PRE-

IN STALLATION

INSTALLATION & SERVICING INSTRUCTIONS FOR WORCESTER BOSCH

PRE-

IN STALLATION

INSTALLATION & SERVICING INSTRUCTIONS FOR WORCESTER BOSCH

8-716-106-256a (08.05)

9

WATER SYSTEMS & PIPEWORK

WATER SYSTEMS & PIPEWORK

PRIMARY SYSTEM PLASTIC PIPEWORK:

Any plastic pipework must have a polymeric

barrier with 1000mm (minimum) length of copper

or steel pipe connected to the boiler.

Do not use plastic pipework on sealed systems.

Plastic pipework used for underfloor heating

must be correctly controlled with a thermostatic

blending valve limiting the temperature of the

circuits to approx. 50°C. The pipework from the

boiler to the blending valve must be in copper

or steel (protected from corrosion).

PRIMARY SYSTEM/CONNECTIONS/VALVES:

Do not use galvanised pipes or radiators.

All system connections, taps and mixing valves

must be capable of sustaining a pressure of 3

bar.

Radiator valves should conform to BS2767:10.

All other valves should conform to BS1010.

On new installations TRVs must be used on all

radiators except the radiator where the room

thermostat is sited, this must be fitted with

lockshield valves and left open. All installations

should have TRV's fitted to radiators within the

sleeping accommodation.

An automatic bypass valve must be connected

between the heating flow and return where TRV's

are used on all radiators.

Drain cocks are required at all the lowest points

on the system.

Air vents are required at all high points on the

system.

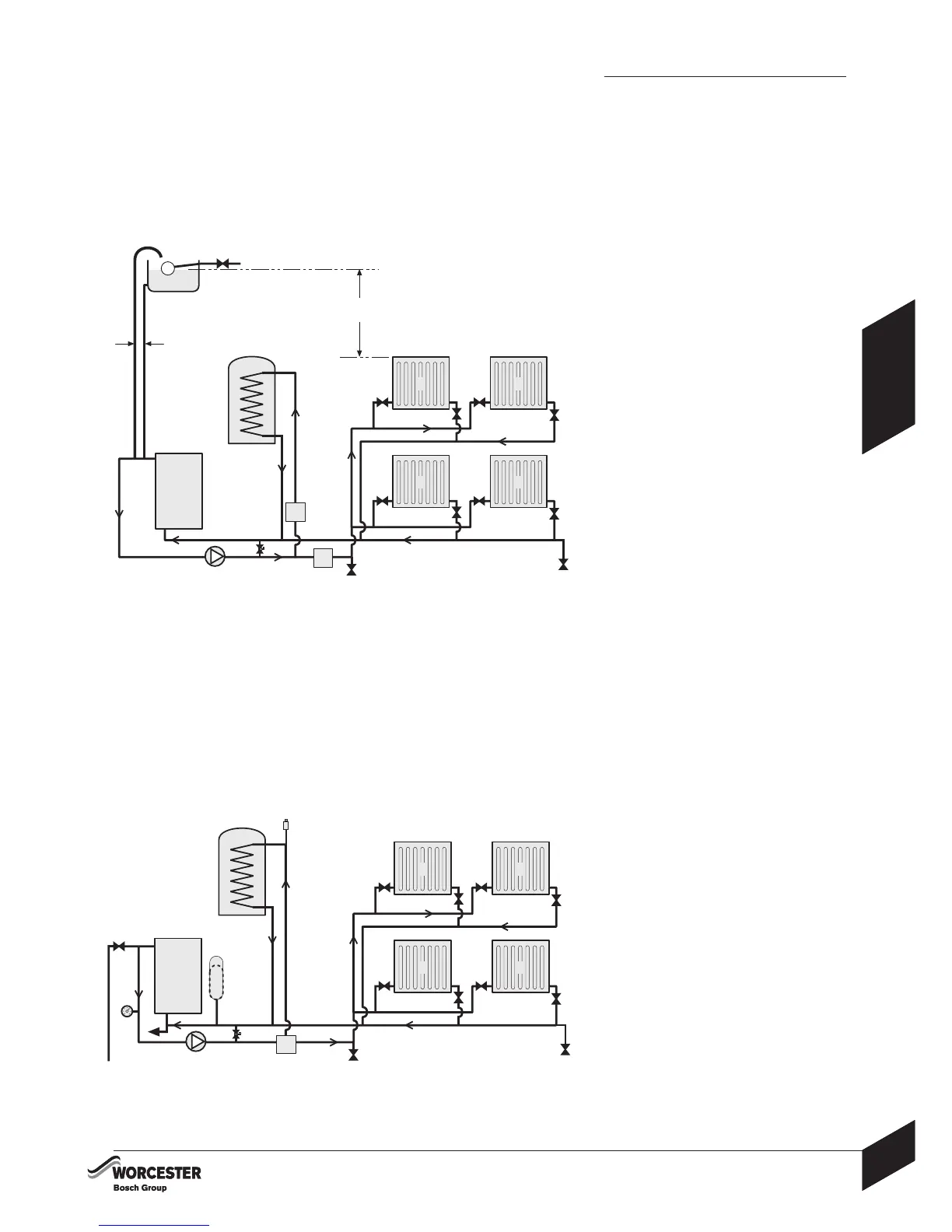

OPEN VENT PRIMARY SYSTEM:

The feed and expansion cistern (E) must be

positioned to provide a static head (S) of at least

1 metre above the highest point in the heating

system to the water level in the feed and

expansion cistern (E).

The heating vent (H) and cold feed (F) pipes

must rise continuously from the appliance.

The heating vent pipe (H) must be at least

22mmØ.

No valve shall be fitted in the open vent pipe (H)

or the feed and expansion pipe (F).

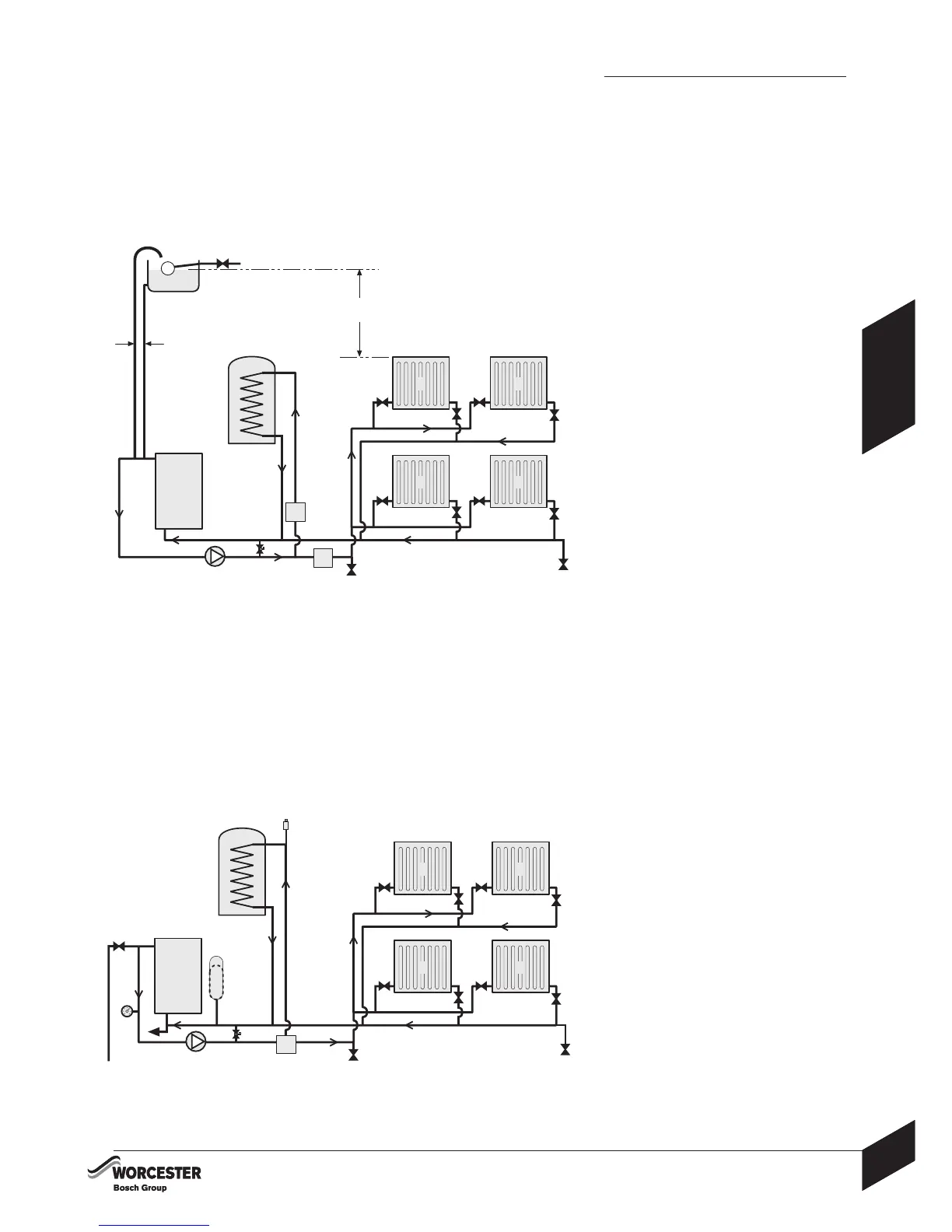

FULLY PUMPED SEALED PRIMARY SYSTEM:

A pressure relief valve (P) (spring loaded safety

valve set to operate at 3 bar) must be fitted to

the heating flow pipe as close as possible to

the boiler or onto one of the boiler top 1" BSP

outlets.

An expansion vessel (B) must be fitted to the

heating return pipe close to the boiler and

pressurised for the system volume according to

the instructions supplied with the vessel.

A pressure gauge (G) (3 bar min.) must be fitted

to the heating flow pipe or one of the boiler 1"

BSP outlets.

An automatic air vent (N) must be fitted.

TYPICAL SEALED SYSTEM:

TYPICAL OPEN VENT SYSTEM:

A - Appliance

B - Expansion vessel

C - Automatic bypass valve

D - Drain cock

E - Feed and expansion cistern

F - Feed and expansion

15mmØ min

G - Pressure gauge

H - Open vent 22mmØ min

J - Circulating pump

K - Zone valve

L - Lockshield valve

M - Hot water cylinder

N - Automatic air vent

P - Pressure relief discharge

R - Radiators

S - Static head

T - TRV

U - To filling system

A

D

R R

R R

B

P

D

C

T

L

T

L

T

L

T

L

E

S

1000mm min.

FH

G

JK

M

N

A

D

R R

R R

D

C

T

L

T

L

T

L

T

L

J

K

M

150mm max.

K

U

Loading...

Loading...