48 Operating rhe tractor

(3)

Tire inflation

Check tires daily for damage or noticeably low

pressure.

At least every

50

hours of operation, check infla-

tion pressure with a gauge. Use an accurate gauge

having

0.1

kg/cm2

(1

psi) graduations.

If tires contain liquid ballast, use a special air-water

gauge and measure with valve stem

at

bottom.

Properly inflated tires are important to the opera-

tion

of

your tractor. The amount of air pressure

to be carried in the front and rear tires depends

upon the implement used with

the tractor and the

amount of ballast.

24051

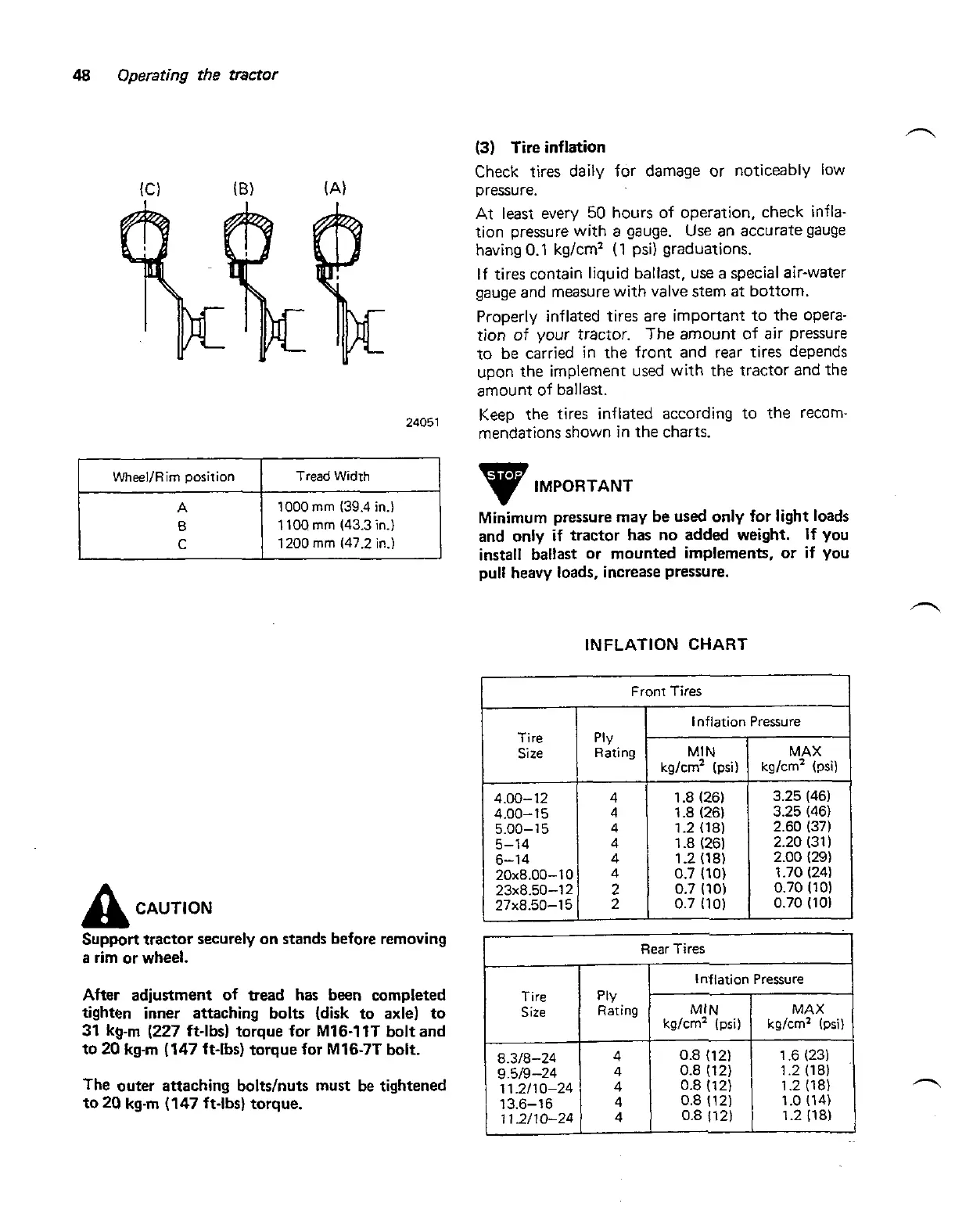

Keep the tires inflated according to the recom

mendations shown in the charts.

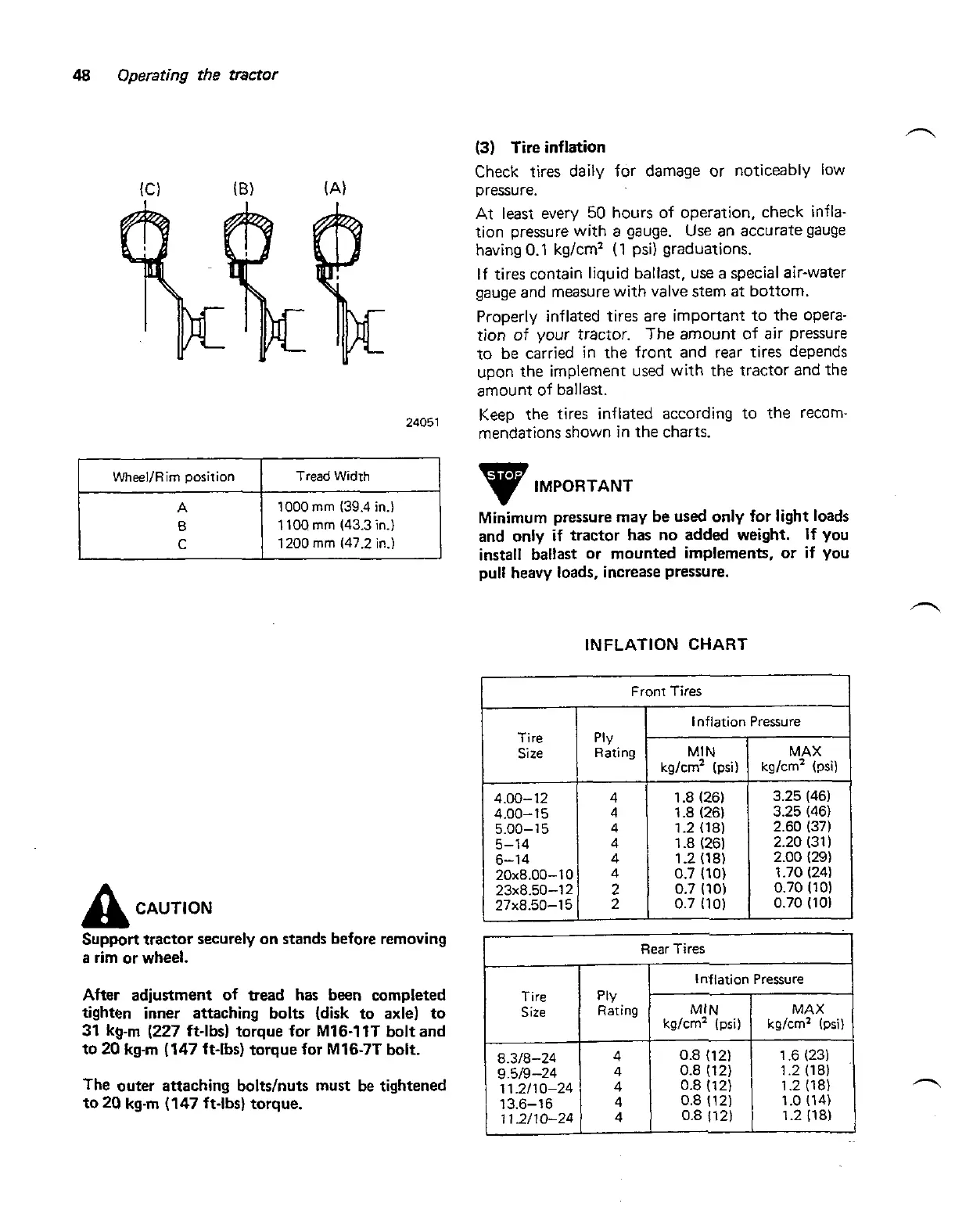

WheelIRim position Tread Width

1000

rnm

(39.4 in.)

1100 mm (43.3

in.)

1200 rnm (47.2 in.)

A

CAUTION

Support tractor securely on stands before removing

a

rim or wheel.

After adjustment of tread has been completed

tighten inner attaching bolts (disk to axle) to

31 kg-m (227 ft-lbs) torque for

M16-llT bolt and

to 20 kg-m (147 ft-lbs) torque for M16-7T bolt.

The outer attaching

boltslnuts must be tightened

to

20

kg-m (147 ft-lbs) torque.

~inimum pressure may be used only for light loads

and only if tractor has no added weight. If you

install ballast or mounted implements, or if you

pull

heavy loads, increase pressure.

INFLATION CHART

Front Tires

Tire

Size

4.00-12

4.00-15

5.00-15

5-14

6-14

20~8.00-10

23~8.50-12

27~8.50-15

ply

Rating

4

4

4

4

4

4

2

2

Inflation Pressure

MIN

kg/cm2 (psi)

1.8

(26)

1.8

(261

1.2 (181

1.8 (26)

1.2 (181

0.7 (10)

0.7 (101

0.7 (10)

Rear Tires

MAX

kg/cm2

(psi)

3.25 (46)

3.25 (461

2.60 (371

2.20 (31

I

2.00 (29)

1.70 (24)

0.70 (101

0.70 (101

Tire

Size

8.318-24

9.519-24

11.2110-24

13.6-16

1

1.211 0-24

ply

Rating

4

4

4

4

4

Inflation Pressure

MIN

kg/cm2

(psi)

0.8 (12)

0.8 (121

0.8 (12)

0.8 (121

0.8 (121

MAX

kg/cm2 (psi)

1.6 (23)

1.2 (181

1.2 (18)

1.0 114)

1.2 (181

Loading...

Loading...