Spindle speeds

and

adjusting

belt tension

.

. .

.

WARNING:

Always

ensure that the

pillar

drill is switched

off and

NOTE A De“

9°S“‘°”'”9 Speed

m” ‘5

unplugged

from t e

power supply

before

making

and

adjustments

or

a

,

.-

.

.

loosed on the inside

top

coverot the

p.llar

drill

changing

a

drill bll,

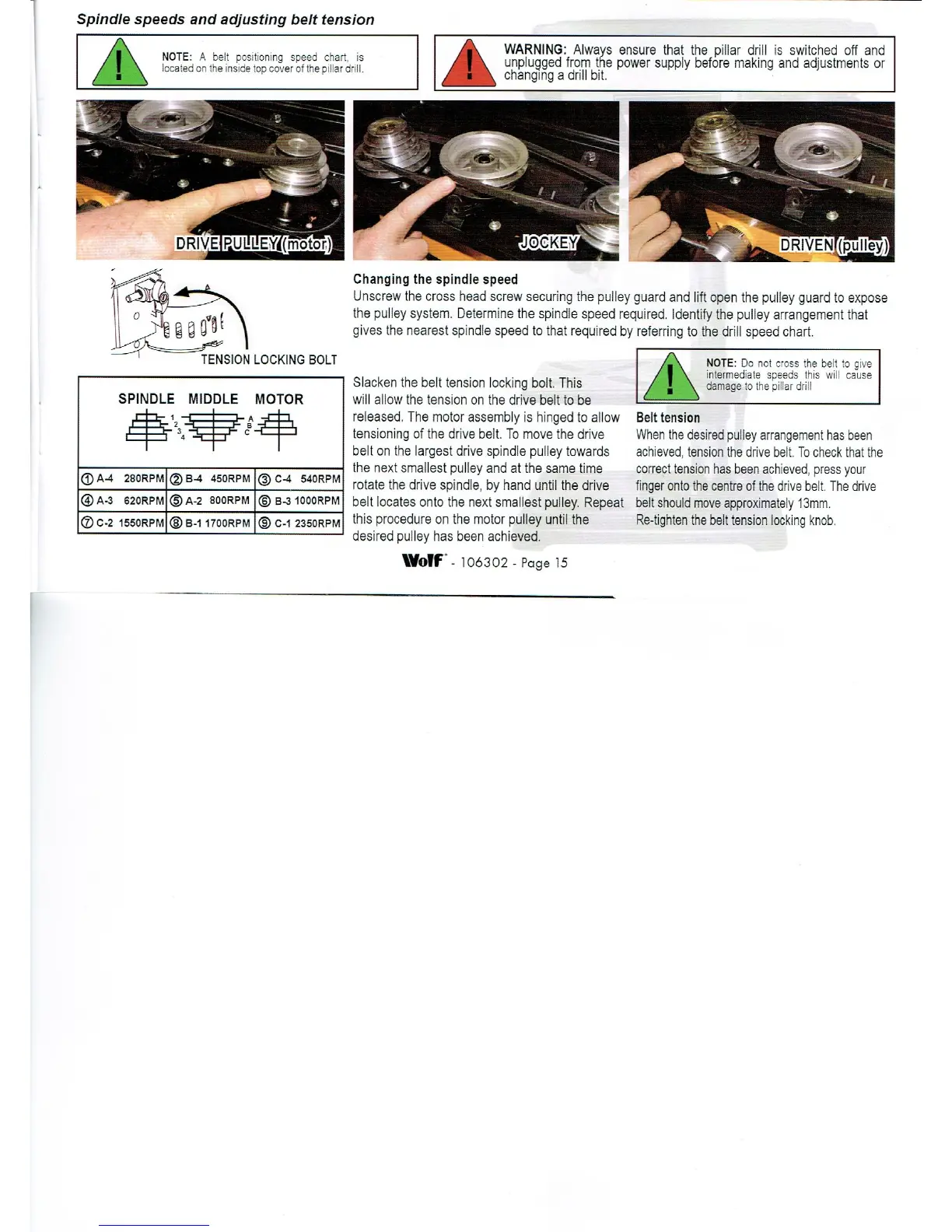

Changing

the

spindle

speed

Unscrew

the cross head screw

securing

the

pulley guard

and

lift

open

the

pulley guard

to

expose

the

pulley system.

Determine the

spindle speed required.

Identify

the

pulley

arrangement

that

gives

the nearest

spindle speed

to

that

required by referring

to the drill

speed

chart.

NOTE:

dDo

not cross

the belt to

gave

.

, .

inlerme late 5 eeds

this wr‘l cause

Slacken the belt

tension

locking

bolt. This

damage

to the

gillardfllt

‘

will allow the

tension on the drive belt to be

released The

motor

assembly

is

hinged

to

allow Belt

tension

tensioning

of

the drive belt. To move the

drive When the

desired

pulleyarrangement

has been

belt on

the

largest

drive

spindle

pulley

towards

achieved,

tension the drive belt. To check that the

1

A

13‘

E

the

next smallest

pulley

and at the same

time correct

tension has been achieved.

press

your

rotate

the

drive

spindle. by

hand until

the drive

finger

onto the centre of the drive belt. The drive

belt locates onto the next smallest

pulley. Repeat

belt should move

approximately

13mm

this

procedure

on the motor

pulley

until the

Re-tighten

the belt tension

locking

knob.

desired

pulley

has been

achieved.

\Volf'

.

l06302

—

Page

15

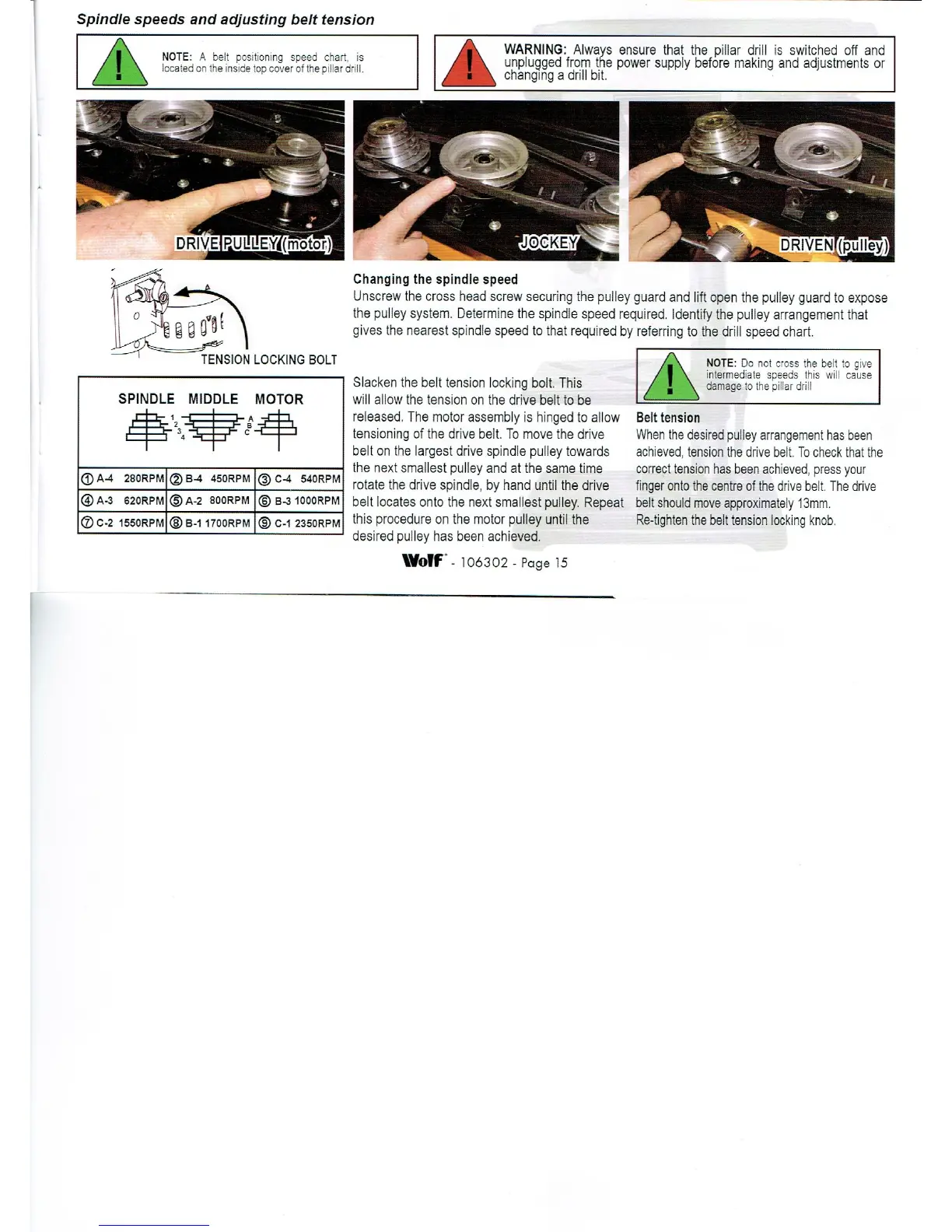

SPINDLE MIDDLE

MOTOR

Loading...

Loading...