CNC210 Operating Manual

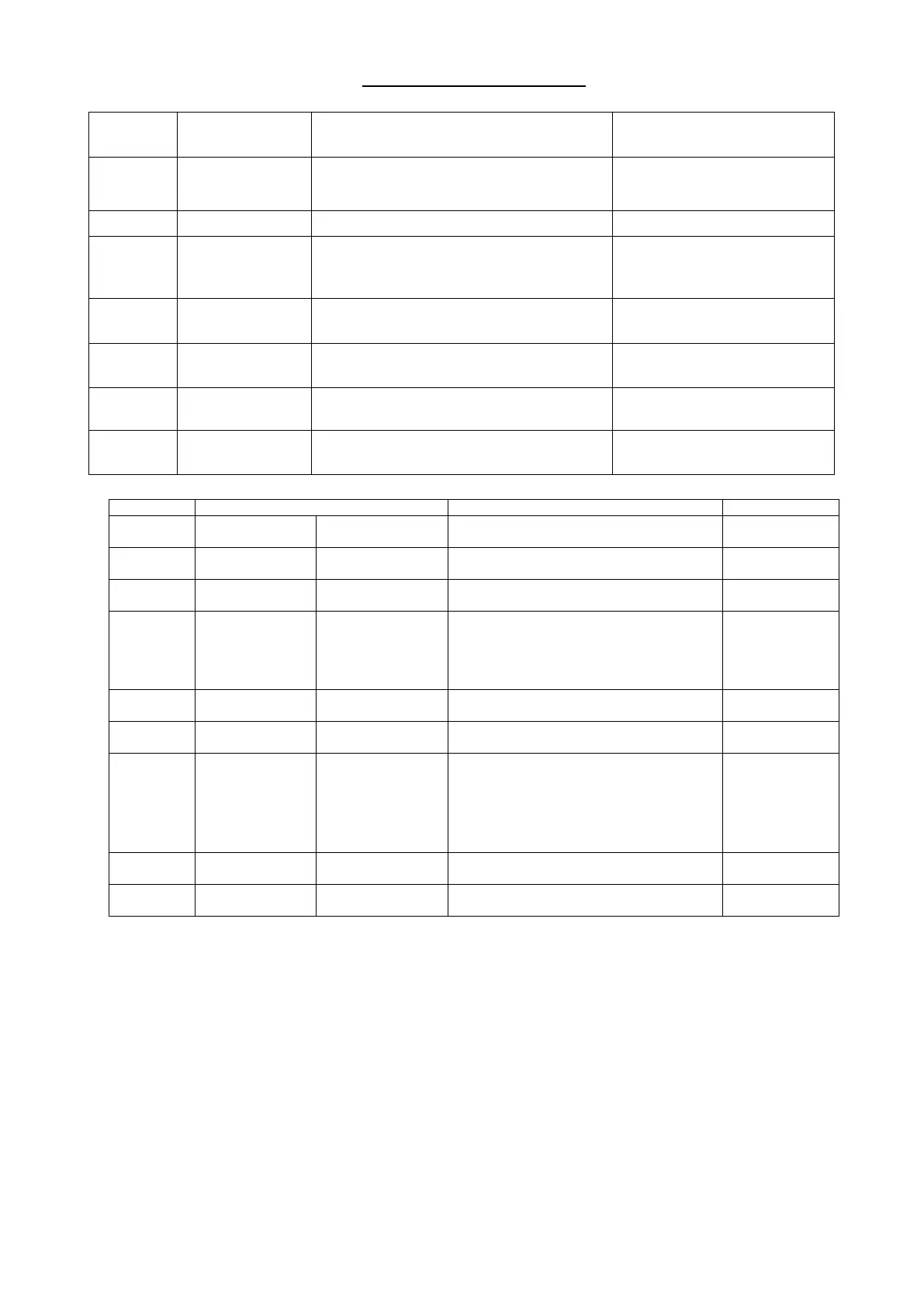

7.2 Regular check

Lubricating device

pipeline

Clean up the Version filter

Check for oil leakage, blockage and rupture.

Clean up the drain opening filter

Check appearance and tightness

Clean up the pulley

Sound, vibration,

temperature rise,

insulation resistance

Check the abnormal noise on the bearing and

any other parts.

Clean up the Belt pulley

Sound and

temperature rise

Check the abnormal noise and temperature

rise on the bearing.

Removing chuck and clean up the cutting

chips in the chuck

Electrical device

and connection

screw

Check whether the electrical device has

peculiar smell, color change, whether the

contact surface have wear and screw loose

Dust and so on

Check with gradienter and adjust the level of

the bed

7.3 lubrication and coolant

7.3.1 lubricating device

The items of check the lubricating device as below:

A: timely add the oil according to the provisions.

B: The lubricating parts’ check.To ensure that each of the lubricating parts can be well

lubricated, if the lubrication is not good somewhere, may be the lubrication pipeline blockage,

please remove the joint, clean or replace.

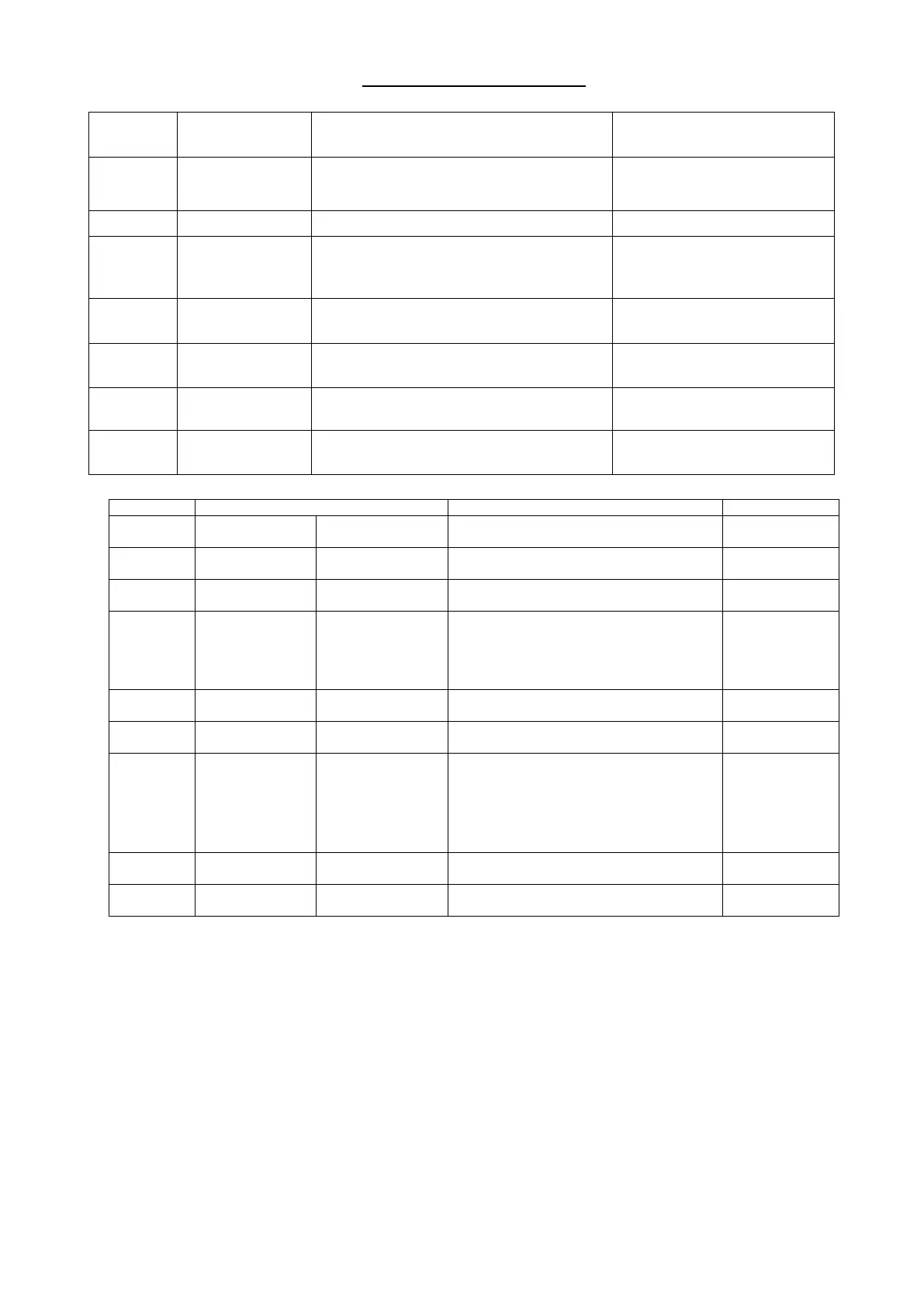

7.3.2 coolant device

The check items as below:

1. Whether there is noise and shake

2

.

Whether the shift is smooth and normal.

1

.

Whether the switch and the hand shank is

normal

2

.

Whether can display the alarm.

1. Whether there is break

2. there is no short circuit,whether the insulation

of wire is damaged.

Motor and other

rotating parts

1.Whether there have unusual noise and shake.

2.Whether there have abnormal fever.

Clean the surface of the chuck, X, Z axis guard

surface

Lubricating around the chuck

Whether the accuracy of the machine in a permit

range.

Loading...

Loading...