1-23

SPEC

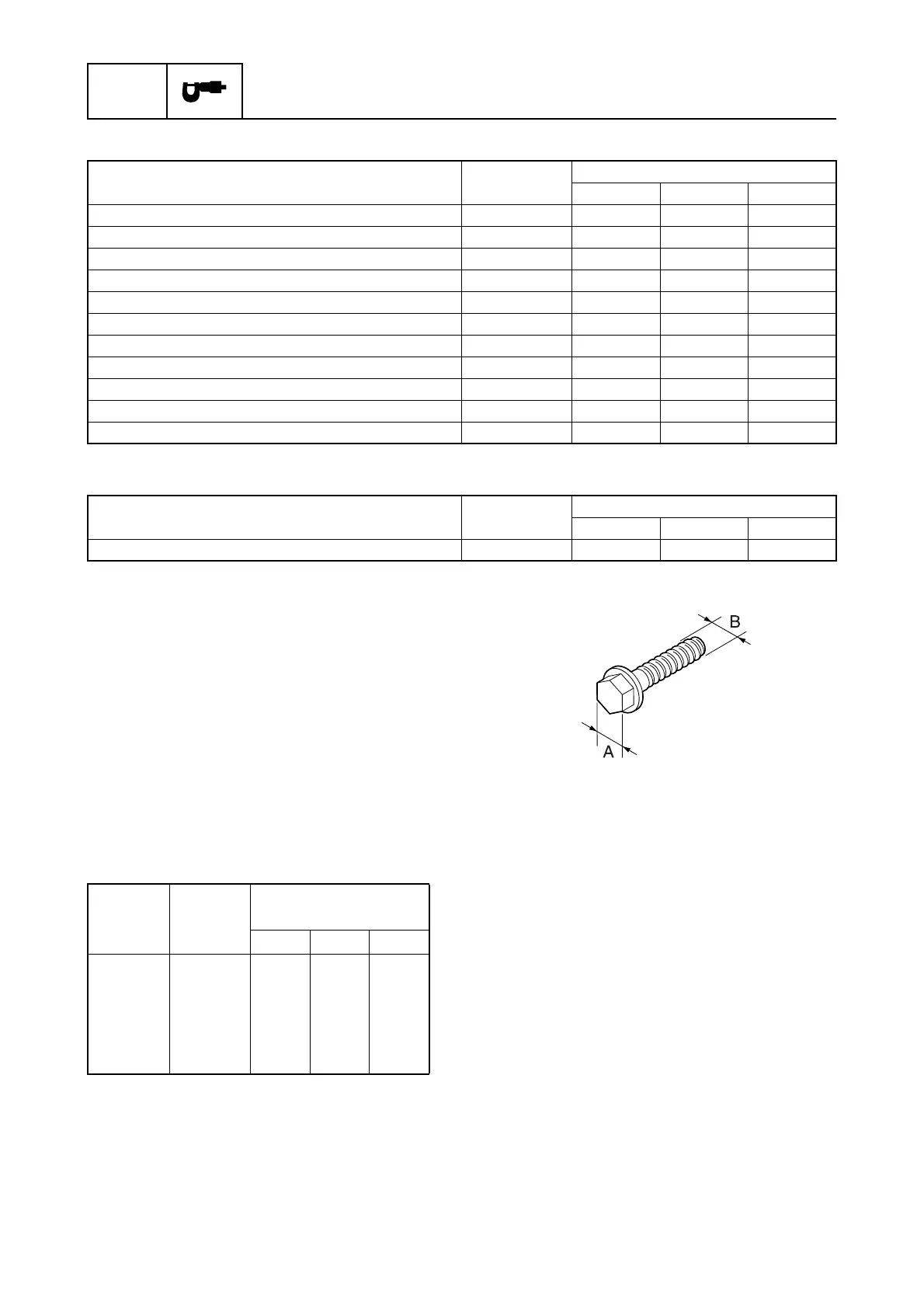

Specification

PTT unit

Optional equipment

General tightening torque

This chart indicates the tightening torques for

standard fasteners with a standard ISO

thread pitch. Tightening torque specifications

for special components and assemblies are

provided in the applicable sections of this

manual. To prevent warpage, tighten multi-

fastener assemblies in a crisscross fashion

and progressive stages until the specified

torque is reached. Unless otherwise indi-

cated, torque specifications require clean, dry

threads.

Components should be at room temperature.

Part to be tightened Screw size

Tightening torques

N·mkgf·mft·lb

Stator screw M4 2 0.2 1.5

Brush holder screw M3 1 0.1 0.7

PTT motor assembly bolt M6 7 0.7 5.2

Reservoir cap — 70.75.2

Manual valve — 30.32.2

Gear pump bolt M4 4 0.4 3.0

Valve lock screw — 60.64.4

Gear pump housing bolt M6 9 0.9 6.6

Main valve — 11 1.1 8.1

Tilt piston bolt M10 61 6.1 45.0

Tilt cylinder end screw — 90 9.0 66.4

Part to be tightened Screw size

Tightening torques

N·mkgf·mft·lb

Self-locking nut (6X4) — 37 3.7 27.3

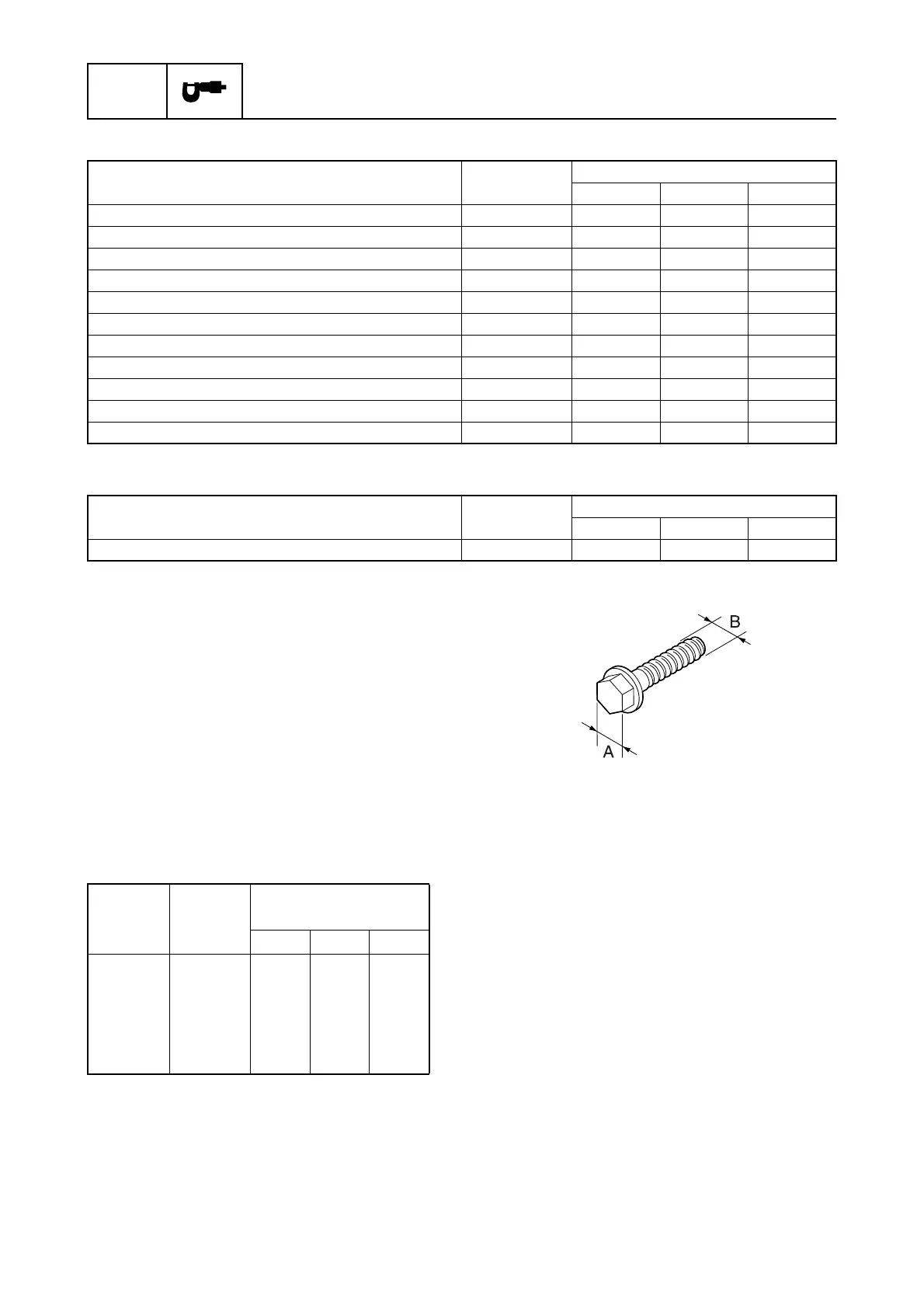

Width

across

flats (A)

Screw

size (B)

General torque

specifications

N·mkgf·mft·lb

8 mm M5 5 0.5 3.7

10 mm M6 8 0.8 5.9

12 mm M8 18 1.8 13.3

14 mm M10 36 3.6 26.6

17 mm M12 43 4.3 31.7

Loading...

Loading...