Service 24

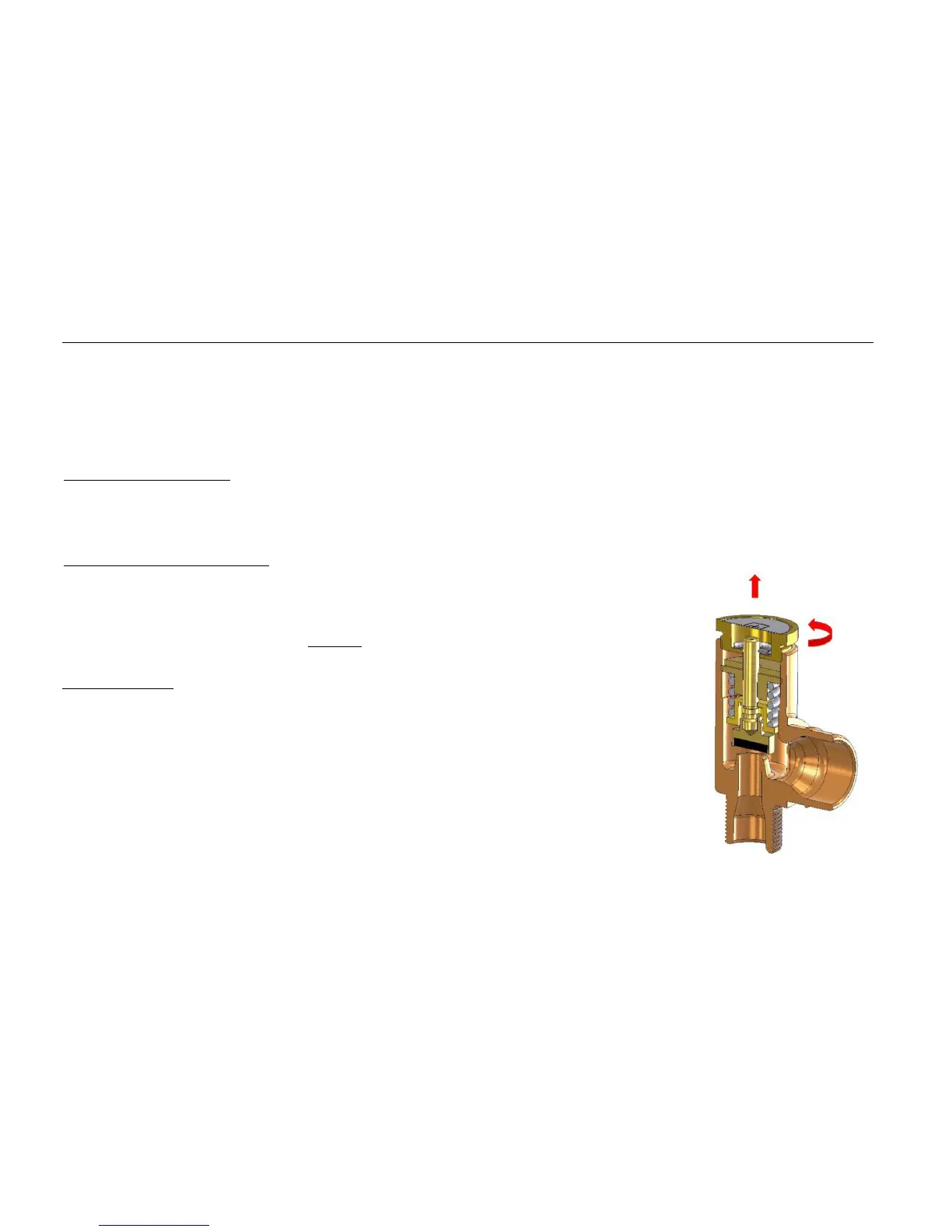

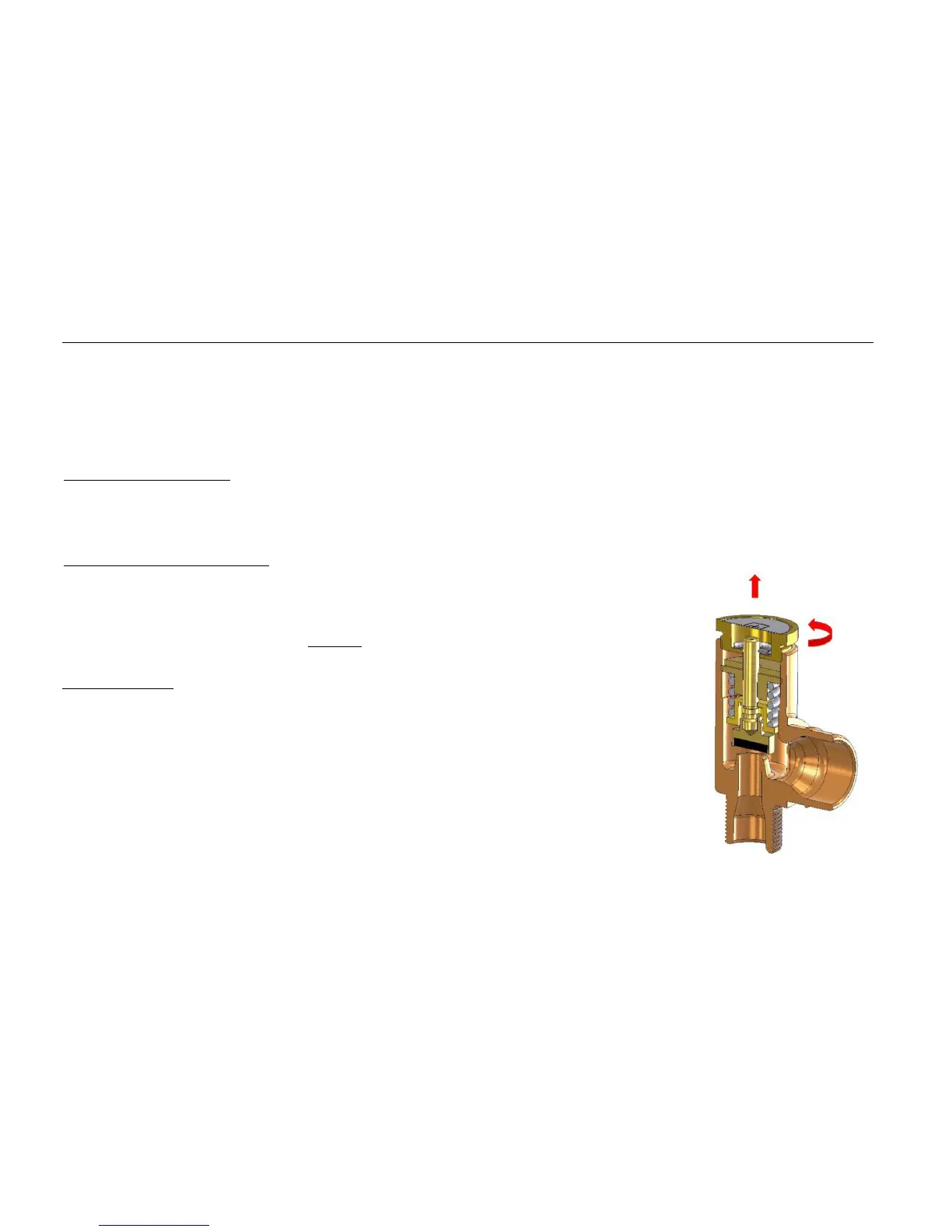

2.16 Safety valve – Procedure for performing a functional check

The safety valve is screwed onto the steam boiler via a pipe end. The pipe end is dimensioned so that the valve seal is exposed to a temperature load less than

80 °C. If functioning normally, the valve need not be replaced during the entire service life of the coffee machine.

Important note for technicians:

The safety valve must undergo a functional check at least 1 x year.

If an error situation arises, in which the safety valve was triggered, the safety valve will need to be replaced because its seal may be damaged.

Functional check / venting instructions

Disassemble to the level shown: Top cover and rear cover

The function is to be carried out at operating pressure

Gently unscrew the knurled nut on the safety valve (1/2 to max 1 turn max) until steam escapes

Afterwards, immediately tighten already at the stop.

Note for technicians:

The safety valve MUST NOT be vented in the pressureless state.

The knurled nuts must only be tightened ½ to a maximum of 1 rotation- otherwise,

the clamp collar may come off, which would compromise the accuracy of subsequent

functional checks.

Loading...

Loading...