20. Control Board.

Check that the electricity supply to the appliance is turned off.

Undo the 3 screws and remove the facia bottom panel.

Remove the two upper screws and hinge down the facia

assembly.

Carefully pull off all the connectors. Disconnect the mains supply

lead at terminal X1 and the earth connection at the back.

Remove the four corner screws on the back of the facia and

separate the metal back panel from the plastic facia.

Remove and retain the brass nut and washer.

Release the six pillars on the control board and pull the control

board forward off the back panel.

Fit the replacement board in the reverse order ensuring it is

pushed firmly onto the six pillars and clicks into place. Special

care should be taken with the brass post and nut to ensure a

good earth contact. (Check earth continuity between the

incoming earth and the appliance chassis).

Refit the facia panel and hinge the control box assembly in the

servicing position as described in Section 14.3 (c).

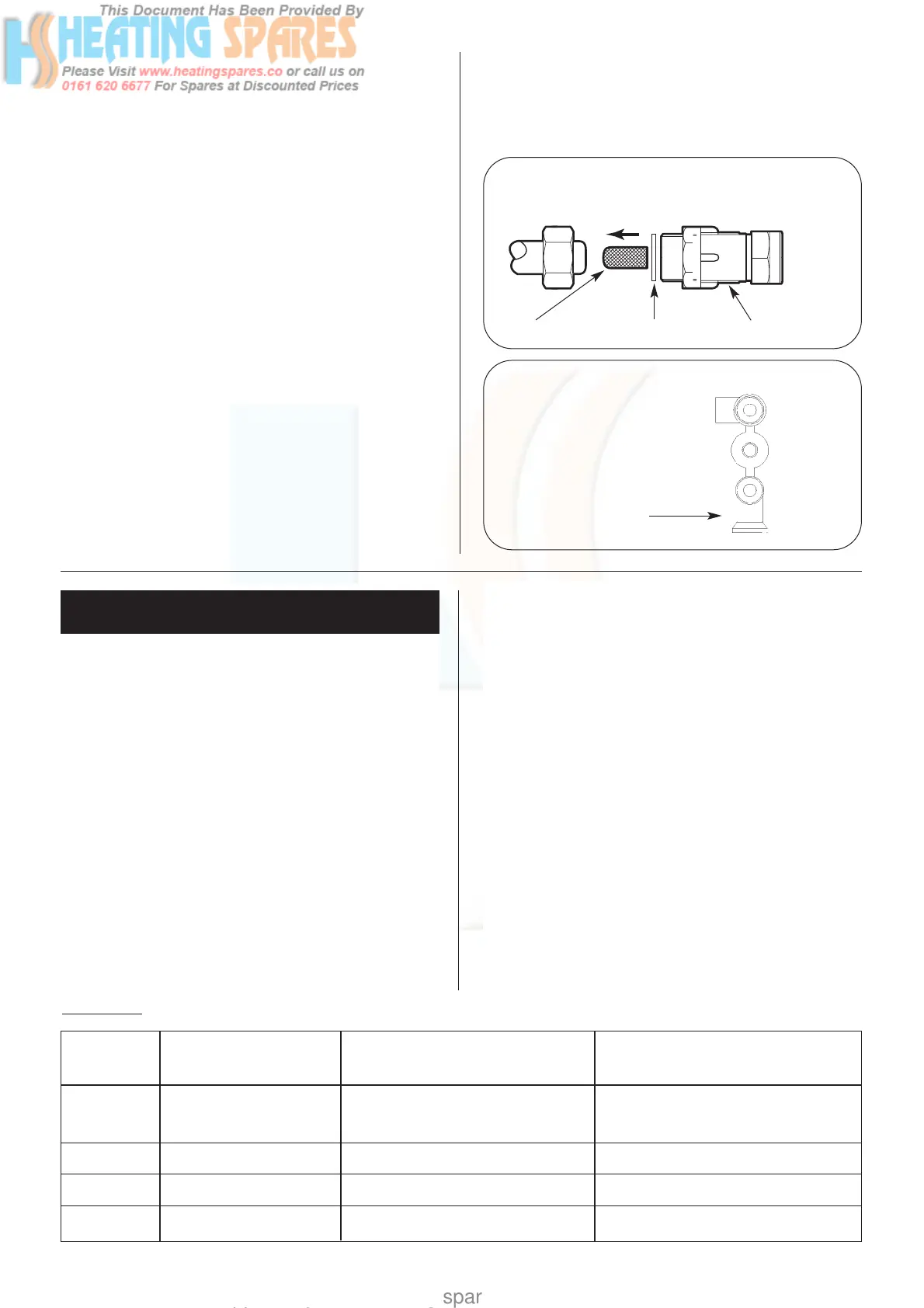

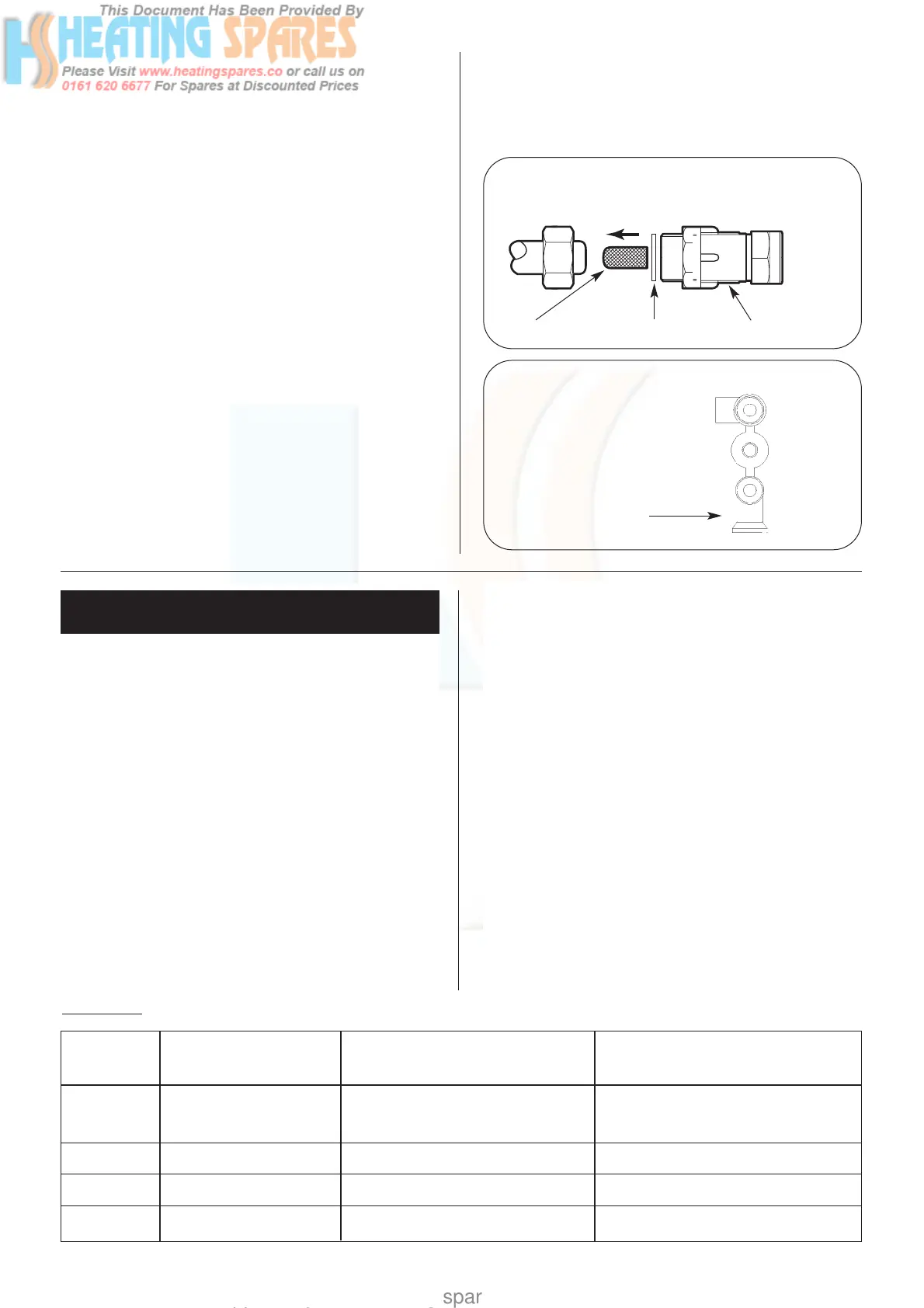

21. Gauze filter. See Fig. 39.

Remove the water flow switch as described in section 15.4-17.

Undo the lower union nut on flow switch housing.

Undo the nut on the isolating valve and remove the mains water

inlet pipe. Carefully extract the filter from the valve end of the pipe.

Replace the filter and refit the pipe in reverse order using a new

fibre washer.

22. Flue flow sensor. See Fig. 40.

Check that the electricity supply to the appliance is turned off.

Remove the fan assembly as described in Section 14.3(e).

Unscrew the single central retaining screw and withdraw the

sensor from the fan.

Fit the new sensor ensuring the correct orientation and carefully

tighten the retaining screw.

Refit the fan assembly in reverse order.

23

Fig. 39. Gauze Filter.

Gauze Filter

Positive

Isolating Valve

These instructions should be used when converting appliances

from natural gas to LPG and vice versa.

Only components supplied by Worcester Heat Systems should

be used.

Only competent persons should attempt the conversion.

Conversion from Natural Gas to LPG should not be carried

out on appliances installed in a room or internal space below

ground level.

1. Ensure the gas service cock is turned OFF and the electrical

supply is isolated.

2. Refer to section 14.3 Dismantle the Appliance to remove the

boiler front panel and inner casing. Follow the dismantling

instructions to remove the burner.

3. Remove the injector and replace with the injector from the

kit.

4. Remove the nut, end cap and bracket from the end of the

burner.

4.1 For conversion to Natural gas remove the internal gauze.

4.2 For conversion to LPG fit the gauze into the burner body.

5. Refit the end cap ensuring the bracket is in the correct orien-

tation.

6. Refit the burner to the appliance and re-assemble the inner

casing.

7. Follow the dismantling instructions to remove the gas valve

and refit the new valve. See Installation Instructions: Section

15.4.11 Replacement of Parts, Component Replacement, Gas

Valve.

8. Turn on the gas and electricity supplies and following the

commissioning procedure confirm gas soundness and correct

boiler operation.

9. Set the gas pressure to the required rate for the new gas type

as specified on the data plate. When this is done refit the cap to

the adjuster and seal its retaining screw with paint or nail var-

nish.

10. Turn off the boiler and when cool peel off the arrow from

the data plate and re-stick it against the gas type for which the

appliance is now converted.

11.Replace the boiler front panel.

The conversion is now complete.

16. Conversion Instructions

Item No. Description Natural Gas to LPG Kit LPG to Natural Gas Kit

7 716 192 131 7 716 192 132

1. Burner Injector 8 716 140 209 8 716 105 033

Stereomatic 2.78mm Stereomatic 4.3mm

2. Burner Gauze 8 716 142 601 Remove Gauze

3. Gas Valve 8 716 142 430 8 716 142 413

4. Copper Washer 8 716 101 994 8 716 101 994

Parts List

Fig. 40. Flue flow sensor.

Fibre Washer

Loading...

Loading...