Transaxle Assembly 1300 YRM 1330

REMOVE THE PARKING BRAKE AND

TRACTION MOTOR

WARNING

Cleaning solvents can be flammable and toxic and

can cause skin irritation. When using cleaning

solvents, always follow the solvent manufacturer’s

recommended safety procedures.

WARNING

The traction motor is heavy. Be sure that all lifting

devices are suitable and of adequate capacity to lift

the traction motor.

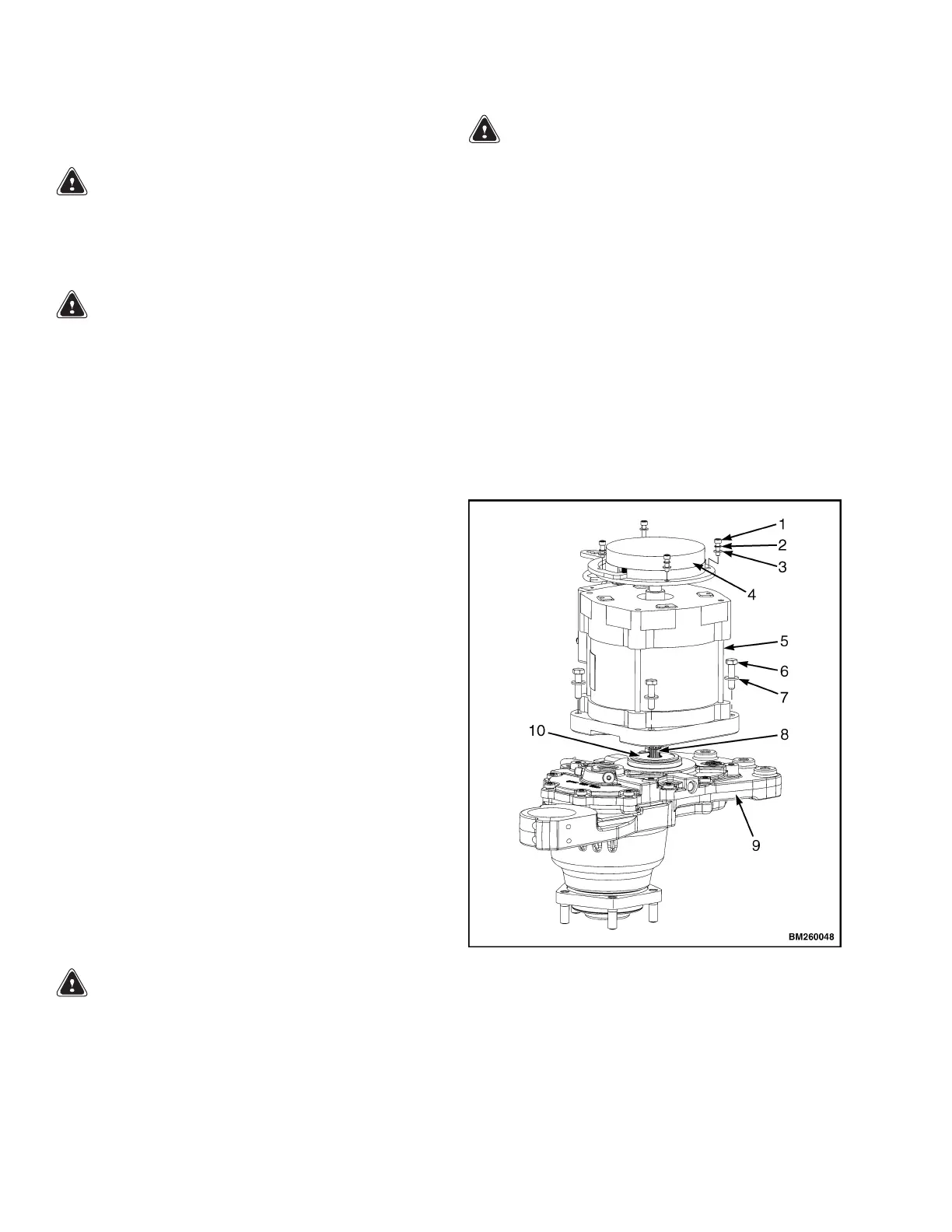

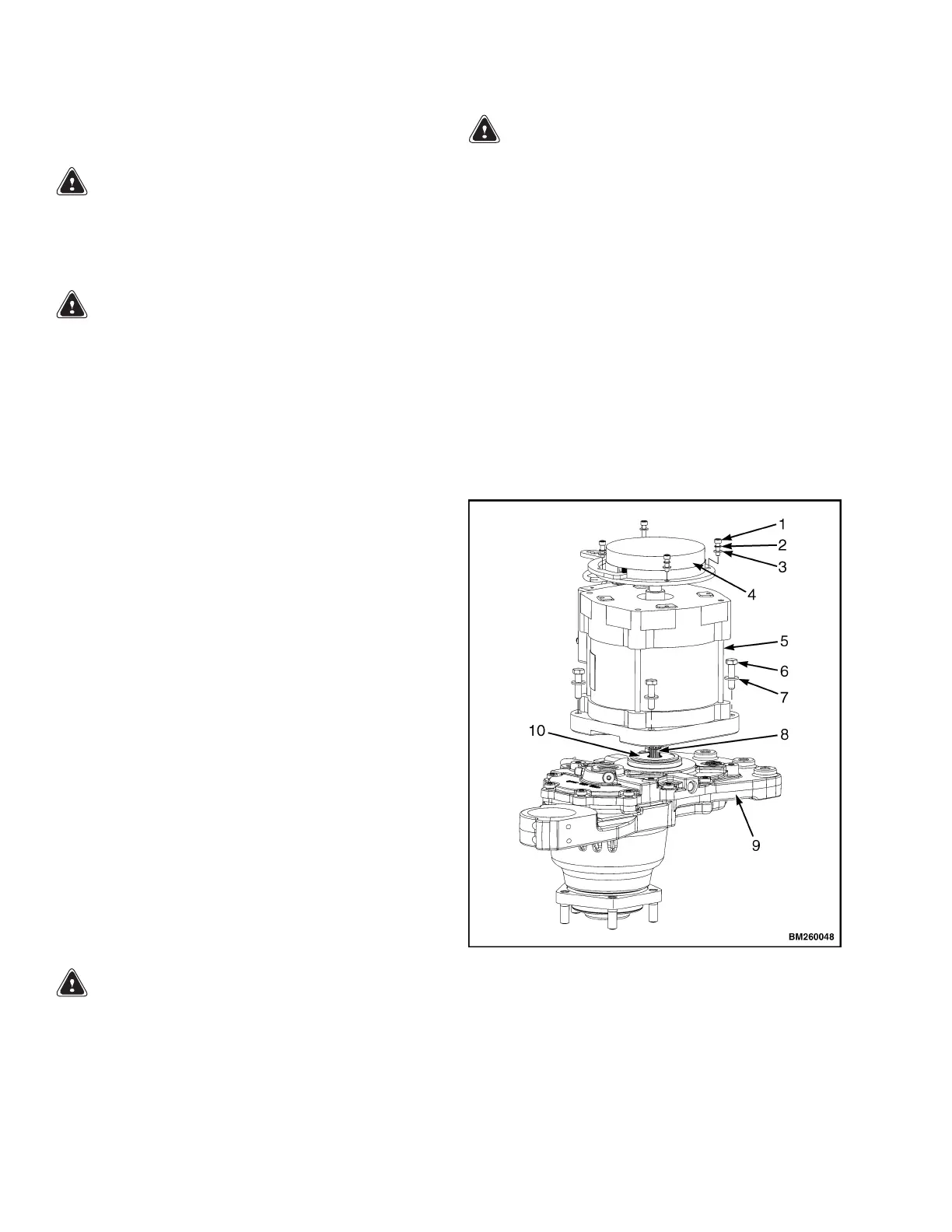

1. Position transaxle on blocks with studs down. Se-

curely support in this position.

2. Remove parking brake assembly from traction mo-

tor:

a. Remove four capscrews, lockwashers, and

washers holding brake assembly on traction

motor. See Figure 3.

b. Pry evenly on opposite sides to remove brake

assembly from brake hub. Remove brake as-

sembly by hand.

c. Remove snap ring holding brake hub on trac-

tion motor shaft. Slide hub from shaft. Remove

snap ring and woodruff key from beneath hub.

3. Remove traction motor from transaxle:

a. Install an eyebolt to traction motor shaft and

attach an overhead lifting device of adequate

capacity to eyebolt.

b. Remove four capscrews and washers mounting

traction motor to transaxle.

c. Lift traction motor from transaxle using over-

head lifting device.

INSTALL PARKING BRAKE AND

TRACTION MOTOR

WARNING

Cleaning solvents can be flammable and toxic and

can cause skin irritation. When using cleaning

solvents, always follow the solvent manufacturer’s

recommended safety procedures.

WARNING

The traction mo

torisheavy. Besurethatalllifting

devices are sui

table and of adequate capacity to lift

the traction m

otor.

1. Position tran

saxle on blocks with studs down. Se-

curely suppor

t in this position.

2. Install tract

ion motor on transaxle:

a. Install an eye

bolt to traction motor shaft and

attach an over

head lifting device of adequate

capacity to e

yebolt.

b. Lightly lubr

icate inside lip of transaxle input

shaft with mu

ltipurpose grease to ensure seal

seats proper

ly on traction motor shaft. It is not

necessary to

lubricate traction motor shaft as

it is lubrica

ted internally within the transaxle.

See Figure 4

.

1. CAPSCREW

2. LOCKW

ASHER

3. WASHER

4. PARKING BRAKE

ASSEMB

LY

5. TRACTION MOTOR

6. CAPSCREW

7. WASHE

R

8. MOTOR SHAFT

9. TRANSAXLE

10. INPUT S

EAL

Figure 3. Traction Motor and Parking Brake

4

Loading...

Loading...