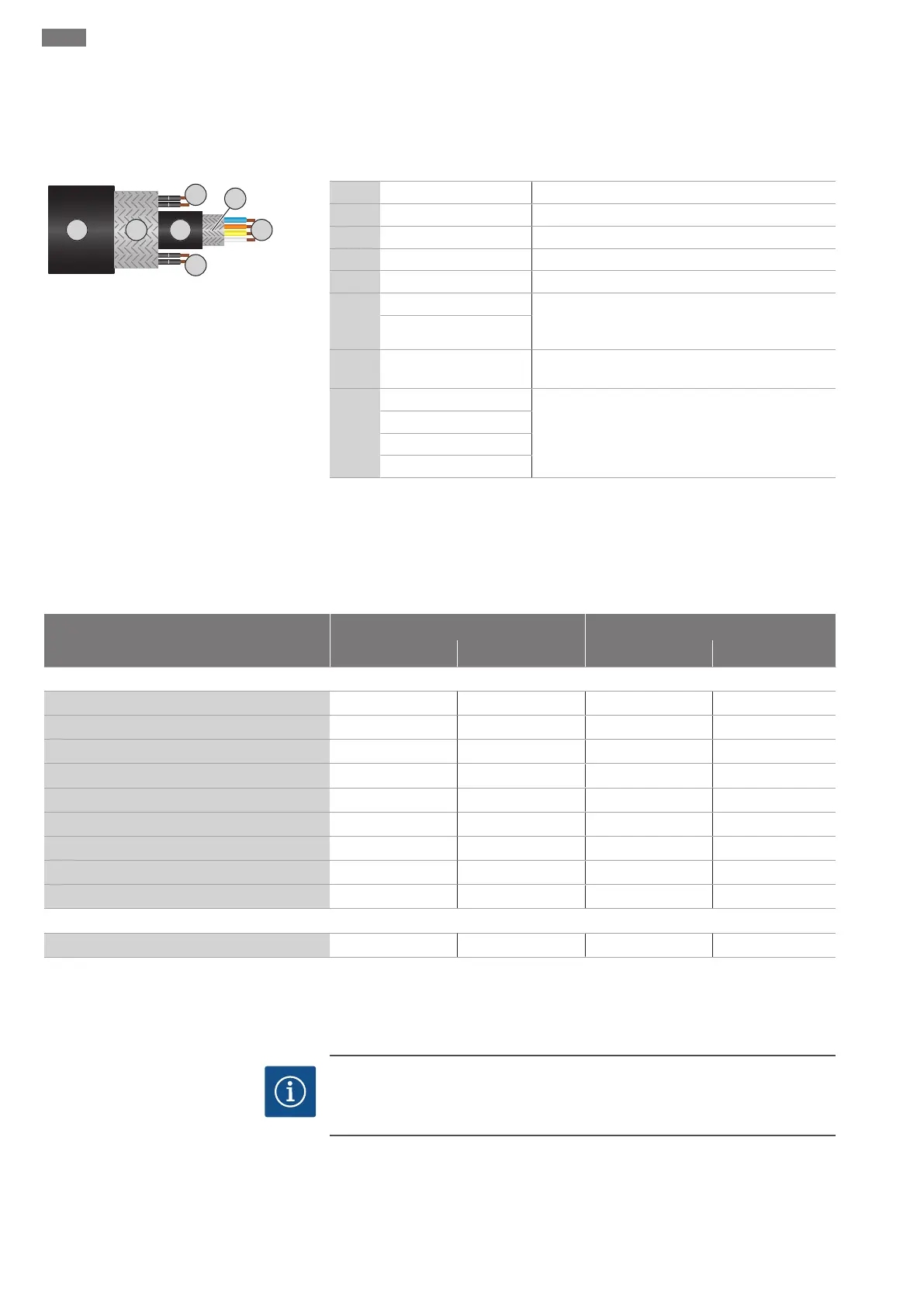

Overview of monitoring devices

Asynchronous motor Permanent magnet motor

T20.2 T20.2 T17.3...-P T20.2...-P

Internal monitoring devices

Digital Data Interface

− • • •

Motor winding: Bimetallic strip

• − − −

Motor winding: PTC

o • (+ 1...3x Pt100) • (+ 1...3x Pt100) • (+ 1...3x Pt100)

Motor bearings: Pt100

o o o o

Sealing chamber: conductive sensor

− − − −

Sealing chamber: capacitive sensor

− • • •

Leakage chamber: Float switch

• − − −

Leakage chamber: capacitive sensor

− • − •

Vibration sensor

− • • •

External monitoring devices

Sealing chamber: conductive sensor

o − − −

• = Standard, − = Not available, o = Optional

All the monitoring devices fitted must always be connected!

Motor with Digital Data Interface

NOTICE

Note the instructions for the Digital Data Interface!

Read the separate instructions for the Digital Data Interface and comply with them.

The Digital Data Interface evaluates all available sensors. Use the graphical user inter-

face of the Digital Data Interface to display current values and set the limit parameters.

A warning message or alarm signal is output upon exceeding the limit parameters. The

motor winding additionally features PTC sensors to enable secure pump deactivation.

Loading...

Loading...