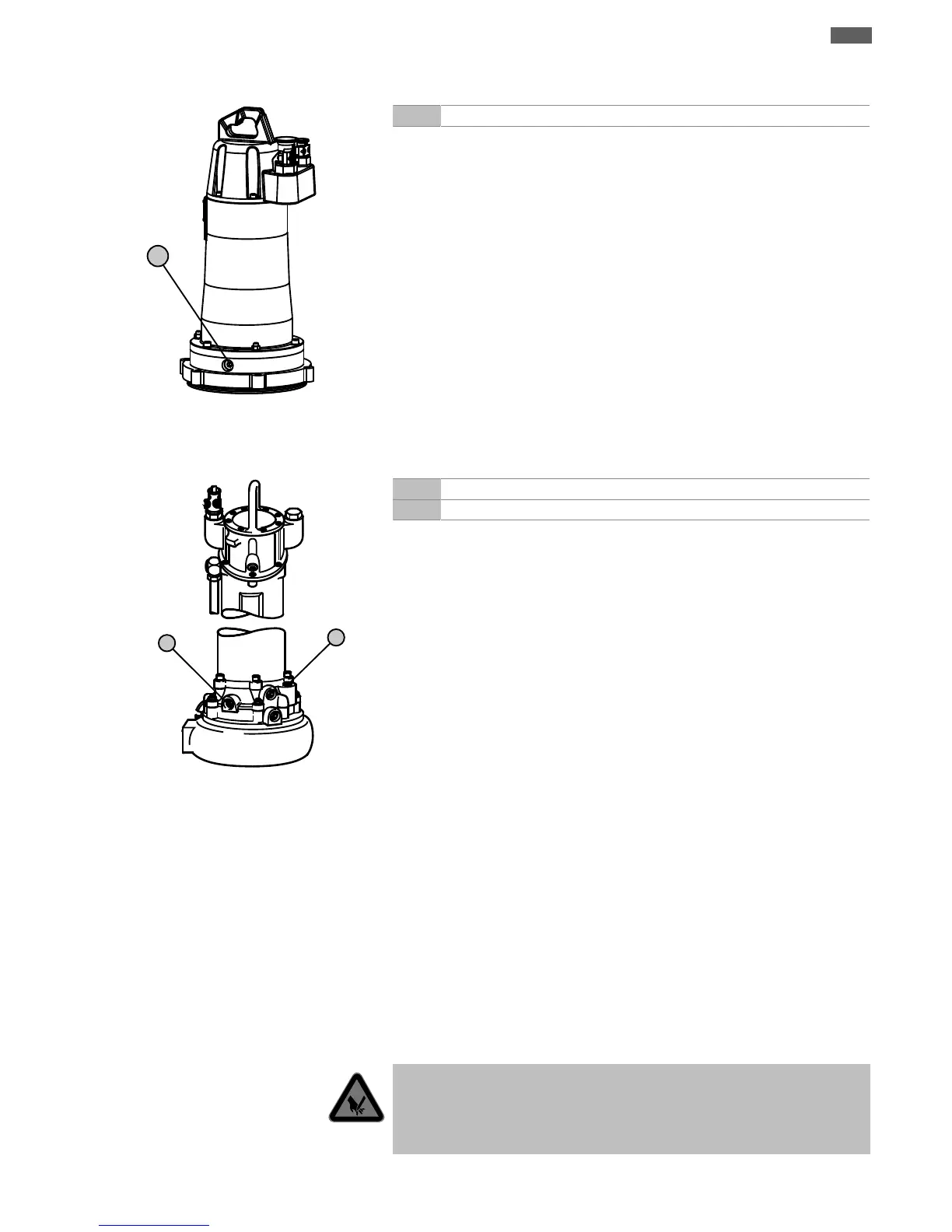

Fig.13: Sealing chamber: Oil change

+/- Fill/drain the oil in the sealing chamber

‡ Protective equipment has been put on!

‡ Pump has been dismantled and cleaned (decontaminated if required).

1. Place the pump upright on a firm surface.WARNING!Risk of hands being crushed.

Ensure that the pump cannot fall over or slip away!

2. Place a suitable tank to collect the operating fluid.

3. Unscrew the screw plug slowly, but do not unscrew it completely. WARN-

ING!Overpressure in the motor! Stop turning the screw plug further if hissing

or whistling is audible! Wait until the pressure has completely dissipated.

4. After the pressure has dissipated, fully unscrew the screw plug and drain the oper-

ating fluid.

5. Check the operating fluid: Notify customer service if an operating fluid contains

metal chips!

6. Pour the new operating fluid in through the opening.

⇒ Comply with the specifications for operating fluid locations and quantity!

7. Clean the screw plug, replace the seal ring and screw it back in. Max. tightening

torque: 8Nm!

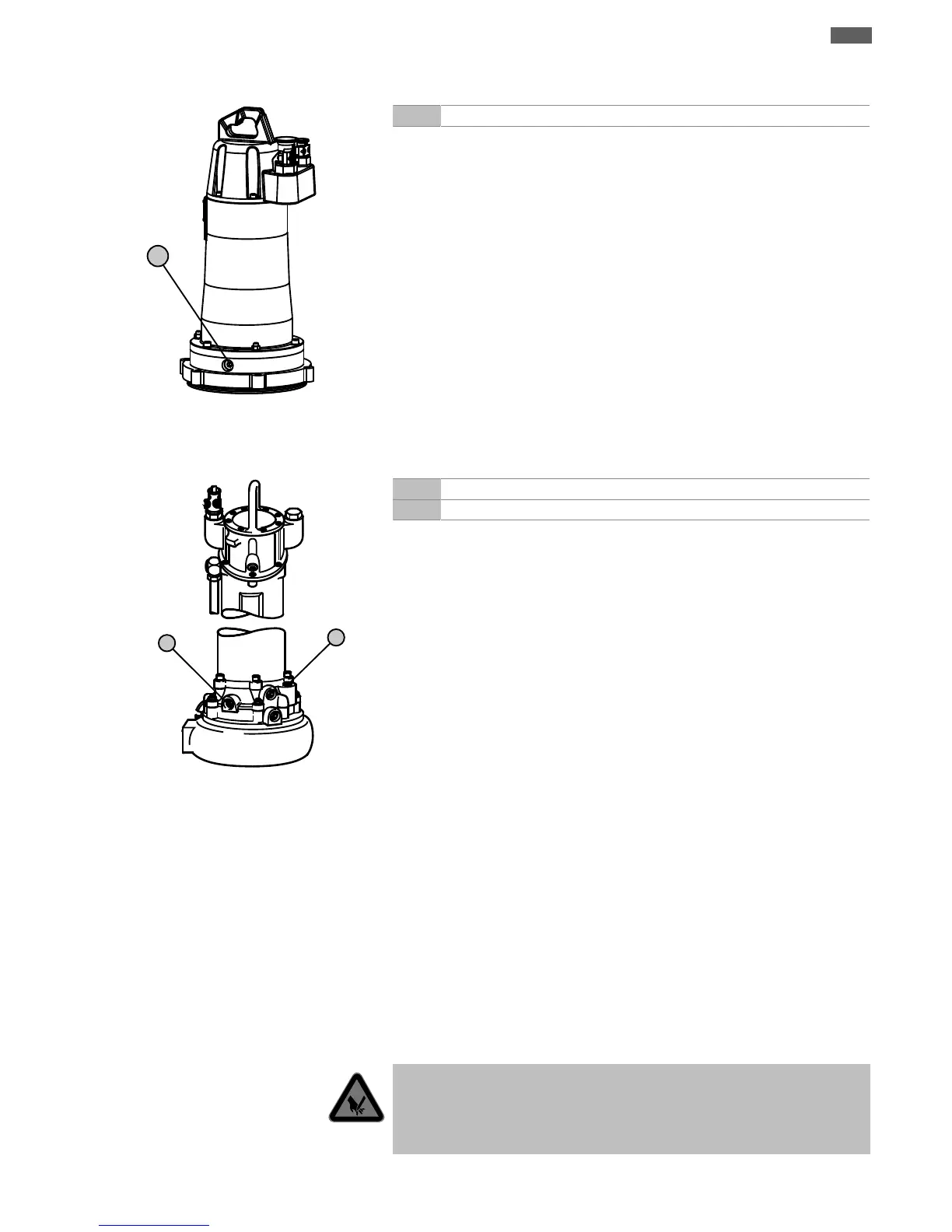

Motors FK 202, FK 34, FK 42

Fig.14: Sealing chamber: Oil change

+ Fill the oil in the sealing chamber

- Drain the oil in the sealing chamber

‡ Protective equipment has been put on!

‡ Pump has been dismantled and cleaned (decontaminated if required).

1. Place the pump upright on a firm surface.WARNING!Risk of hands being crushed.

Ensure that the pump cannot fall over or slip away!

2. Place a suitable tank to collect the operating fluid.

3. Unscrew the screw plug (+) slowly, but do not unscrew it completely. WARN-

ING!Overpressure in the motor! Stop turning the screw plug further if hissing

or whistling is audible! Wait until the pressure has completely dissipated.

4. After the pressure has dissipated, fully unscrew the screw plug (+).

5. Unscrew screw plug (-) and allow the operating fluid to drain out. If a shut-off ball

cock is installed on the outlet opening, open the shut-off ball cock.

6. Check the operating fluid: Notify customer service if an operating fluid contains

metal chips!

7. If a shut-off ball cock is installed on the outlet opening, close the shut-off ball

cock.

8. Clean the screw plug (-), replace the seal ring and screw it back in. Max. tightening

torque: 8Nm!

9. Pour the new operating fluid in through the hole of the screw plug (+).

⇒ Comply with the specifications for operating fluid locations and quantity!

10.Clean the screw plug (+), replace the seal ring and screw it back in. Max. tightening

torque: 8Nm!

9.6.9 General overhaul

During the general overhaul, the motor bearings, shaft sealings, O-rings and power

supply cables are checked for wear and damage. Damaged components are replaced

with original parts. This will ensure correct operation.

The general overhaul is performed by the manufacturer or an authorised service centre.

9.7 Repairs

WARNING

Sharp edges on the impeller and suction port

Sharp edges can form on the impeller and suction port. There is danger of limbs be-

ing cut-off! Protective gloves must be worn to protect from cuts.

Loading...

Loading...