5292154-UIM-A-0317

12 Johnson Controls Unitary Products

Dry coil conditions only, tested without filters.

For optimal performance, external static pressures of 0.2" to 0.5" are recom-

mended. Applications above 0.5" are not recommended.

Dry coil conditions only, tested without filters.

For optimal performance, external static pressures of 0.2" to 0.5" are recom-

mended. Applications above 0.5" are not recommended.

SECTION XI: INSTALLATION

VERIFICATION

Prior to and during the accomplishment of the installation procedures,

verify all tasks are accomplished as illustrated in Figures 4 - 19.

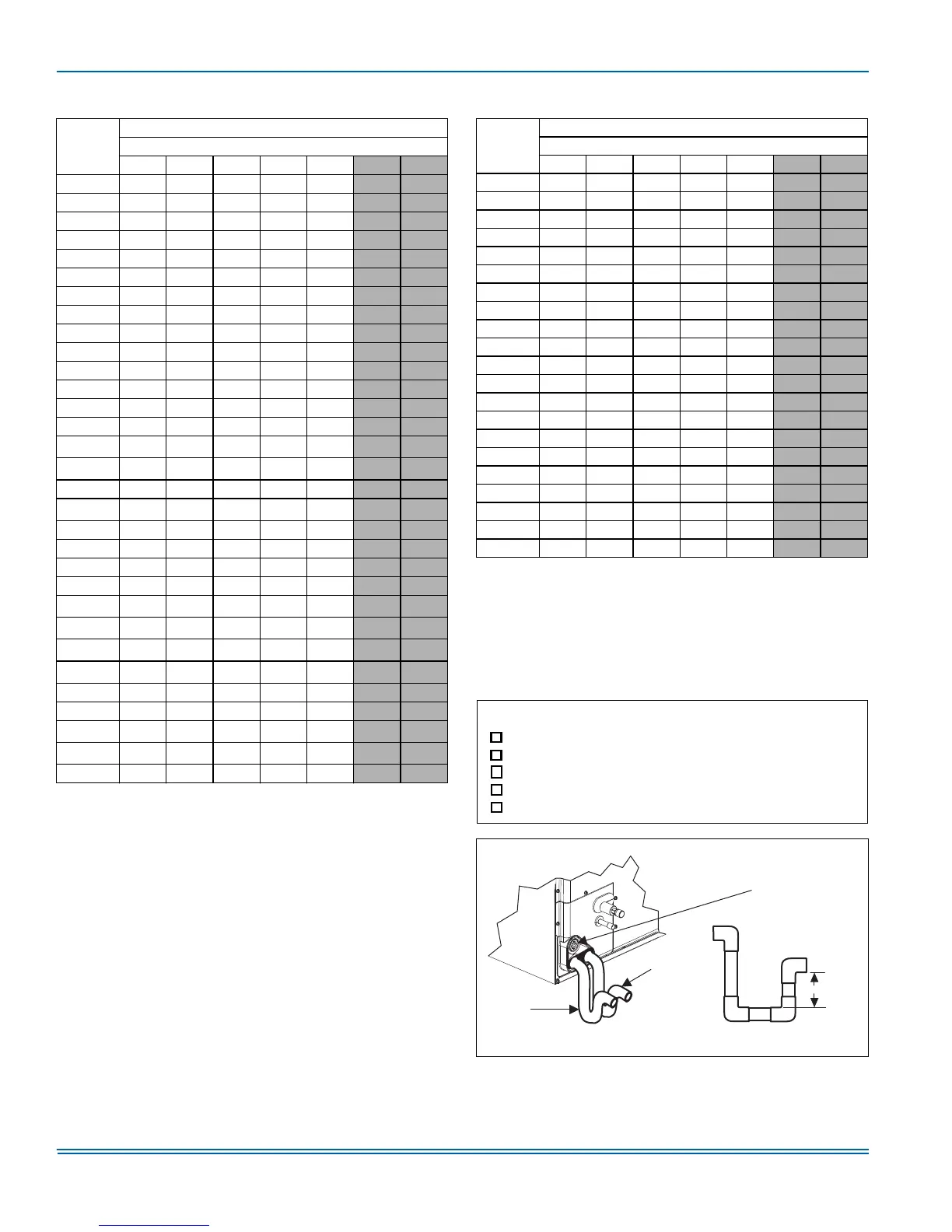

TABLE 4:

Air Flow Data - Static Pressure Drop for CM Models

Coil

1

Size

1. Asterisk # denotes coils only available with Factory Mount EEV.

CFM @ Static Pressure Drop - IWG

(Based on dry coil)

0.1 0.2 0.3 0.4 0.5 0.6 0.7

CM18A 500 700 840 997 1115 1221 1319

CM18B 670 960 1180 1340 1498 1641 1773

CM24A 490 710 850 980 1096 1200 1296

CM24B 760 1050 1330 1520 1699 1862 2011

CM24C 910 1330 1640 1820 2035 2229 2408

CM25B 710 1020 1210 1420 1588 1739 1878

CM30A 520 750 950 1040 1163 1274 1376

CM30B 670 1000 1230 1340 1498 1641 1773

CM30C 970 1410 1710 1940 2169 2376 2566

CM30D 1180 1720 2100 2360 2639 2890 3122

CM36A 520 740 920 1040 1163 1274 1376

CM36B 710 1020 1210 1420 1588 1739 1878

CM36C 980 1420 1690 1960 2191 2400 2593

CM36D 1210 1750 2150 2420 2706 2964 3201

CM37B

#

710 1020 1210 1420 1588 1739 1878

CM37C

#

980 1420 1690 1960 2191 2400 2593

CM38B TBD TBD TBD TBD TBD

TBD TBD

CM38C

#

690 1150 1420 1630 1820 1990 2150

CM42C 970 1420 1750 1940 2169

2376 2566

CM42D 1190 1730 2130 2380 2661 2915 3148

CM48C 970 1450 1910 1940 2169 2376 2566

CM48D 1250 1820 2250 2500 2795 3062 3307

CM49C

#

690 1150 1420 1630 1820 1990 2150

CM49D

#

970 1410 1740 2050 2290 2510 2710

CM50C

#

990 1440 1700 1950 2180 2390 2580

CM50D

#

940 1470 1890 2170 2430 2660 2870

CM60C 910 1551 1930 1820 2035

2229 2408

CM60D 1220 1730 2140 2440 2728 2988 3228

CM61C

#

990 1440 1700 1950 2180 2390 2580

CM61D

#

940 1470 1890 2220 2490 2720 2940

CM64D 970 1540 1800 1940 2169

2376 2566

TABLE 5:

Air Flow Data - Static Pressure Drop for CF Models

Coil

Size

CFM @ Static Pressure Drop - IWG

(Based on dry coil)

0.1 0.2 0.3 0.4 0.5

0.6 0.7

CF18A 515 720 870 1030 1152

1261 1363

CF18B 700 1000 1220 1400 1565

1715 1852

CF24A 500 730 880 1000 1118

1225 1323

CF24B 780 1090 1380 1560 1744

1911 2064

CF24C 950 1380 1700 1900 2124

2327 2513

CF30A 540 780 990 1080 1207

1323 1429

CF30B 690 1040 1280 1380 1543

1690 1826

CF30C 1000 1470 1780 2000 2236

2449 2646

CF30D 1230 1790 2180 2460 2750

3013 3254

CF36A 540 770 960 1080 1207

1323 1429

CF36B 740 1060 1250 1480 1655

1813 1958

CF36C 1020 1470 1260 2040 2281

2498 2699

CF36D 1250 1820 2330 2500 2795

3062 3307

CF42B 750 1100 1370 1500 1677

1837 1984

CF42C 1010 1470 1810 2020 2258

2474 2672

CF42D 1240 1790 2210 2480 2773

3037 3281

CF48C 1010 1500 1980 2020 2258

2474 2672

CF48D 1300 1890 2340 2600 2907

3184 3439

CF60C 950 1600 2000 1900 2124

2327 2513

CF60D 1270 1800 2220 2540 2840

3111 3360

CF64D 1010 1590 1870 2020 2258

2474 2672

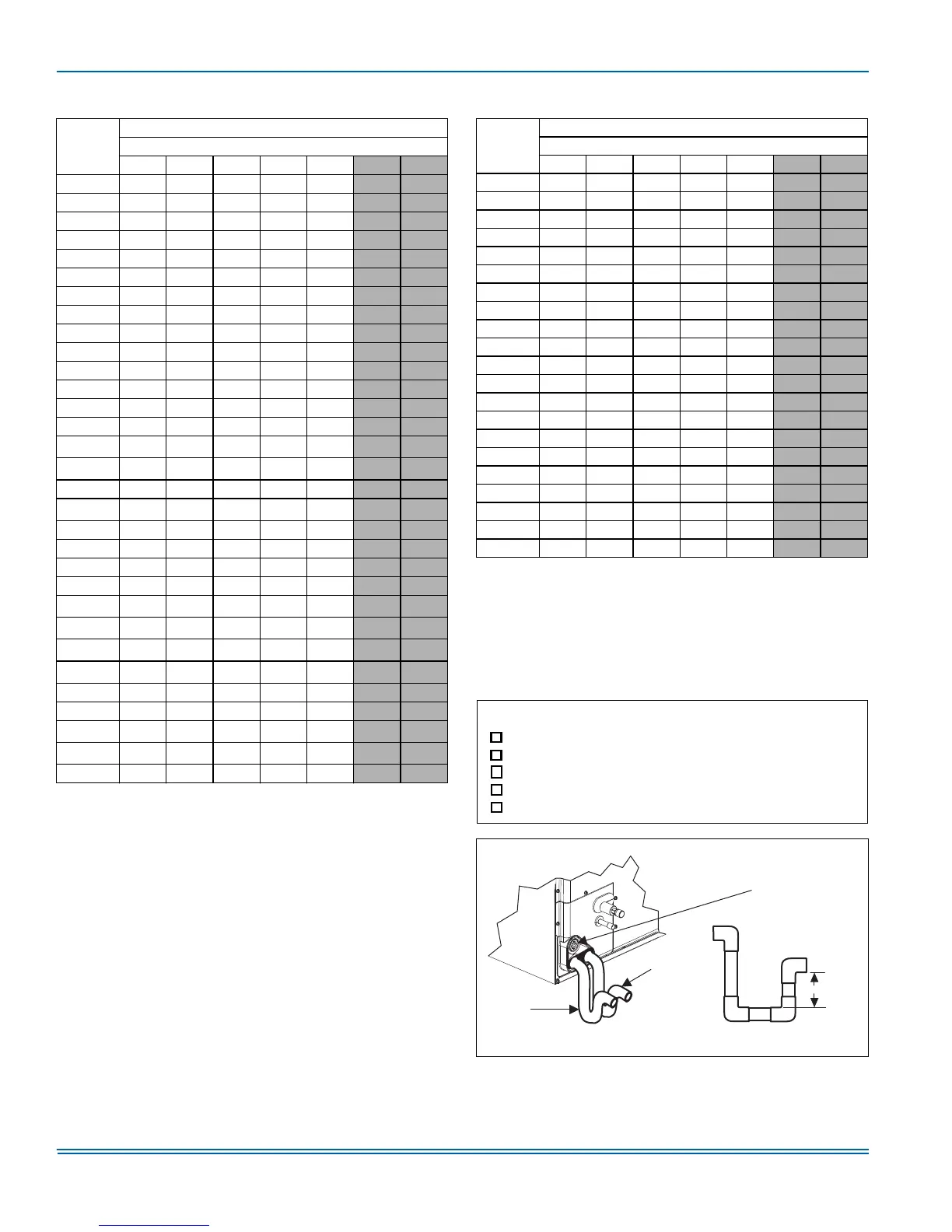

FIGURE 24: Drain Traps

THERMAL EXPANSION VALVE (TXV) CHECK LIST

Is coil metering device installed correctly?

Was correct TXV installed per the outdoor unit Technical Guide?

Is TXV temperature bulb positioned correctly?

Is TXV temperature bulb insulated?

Is equalizer line connected?

3” MINIMUM

HANDMADE TRAP

PREMADE TRAPS

SECONDARY

PRIMARY

WERE THE PRIMARY AND SECONDARY DRAINS TRAPPED CORRECTLY?

A0272-001

PLUG

(UNUSED

SECONDARY

DRAIN)

Loading...

Loading...