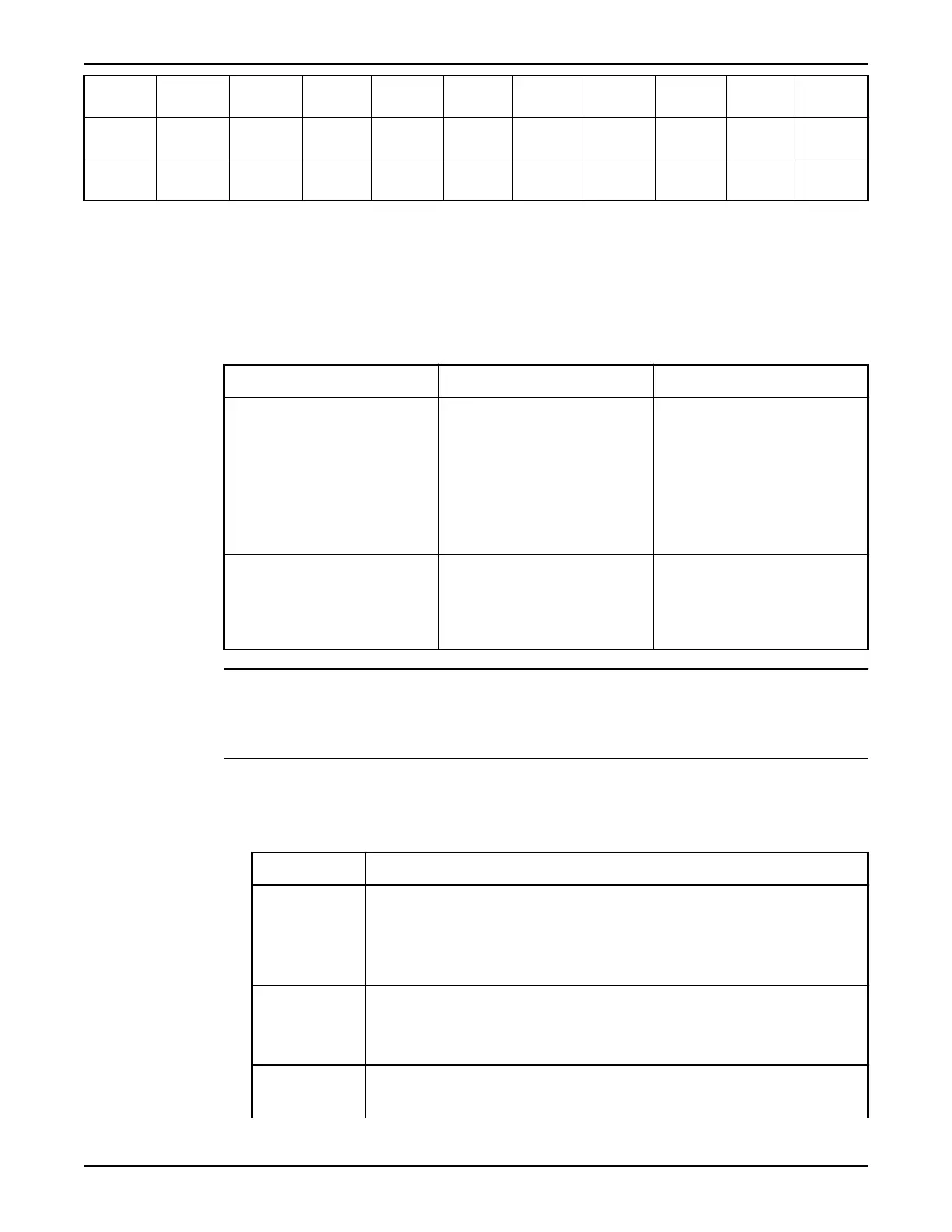

Property

class

M4 M5 M6 M8 M10 M12 M16 M20 M24 M30

10.9 4.0 (2.9) 8.1 (6) 14 (10) 33 (24) 65 (48) 114 (84) 277 (204) 541 (399) 935 (689) 1840

(1357)

12.9 4.9 (3.6) 9.7 (7.2) 17 (13) 40 (30) 79 (58) 136 (100) 333 (245) 649 (480) 1120

(825.1)

2210

(1630)

Hexagon screws with countersunk heads

For hexagon socket head screws with countersunk head, maximum torque for all property

classes must be 80% of the values for property class 8.8 above.

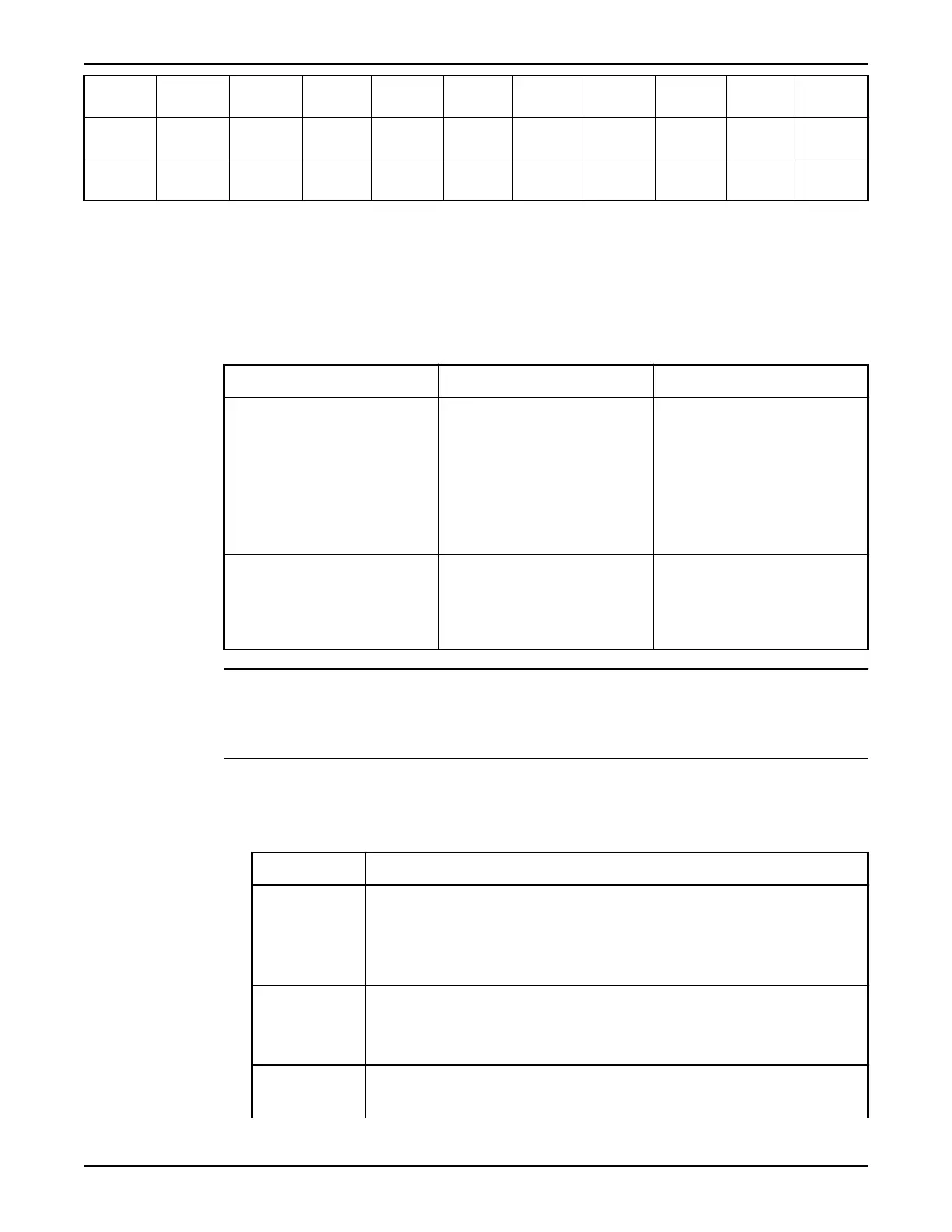

Service

Regular inspection and service of the pump ensures more reliable operation.

Type of service Purpose Inspection interval

Inspection To prevent operational interruptions

and machine breakdown. Measures

to secure performance and pump

efficiency are defined and decided

for each individual application. It

can include such things as impeller

trimming, wear part control and

replacement, control of zinc-anodes

and control of the stator.

Twice a year

Major overhaul To secure a long operating lifetime

for the product. It includes

replacement of key components

and the measures taken during an

inspection.

Every year, under normal operating

conditions

NOTICE:

Shorter intervals may be required when the operating conditions are extreme, for example

with very abrasive or corrosive applications or when the liquid temperatures exceed 40°C

(104°F).

Inspection

Regular inspection and service of the pump ensures more reliable operation.

Service item Action

Visible parts on

the pump and

installation

1. Check that all screws, bolts, and nuts are properly tightened.

2. Check the condition of lifting handles, eye bolts, ropes, chains, and wires.

3. Check for worn or damaged parts.

4. Adjust and/or replace if necessary.

Pipes, valves,

and other

peripheral

equipment

1. Check for worn or damaged parts.

2. Adjust and/or replace if necessary.

Pump casing and

impeller

1. Check for worn or damaged parts.

2. Adjust and/or replace if necessary.

Maintenance

Flygt 2125 Installation, Operation, and Maintenance Manual 27

Loading...

Loading...