208

14. Reassemble the shifter by reversing the disassembly

procedure. Note the following during reassembly:

a. Apply sealant to the detent setscrew threads.

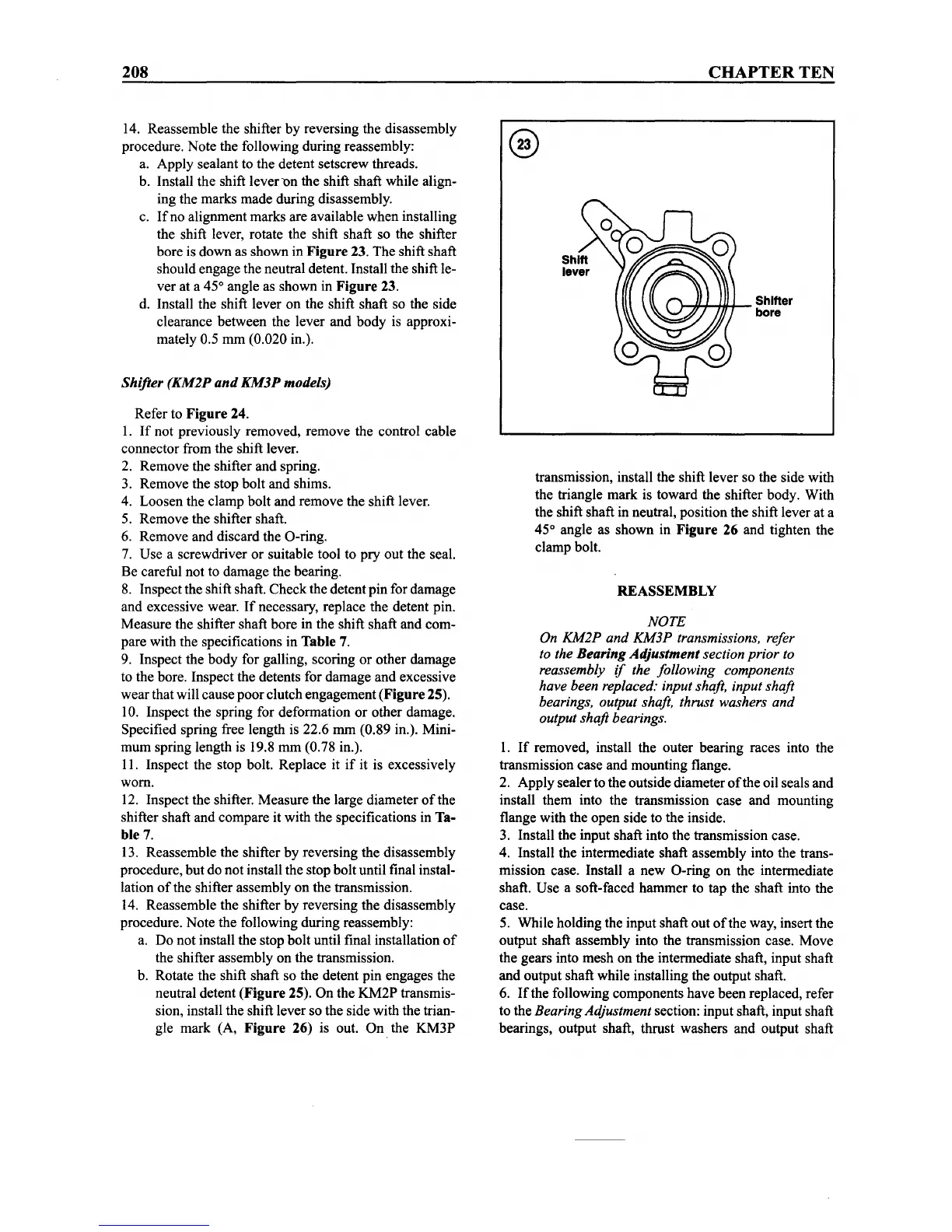

b. Install the shift lever

on

the shift shaft while align-

ing the marks made during disassembly.

c.

If

no alignment marks are available

when

installing

the shift lever, rotate the shift shaft so the shifter

bore is

down

as shown in

Figure

23. The shift shaft

should engage the neutral detent. Install the shift le-

ver at a 45° angle as shown in

Figure

23.

d. Install the shift lever on the shift shaft so the side

clearance between the lever and

body

is approxi-

mately 0.5 mm (0.020 in.).

Shifter

(KM2P

and

KM3P

models)

Refer to

Figure

24.

1.

If

not previously removed, remove the control cable

connector from the shift lever.

2. Remove the shifter and spring.

3. Remove the stop bolt and shims.

4. Loosen the clamp bolt and remove the shift lever.

5. Remove the shifter shaft.

6. Remove and discard the O-ring.

7. Use a screwdriver or suitable tool to

pry

out

the seal.

Be careful not to damage the bearing.

8. Inspectthe shift shaft.

Check

the detent pin for damage

and excessive wear.

If

necessary, replace the detent pin.

Measure the shifter shaft bore in the shift shaft and com-

pare with the specifications in

Table

7.

9. Inspect the

body

for galling, scoring or other damage

to the bore. Inspect the detents for damage and excessive

wear

that will cause

poor

clutch engagement

(Figure

25).

10. Inspect the spring for deformation or other damage.

Specified spring free length is 22.6 mm (0.89 in.). Mini-

mum

spring length is 19.8

mm

(0.78 in.).

II.

Inspect the stop bolt. Replace it

if

it is excessively

worn.

12. Inspect the shifter. Measure the large diameter

of

the

shifter shaft and compare it with the specifications in Ta-

ble 7.

13. Reassemble the shifter by reversing the disassembly

procedure, but do not install the stop bolt until final instal-

lation

of

the shifter assembly on the transmission.

14. Reassemble the shifter by reversing the disassembly

procedure. Note the following during reassembly:

a. Do not install the stop bolt until final installation

of

the shifter assembly on the transmission.

b. Rotate the shift shaft so the detent pin engages the

neutral detent

(Figure

25). On the

KM2P

transmis-

sion, install the shift lever so the side with the trian-

gle

mark

(A,

Figure

26) is out. On. the

KM3P

CHAPTER

TEN

}--''I+~'+-_

Shifter

bore

transmission, install the shift lever so the side with

the triangle mark is toward the shifter body. With

the shift shaft in neutral, position the shift lever at a

45° angle as

shown

in

Figure

26 and tighten the

clamp bolt.

REASSEMBLY

NOTE

On KM2P

and

KM3P transmissions, refer

to the

Bearing

Adjustment

section prior to

reassembly

if

the following components

have been replaced: input shaft, input shaft

bearings, output shaft, thrust washers

and

output shaft bearings.

I.

If

removed, install the outer bearing races into the

transmission case and mounting flange.

2. Apply sealerto the outside diameter

of

the oil seals and

install them into the transmission case and mounting

flange with the open side to the inside.

3. Install the input shaft into the transmission case.

4. Install the intermediate shaft assembly into the trans-

mission case. Install a

new

O-ring on the intermediate

shaft. Use a soft-faced

hammer

to tap the shaft into the

case.

5. While holding the input shaft

out

of

the way, insert the

output shaft assembly into the transmission case. Move

the gears into

mesh

on the intermediate shaft, input shaft

and output shaft while installing the output shaft.

6.

Ifthe

following components have been replaced, refer

to the

BearingAdjustment section: input shaft, input shaft

bearings, output shaft, thrust washers and output shaft

Loading...

Loading...