A

1

2

3

4

5

6

A

DOCUMENT NO.: QR-208/A

B C D E

B

C

D E

1

2

3

4

5

6

SCALE

SIZE

DATENAME

APPROVALS

APP. BY

CUSTOMTER

DRAWN BY

CHECKED BY

1:1

A4

更 改 记 录

次 号

1.

2.

3.

VER.A0

SHEET

OF

PART Number: X-XXX-XXX-XX

1 1

WT8811 (WINTACT) 中 文 有 唛说明 书 示意图

日 期

更 改 内 容

71688811001

MJP

2018-04-09

SHENZHEN JUMAOYUAN SCIENCE AND TECHNOLOGY CO., LTD.

71688811001

WT8811 中文有唛说明书

材料:105G双铜;

页数: ( )

成品尺寸:190*130MM; 公差:+-1.0MM;

工艺:单色双面印刷,加工:装订成册说明书;骑马钉

20P 封二及封三留空白

130.00 mm

95.00 mm

-13--12-

time (including calibration parameters) in the instrument can be restored

to factory state;

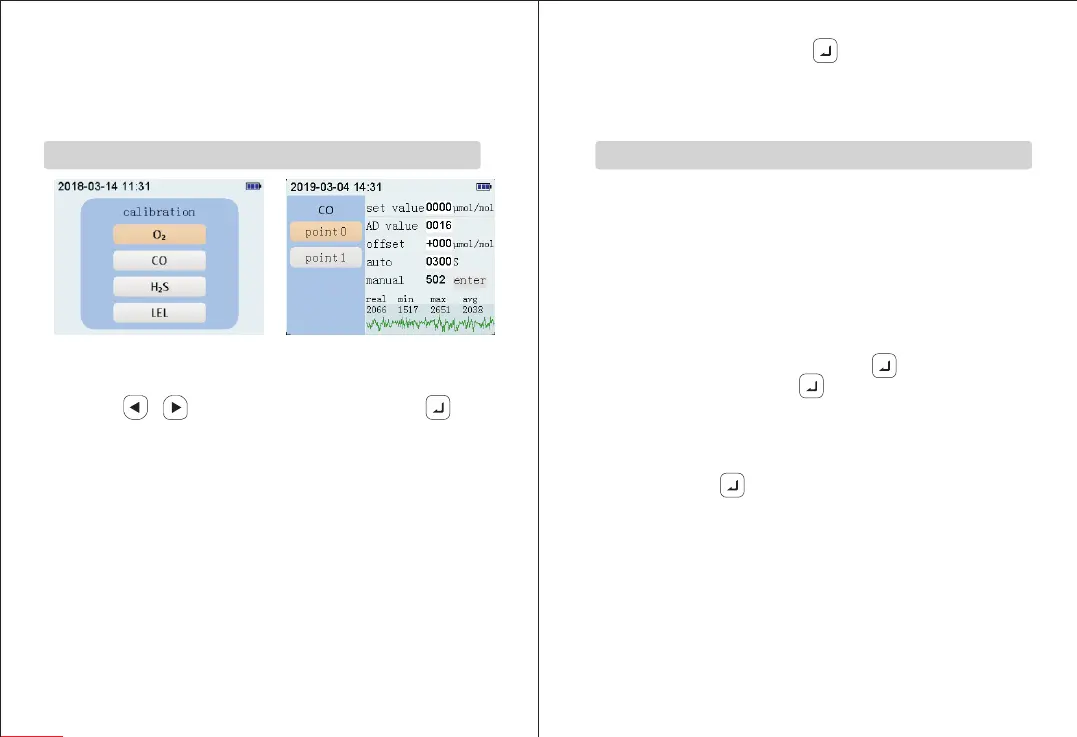

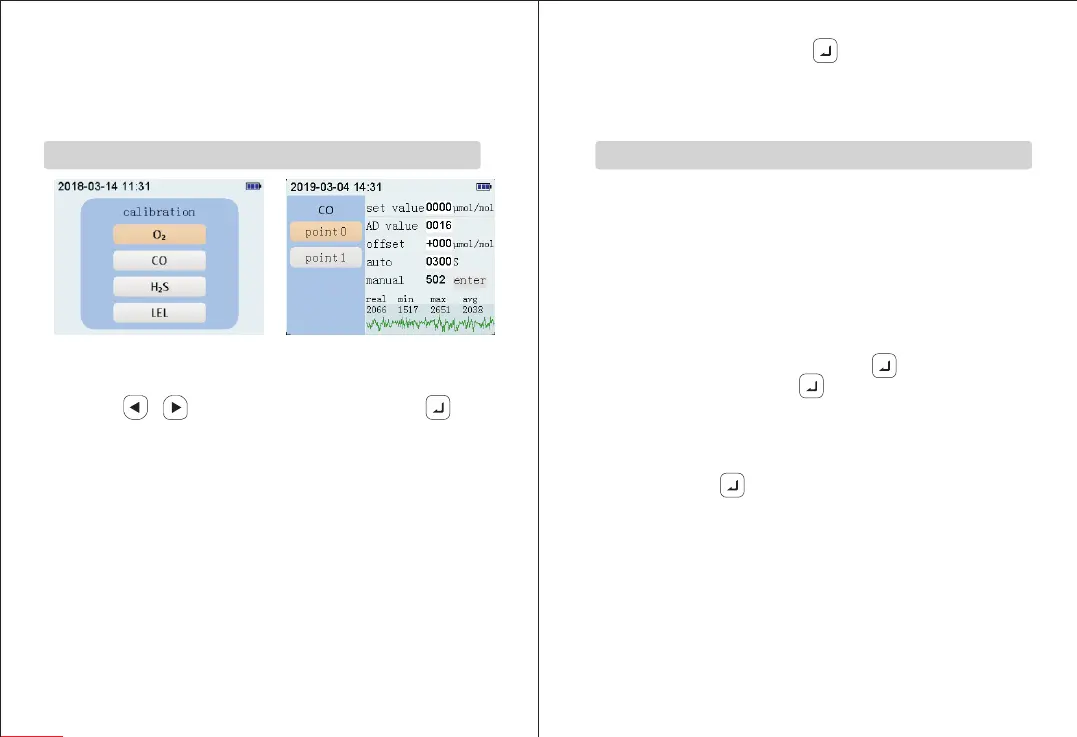

1. First enter the sensor calibration selection interface shown in Figure

8.1. Press“ ”/“ ” button to select a sensor; then press “ ” to

enter the single sensor calibration interface, as shown in Figure 8.2;

2. In the interface of Figure 8.2, the left side is the calibration point option,

the right side is the calibration parameter corresponding to each

calibration point, and the lower right area shows real-time value,

minimum value, maximum value, average value and curve of the sensor

signal; the concentration setting refers to setting the concentration value

to be calibrated; calibration AD value refers to the signal value output by

the sensor corresponding to the set concentration value; offset

adjustment refers to the reading plus or minus the set deviation on the

basis of the calibration point; timing calibration means that after the

timing calibration is on, the countdown of the set timing starts. When the

countdown reaches 0, the measured signal value is automatically stored

in the calibration AD value. Manual calibration means that when the

manual calibration is on, the real-time signal value is stored in the

3.Calibration Interface (ONLY FOR PROFESSIONAL)

Sensor Calibration Selection Interface

Sensor Calibration Selection

Interface (Figure 8.1)

calibration AD value by pressing “ ”button; the value between manual

calibration icon and ENTER icon is the real-time measured concentration

value.

Three Sensor Calibration Methods

1. there are three kinds of calibration methods:

1) Input the calibration AD value directly: a. Set concentration value;

b.Open to calibration gas which has set concentration value; c. Wait for

the signal curve at the lower right of screen to be stable; d. After the

signal is stable,input the real-time signal value to calibration AD value.

2) Manual Calibration: a. Set concentration value; b. Open to the

calibration gas which has set the concentration value; c. Wait for the

signal curve at the lower right of screen to be stable; d. After the signal

is stable, select manual calibration. Press “ ” button to confirm that

the icon will be selected. Press “ ” button again and the real-time

signal value will be added to the calibration AD value.

3) Timing calibration: a. Set the concentration value; b. Open to the

calibration gas with the set concentration value; c. Select timing

calibration, press “ ” button, input the timing, then countdown

starts, when the countdown reaches 0, the real-time signal value will

be added to the calibration AD value.

4) If the calibration is wrong, you can recalibrate or restore to factory

settings in system settings.

2. When calibrating the zero point of carbon monoxide, hydrogen sulfide,

and combustible gas, you can increase the calibration AD value by 5~9

to prevent the readings from appearing unrecoverable.

Sensor Calibration Interface

(Figure 8.2)

Loading...

Loading...