Maintenance and Repair 1300 YRM 1330

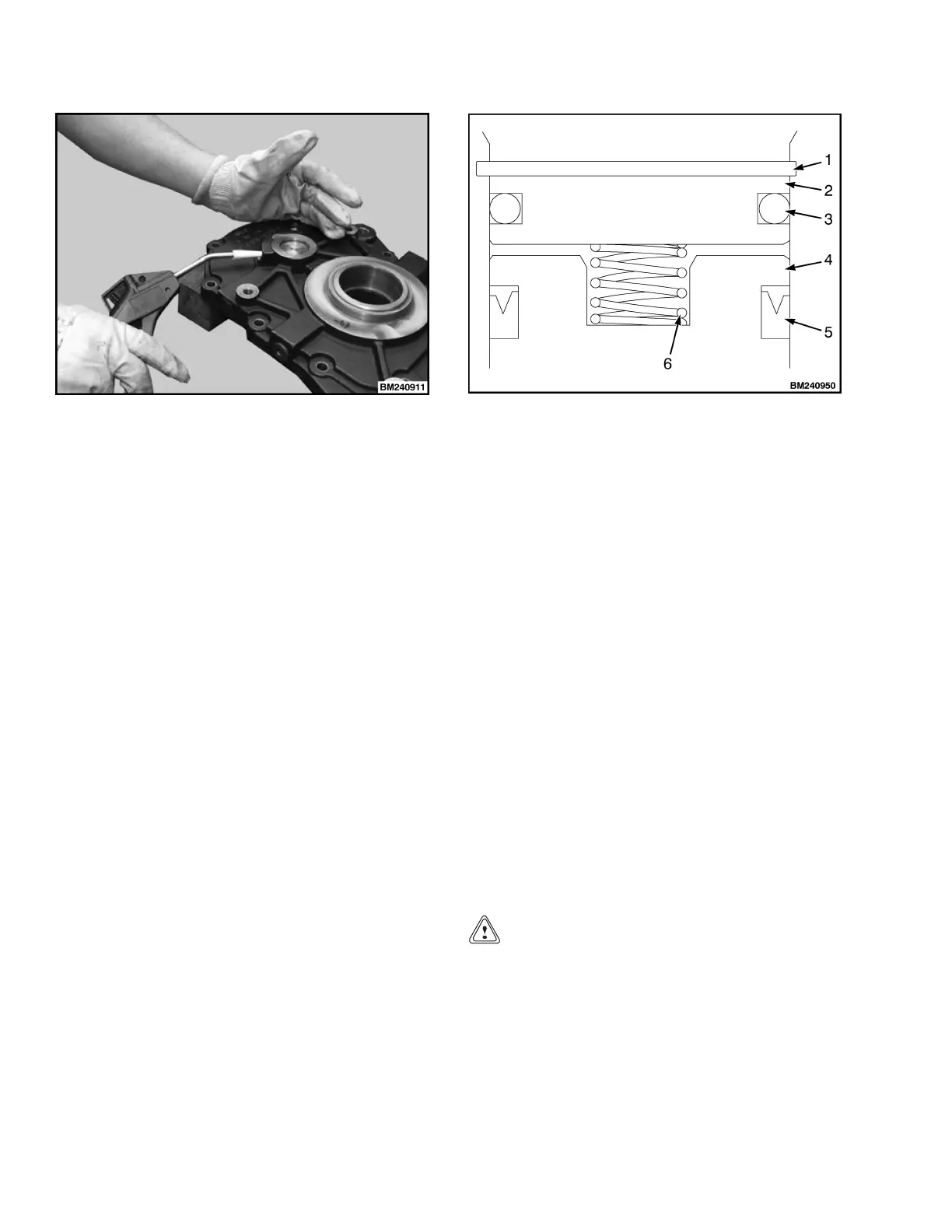

Figure 15.

Removing the Cap

5. Usingagri

nd stone, slightly bevel the end of a 7/16

x2inchrol

l pin. Allow pin to cool.

6. Carefully

position roll pin to piston. Drive roll-pin

into cavit

yofpistonwithanylonfacedhammer.

NOTE: It ma

y be helpful to apply compressed air to the

service br

ake line port (as with removing the cap) AF-

TER the pi

ston has been pulled to the top end of the

brake cyl

inder.

NOTE: Mak

e note of the piston and seal orientation dur-

ing remov

al.

7. Pull roll

-pin (and piston) from cylinder using pliers.

NOTE: Mak

e note of the cylindrical pin orientation dur-

ing remov

al.

8. Remove cy

lindrical pin from beneath piston.

9. Inspect c

ylinder walls for pits, cracks, and other

damage.

NOTE: Ins

tall the cylindrical pin in the orientation noted

during r

emoval.

10. Lightly l

ubricate cylindrical pin with multipurpose

grease a

nd install into brake cylinder as noted dur-

ing remo

val.

NOTE: An

ew brake piston and new seal should be used

when rep

airing the brake cylinder assembly. Make sure

the new p

iston and new seal are oriented as noted when

remove

d.

11. Lightl

y lubricate new piston seal with multipurpose

grease

and install in new brake piston as noted dur-

ing rem

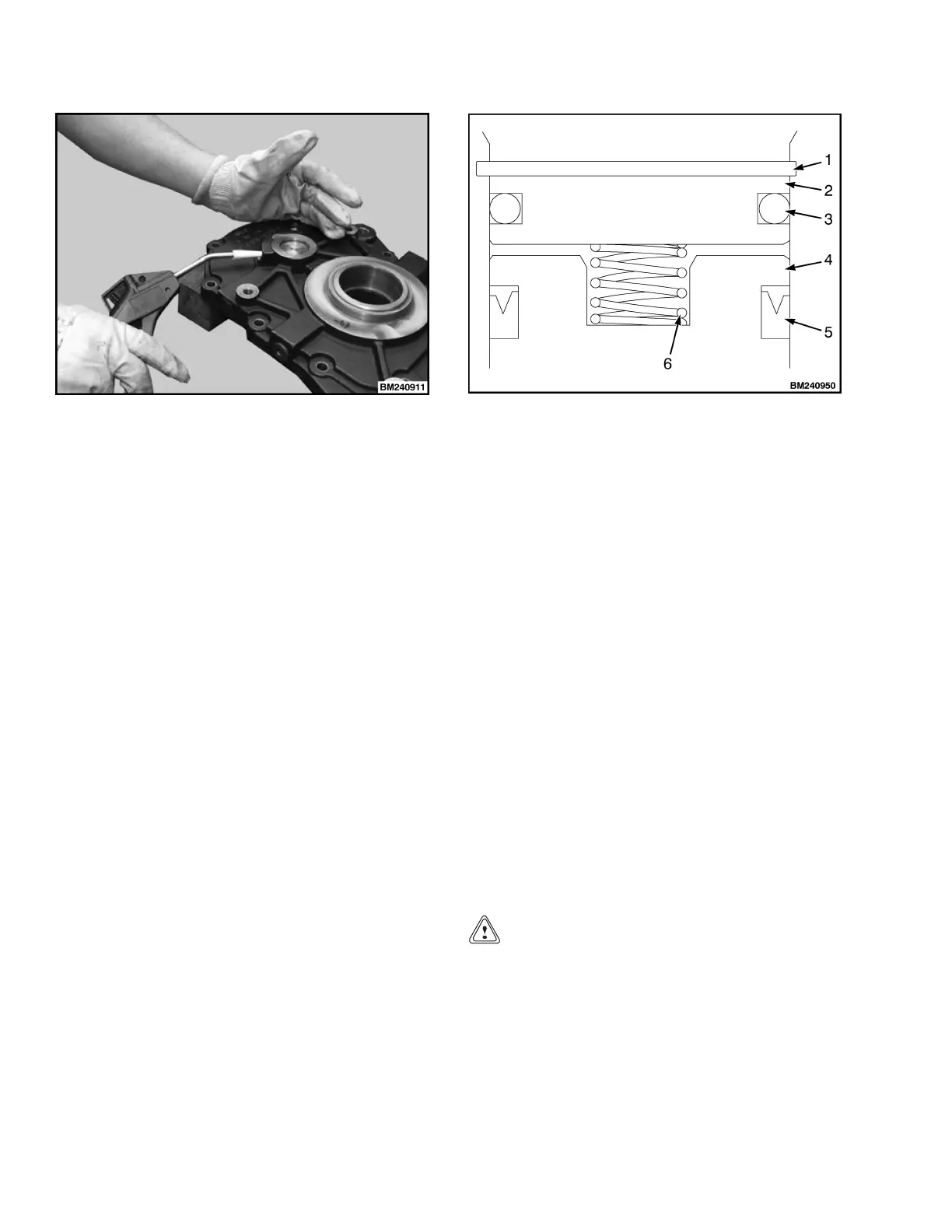

oval. See Figure 16.

1. SNAP RING

2. CAP

3. O-RING

4. PISTON

5. SEAL

6. SPRING

Figure 16. Piston Seal Orientation

12. Install new brake piston (and seal) into brake cylin-

der.

13. Place spring into cavity in piston by hand.

14. Lightly lubricate new O-ring with multipurpose

grease and install on cap as noted during removal.

NOTE: Make sure the cap is oriented as noted when

removed.

15. Install cap into brake cylinder.

16. Press cap into cylinder, to expose snap ring groove,

and install snap ring on brake piston.

NOTE: It is recommended to verify the torque on the

transaxle cover capscrews before reinstalling the trac-

tion motor. See section Cover to Housing Seal.

17. Install brake and traction motor on transaxle and

install transaxle on lift truck. See section Install

Transaxle to Frame.

CAUTION

Make sure the lift truck is blocked at the same

height as with the drive tire installed to ensure the

proper fluid level reading.

18. Check transaxle fluid level. See section Fluid Level

Check.

19. Install drive tire and tighten lugs to 170 N•m

(125 lbf ft). Test lift truck for proper operation.

12

Loading...

Loading...