GENERAL INFORMATION

T

,

I

,

19

l.

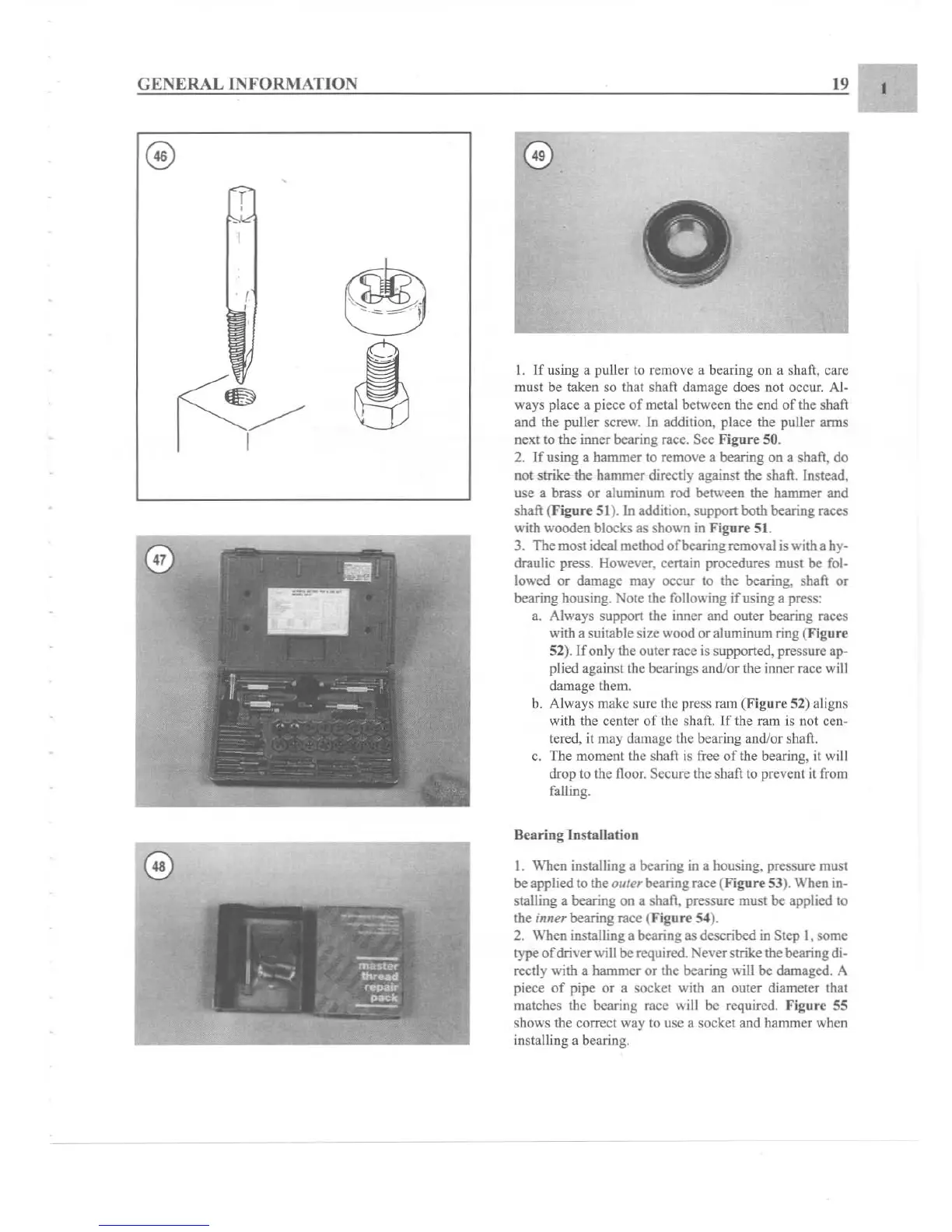

If using a puller to remove a bearing on a shaft, care

must be taken so that shaft damage does not occur. Al-

ways place a piece

of

metal between the end

of

the shaft

and the puller screw. In addition. place the puller arms

next to the inner bearing race. See

Figure

SO

.

2.

If

using a hammer to remove a bearing on a shaft. do

not strike the hamme r directly against the shaft. Instead.

use a brass or alum inum rod between the hammer and

shaft (Figure 51). In addition. support

both bearing races

with wooden blocks as shown in f igure 51.

3. The most ideal method of bearing removal is with a hy-

draulic press. However, certain procedures must

be fol-

lowed or damage may occur to the bearing, shaft or

bearing housing. Note the following if using a press:

a. Always support the inner and oute r bearing races

with a suitable size wood or aluminum ring

(Figure

52).

If

only the outer race is supported. pressure ap-

plied against the bearings and/or the inner race will

damage them.

b. Always make sure the press ram (Figure 52) aligns

with the center of the shaft. If the ram is not cen-

tered, it may damage the bearing and/or shaft.

c. The moment the shaft is free

of

the bearing, it will

drop to the floor. Secure the shaft to prevent it from

falling.

Be

aring

Installation

1. When installing a bearing in a housing. pressure must

beapplied to the outer bearing race (Figure 53). When in-

stalling a bearing on a shaft. pressure must be applied to

the

inner bearing race (Figure 54).

2. When installing a bearing as described in Step 1. some

type

of

driver willbe required. Never strike the bearing di-

rectly with a hammer or the bearing will be damaged. A

piece

of

pipe or a socket with an outer diameter that

matches the bearing race will be required.

Fig

ur

e SS

shows the correct way to use a socket and hammer when

installing a bearing.

I

Loading...

Loading...