en Maintenance and repair

32 WILO SE 2017-06

9 Maintenance and repair

DANGER

Danger due to fluids hazardous to health!

If the pump is used in fluids hazardous to health, decontaminate the pump after dis-

mantling and before carrying out any other work! There is danger to life! Observe the

specifications in the work regulations! The operator must make sure that the per-

sonnel has received and read the work regulations!

NOTICE

Only use lifting equipment in a technically sound condition!

Only use lifting equipment in a technically sound condition for lifting, lowering and

transporting the pump. Ensure that the pump does not become jammed during lift-

ing and lowering. Do not exceed the max. permissible bearing capacity of the lifting

equipment!

▪Always carry out maintenance tasks in a clean location with good lighting. It must be

possible to position the pump safely and secure it.

▪Only carry out maintenance tasks mentioned in this installation and operating instruc-

tions.

▪Wear the following protective equipment while performing maintenance tasks:

– Safety goggles

– Safety shoes

– Safety gloves

9.1 Personnel qualifications

▪Electrical work: Electrical work must be carried out by a qualified electrician (in accord-

ance with EN50110-1).

▪Maintenance tasks: The technician must be familiar with the use of operating fluids and

their disposal. In addition, the technician must have basic knowledge of mechanical en-

gineering.

9.2 Operator responsibilities

▪Provide the necessary protective equipment and make sure that the personnel wears it.

▪Collect operating fluids in suitable tanks and disposed of properly.

▪Dispose of protective clothing used in accordance with regulations.

▪Use only original parts of the manufacturer. Use of parts other than the original parts

releases the manufacturer from any liability.

▪Collect any leakage of fluid and operating fluid immediately and dispose of it according

to the locally applicable guidelines.

▪Provide the tools required.

▪If flammable solvents and cleaning agents are used, open flames, naked lights and

smoking are prohibited.

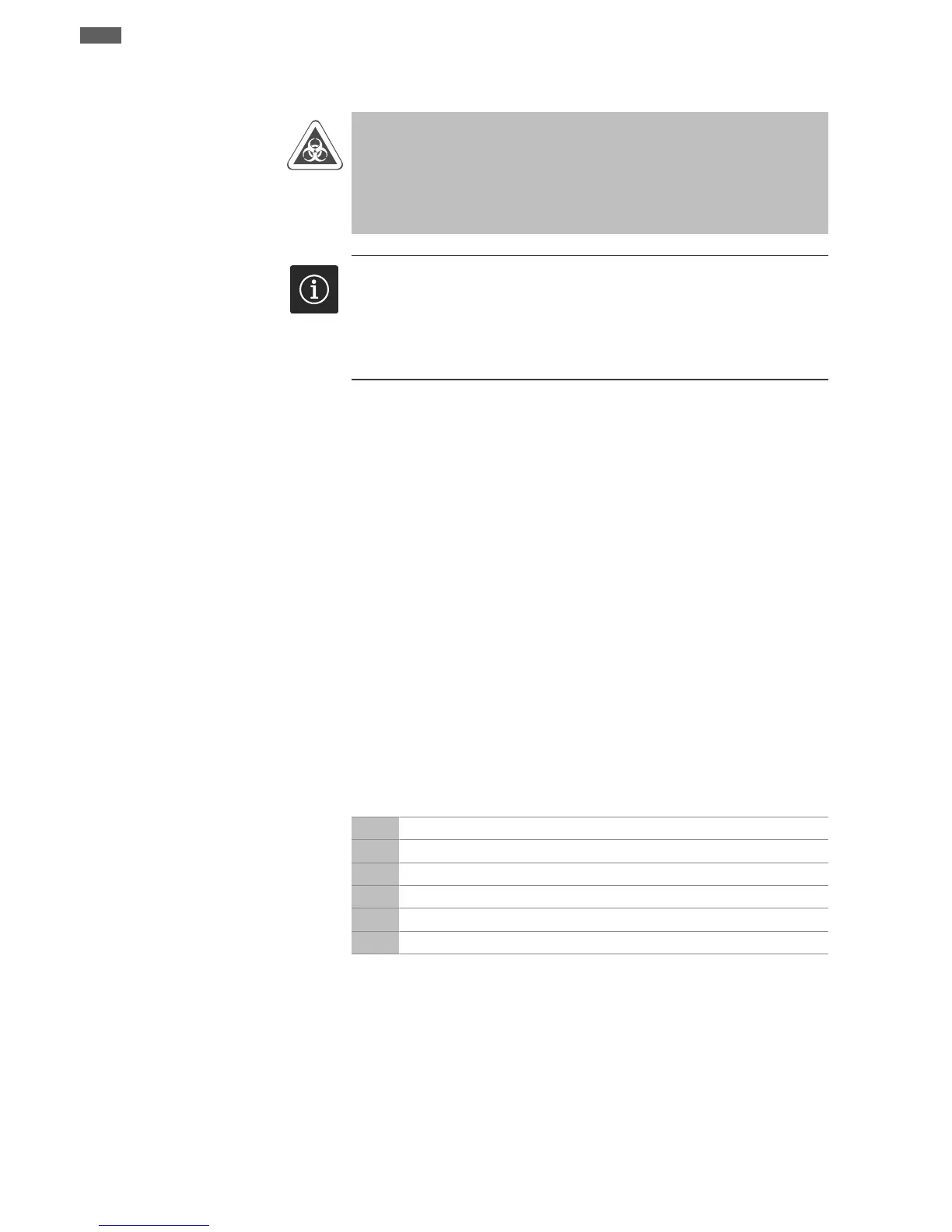

9.3 Labelling of the screw plugs

M

Motor compartment screw plugs

D

Sealing chamber screw plugs

K

Cooling system screw plugs

L

Leakage chamber screw plug

S

Condensation water chamber screw plug

F

Grease nipple screw plug

9.4 Operating fluid

9.4.1 Oil types

Biological white oil is filled-in into the sealing chamber. The following oil types are re-

commended when changing the oil:

▪Aral Autin PL*

▪Shell ONDINA 919

▪Esso MARCOL 52* or 82*

▪BP WHITEMORE WOM 14*

▪Texaco Pharmaceutical 30* or 40*

All oil types marked with “*” are approved for use with foods in accordance with

“USDA-H1”.

Loading...

Loading...