46

motor oil and waste haulers provide curb-

side used motor oil collection. Do not com-

bine other fluids

~vith

motor oil to be

recycled. To locate a recycler, contact the

American Petroleum Institute (API) at

wwwre

cycleoit.org.

The oil filter is a disposable spin-on type. An oil filter

wrench can be used to remove the filter, but do not use itto

install the new filter. Overtighteningthe filter may cause it

to leak.

The

installed angle

of

the engine affects oil lcvcl in the

crankcase. To assure that the oil is drained and replaced

properly, perform the following procedure with the

boat

at

rest in the water.

1. Start the engine and

wann

it to normal operating tem-

perature under load, then shut

it off.

2. Remove the dipstick

and

wipe it clean with a lint-free

cloth or paper towel.

3. Insert

the oil drain

pump

hose into the dipstick tube as

far as it

wiIIgo.

4. Insert the other pump

hose into a sealable container

large enough to hold the oil from the crankcase. Refer to

T

ab

le 3 to determinethe capacity

of

the engine crankcase.

5. Operate the pump until it has removed all

of

the oil

possible from the crankcase. Remove the pump hose from

the dipstick tube.

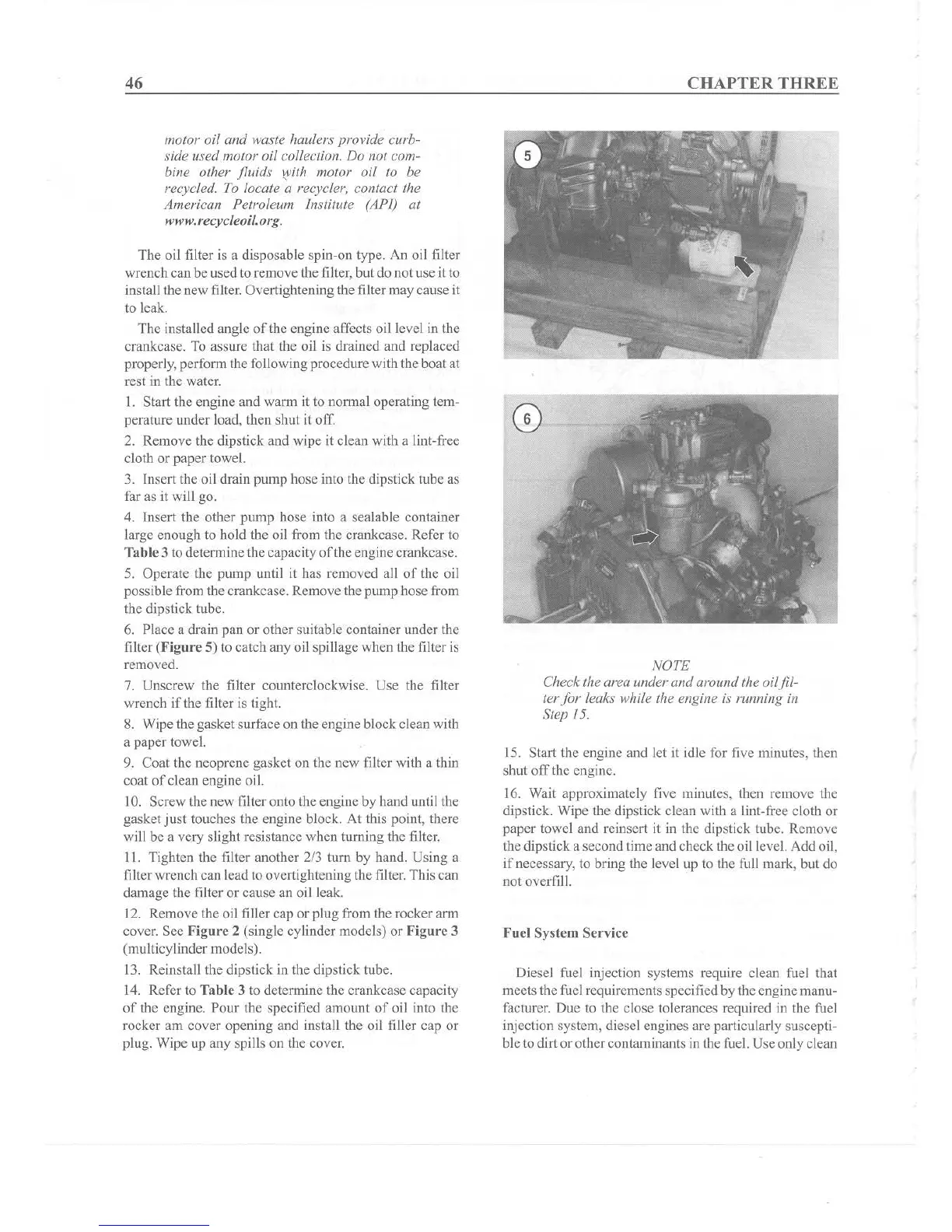

6. Place a drain pan

or

other

suitable container under the

filter (Fig

ur

e 5) to catch any oil spillage when the filter is

removed.

7. Unscrew the filter counterclockwise. Use the filter

wrench if the filter is tight.

8. Wipe the gasket surface on the engine block clean with

a paper towel.

9.

Coat

the neoprene gasket on the

new

filter with a thin

coat

of

clean engine oii.

10. Screw the

new

filter onto the engine by hand until the

gasket

just

touches the engine block. At this point, there

will be a very slight resistance when turning the filter.

I I. Tighten the filter another 2/3

tum

by hand. Using a

filter wrench can lead to overtightening the filter. This can

damage the filter or

cause

an oil leak .

12. Remove the oil filler cap or plug from the rocker

arm

cover. See Figure 2 (single cylinder models) or Fig

ure

3

(mult

icylinder models).

13. Reinstall the dipstick in the dipstick tube .

14. Refer to

Table

3 to determine the crankcase capacity

of

the engine.

Pour

the specified amount

of

oil into the

rocker am

cover

opening and install the oil filler cap or

plug. Wipe up any spills on the

cover

.

CHAPTER

THREE

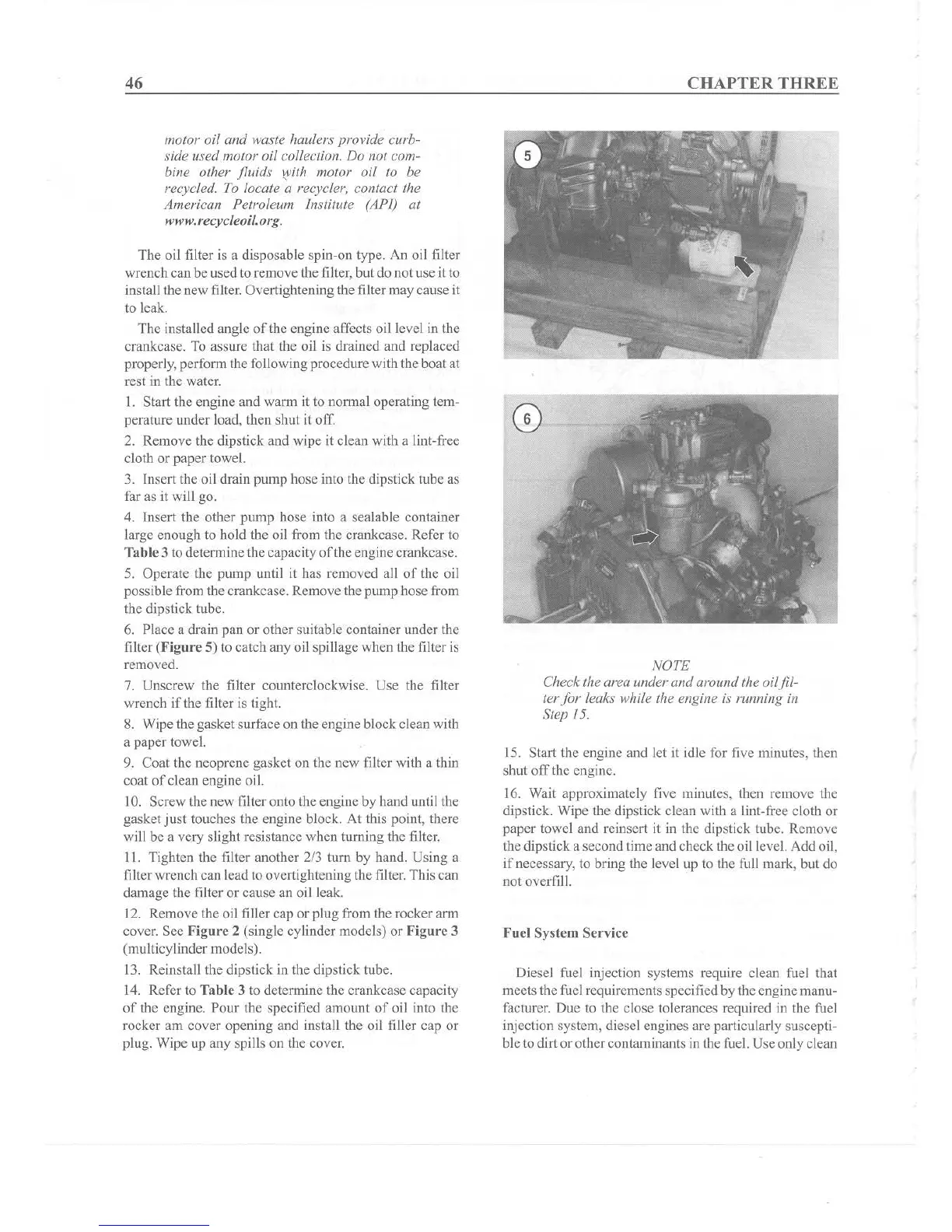

NOTE

Check the area under and around the

oiljil

-

ter

for

leaks while the engine is running in

Step /5.

IS. Start the engine and let it idle for five minutes, then

shut

off

the engine.

16. Wait approximately five minutes, then remove the

dipstick. Wipe the dipstick clean with a lint-free cloth or

paper towel and reinsert it in the dipstick tube. Remove

the dipstick a second time and check the oil

level.

Add

oil,

if

necessary, to bring the level up to the full mark, but do

net overfill.

Fuel System Serv ice

Diesel fuel injection systems require clean fuel that

meets the

fuel requirements specified by the engine manu-

facturer. Due to the close tolerances required in the fuel

injection system, diesel engines are particularly suscepti-

ble to dirt or

other

contaminants in the fuel. Use only clean

Loading...

Loading...