CNC210 Operating Manual

1.main motor 2.Multi wedge belt 3.Z axis feed motor 4.Angular contact bearing 5.Deep

groove ball bearing 6. Spindle 7. Angular contact bearing 8.Longitudinal lead screw 9.Deep

groove ball bearing, 10, X axis feed motor 11.Synchronous belt 12.Angular contact bearing

2.13. Transverse lead screw 14.Deep groove ball bearing

Note: this drive system diagram, just roughly indicates the installation position of the

components. In the bearing distribution table, will be "close to the motor side", "far away

from the motor side" to explain the text.

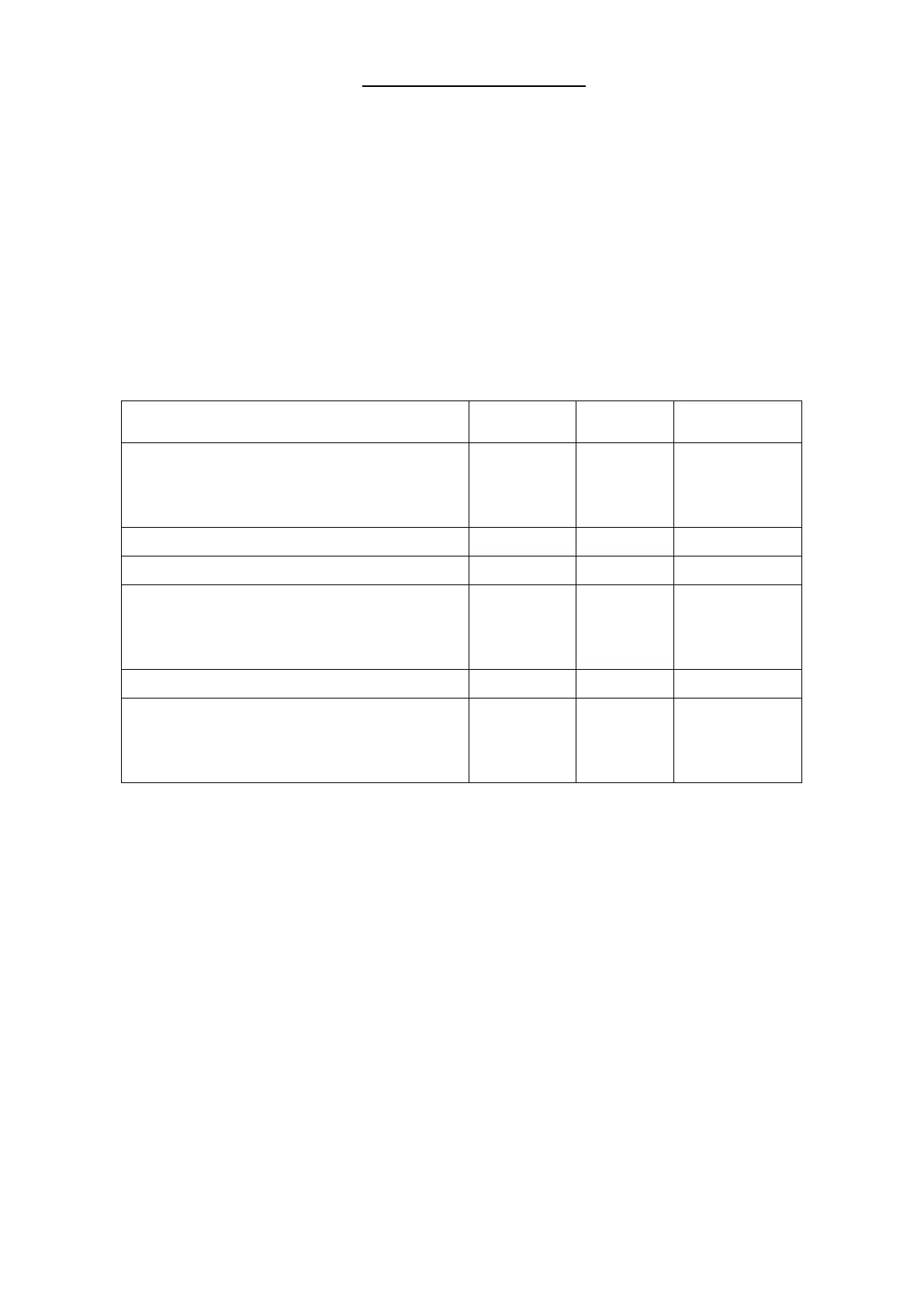

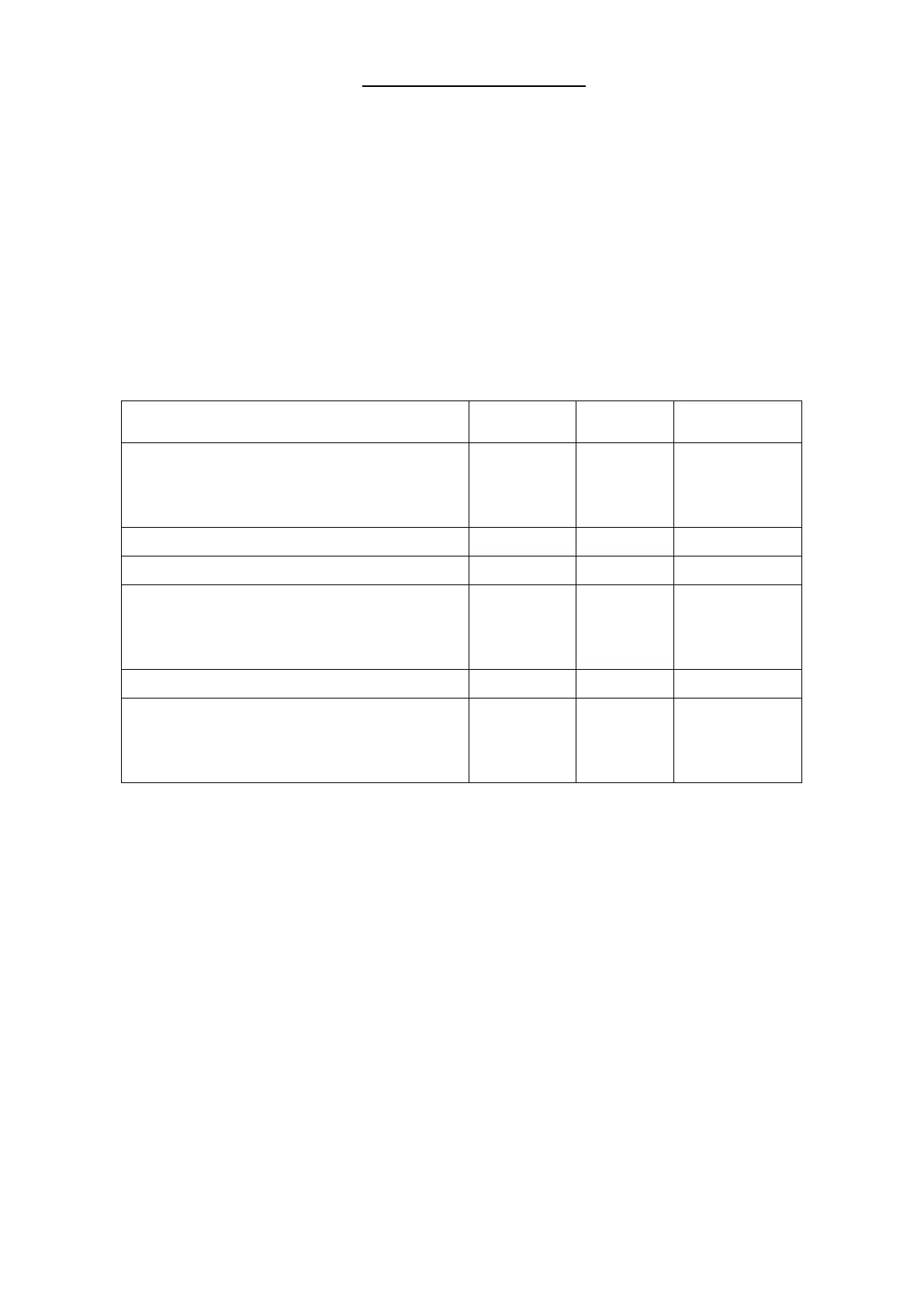

Table 5-1 important bearing distribution table

Note: bearing models refer to the country's latest standards.

5.2.1 Main drive system

The machine main motor direct drive spindle motor, spindle box has cancelled the gear

transmission mechanism, simple structure, easy maintenance, high reliability. Transmission

through the main motor by DC brushless motor, DC stepless speed regulation. Spindle positive

inversion through the electrical system control, positive inversion has the same speed.

5.2.2 Work piece clamping mechanism

The configuration of the machine tool work piece clamping mechanism is three jaw chuck

and the power source is manual .

Warning :

All tooling and work piece clamping mechanism installed on the spindle must consider its

dynamic balance, otherwise it will greatly damage the spindle bearings, severely punish will cause

the body to scrap or damage the safety of the operator.

5.2.3 Feed drive system

4 one pairs of Angular contact bearing

(Near the motor)

7 Deep groove ball bearing

9 one pairs of Angular contact bearing

11 Deep groove ball bearing(Far from the

motor)

14Angular contact bearing(Near the motor)

14 Deep groove ball bearing(Far from the

motor)

Loading...

Loading...