VAC

MOTOR

1.

Remove hose from exhaust horn on

motor.

2.

Remove

(2)

screws holding vac ex

-

haust deflector. set aside.

3.

Tilt machine back on handle. Remove

(2)

bolts holding vac motor mounting

bracket

to

base. Return machine to

upright position. Disconnect wire

leads

ar?d remove vac motor.

4.

To inspect motor brushes, remove

brush holder assembly. Brushes

should be replaced when worn to

318

inch or after about

750

operating

hours. After second brush replace

-

ment, the armature commutator

should be checked for pitting and

concentricity.

Vac motors can be re

-

paired but such repairs should be

made by a qualified motor repair shop.

.

-

"

-

-

-

A

PUMP ASSEMBLY

1.

Disconnect pump motor leads. Re

-

move (4) screws holding pump to

chassis. Disconnect solution hoses

from pump head and lift out pump.

Refer to pump drawing for replace

-

ment parts.

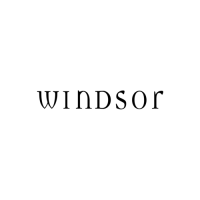

CAUTION:

When replacin

hose

-

barbs

on pump head

-

DO NO?

OVER

-

TIGHTEN

-

as this could crack intake

and exhaust ports in pump head.

WARNING:

The internal solution

hoses are encased

in

an outer hose

to

protect the electrical component parts

in the unlikely event a solution hose

should rupture. Replace hoses exactly

as

originally supplied.

SOLENOID & SOLUTION VALVES

1. Remove recovery and solution tanks.

2.

Remove auxiliary solution Outlet

nipple.

3.

Remove solution valve lever.

4.

Remove

(2)

screws holding valve

clamp chassis.

5.

Lift out valve asm. and disconnect

solution hoses. Repair as required.

NOTE:

The solenoid valve can be dis

-

assembled for cleaning when positive

shut

-

off is interrupted and valve leaks

through tee jets.

6.

Remove hex nut at top of valve and

lift off coil assembly.

7.

Use spanner wrench or small punch

and hammer to remove plunger body.

Remove lint and soap residue from

p

I

u

n g e r

.

CAUTION:

When re

-

installing valve

make sure arrow is pointed in the di

-

rection of solution flow.

sff.

A.

HEX

NUT

C.

WASHER

F.

PLUNGER

0.

PLUNGER

BODY

0.

VALVE

BODY

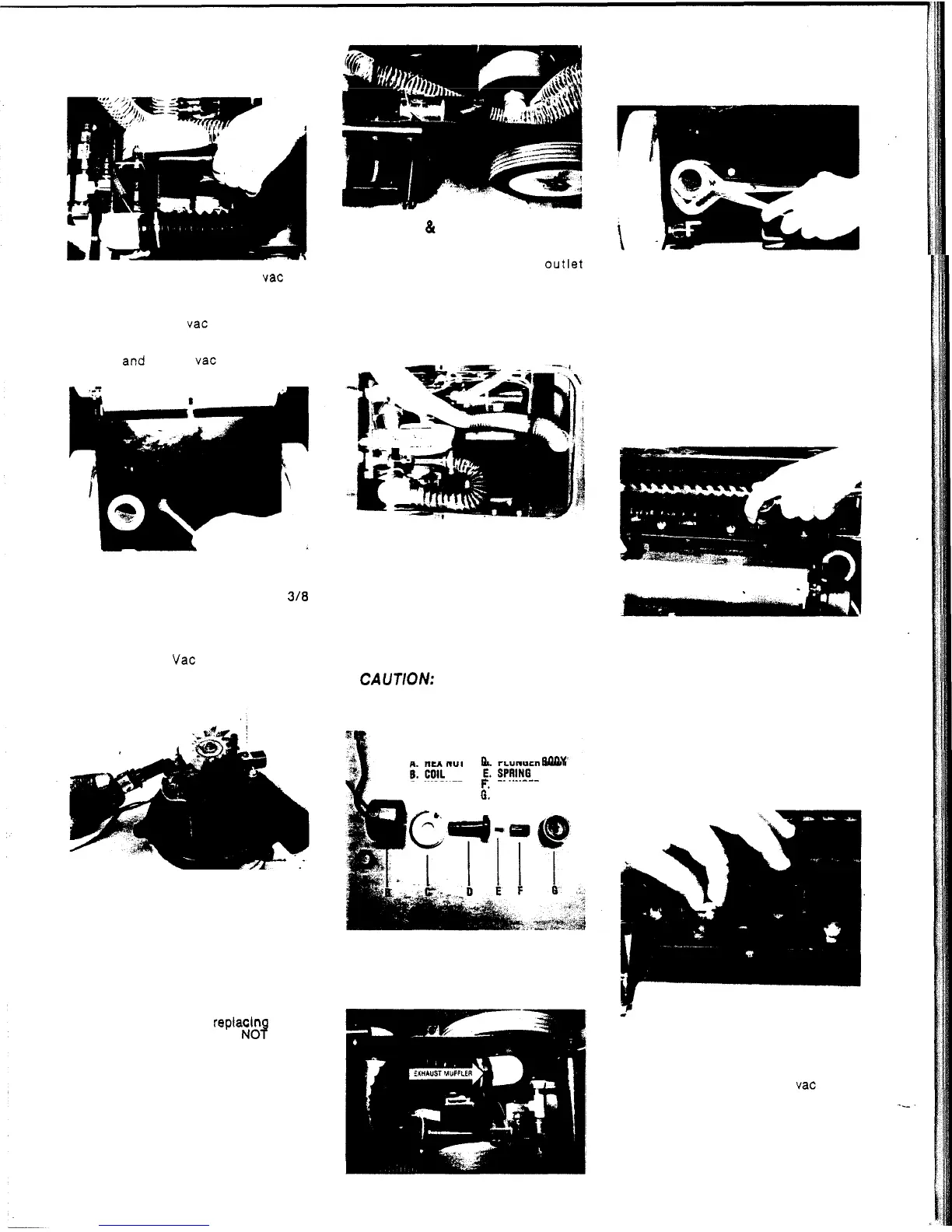

2.

Tilt machine back on handle. Remove

exhaust deflector and Hex retaining

nut from PVC muffler. Repair or

replace as required.

MAN

I

FOLD ASSEMBLY

1.

Remove pump from chassis

to

access

solution outlet hose.

2.

Remove hose from hosebarb.

3.

Tilt machine back on handle. Remove

(2)

screws holding manifold

to

chassis.

Remove manifold and repair as re

-

required.

SPRAY JETS

To prevent clogged jets due to alkaline

build

-

up, the spray system should be

flushed with 1 or

2

gallons

of

clean hot

water at the end of each day. The machine

is

equipped with

"

quick change

"

jets

that can be easily removed for cleaning.

To remove

-

push jet in and rotate 1/4

turn. Wash jets and blow dry.

Do

not

use pins or wire

to

remove obstruction

as this will change spray pattern.

VAC EXHAUST MUFFLER

1. Remove exhaust hose from muffler

elbow.

BRUSH

DRIVE MOTOR

1. Remove exhaust hose from vac motor.

2.

Disconnect motor lead wires.

3.

Move brush adjustment lever to

lowest

position and tilt machine back on

handle.

4.

Remove

(4)

motor retaining bolts.

4

Loading...

Loading...