FORM 160.73-PW1(405)

11

YORK INTERNATIONAL

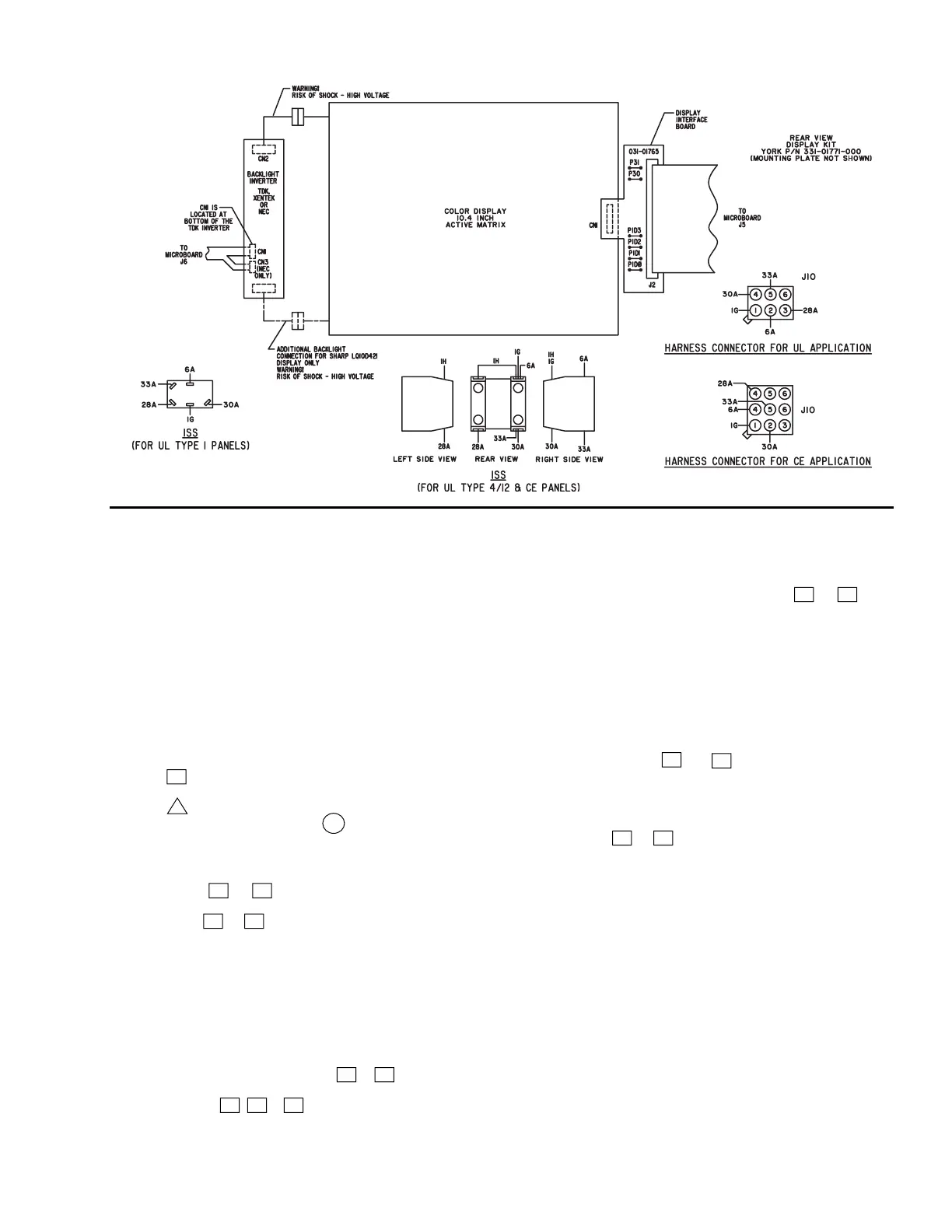

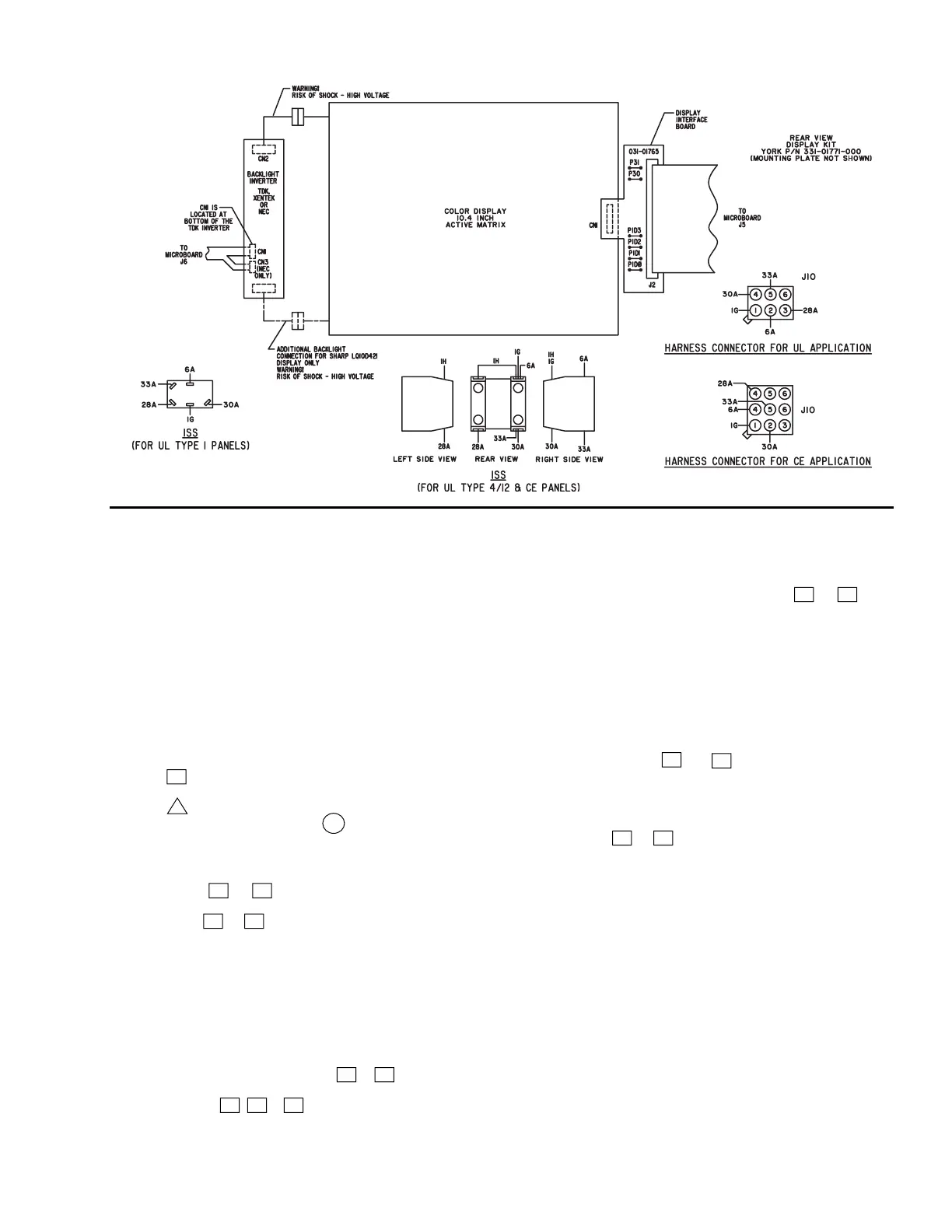

FIG. 5 – DISPLAY INTERFACE BOARD

NOTES:

1. This wiring diagram describes the standard elec tron ic

con trol scheme for use with an electromechanical start er.

For details of standard modifi cations, refer to Product

Form 160.54-PW7.

2. Field wiring to be in accordance with the National

Elec tri cal Code as well as all other applicable codes and

spec i fi ca tions. See Product Form 160.54-PW7 for fi eld

wiring con nec tions.

3. Numbers along the left side of diagram are line iden ti -

fi ca tion numbers. The numbers along the right side in di cate

the line num ber location of relay contacts. An un der lined

con tact lo ca tion signifi es a normally closed con tact.

4. Main control panel Class 1 fi eld wiring terminal con-

nec tion points are indicated by numbers within a rect an gle,

i.e. 15 . Main con trol panel factory wiring terminal con-

nec tion points are in di cat ed by numbers within a tri an gle,

i.e. 5 . Com po nent terminal markings are in di cat ed by

num bers within a circle, i.e. C1 . Num bers ad ja cent to

cir cuit lines are the cir cuit iden ti fi ca tion num bers.

5. To cycle unit on and off automatically with contacts

oth er than those shown, install a cycling device between

ter mi nals 1 & 13 (line 37) (see note 9). If a cycling

device is installed, jumper must be removed between

ter mi nals 1 & 13 .

6. Compressor motor starter with starter interlock con tacts

(rat ed 0.5 to 1.0 amp @ 24 volts A.C.) must be per Form

160.45-PA5.1. Control panel shall be grounded.

7. Units installed in Canada must have a fi eld supplied CSA

approved 30 amp disconnect switch and a 20 amp dual

element fuse mounted external to control panel for 115

volt control supply.

8. To stop unit and not permit it to start again, install a

stop device between terminals 1 & 8 (Line 33) (see

note 9). A re mote start-stop switch may be connected

to ter mi nals 1 , 7 & 8 (Lines 32 & 33) (see note 9).

Remote start-stop switch (Line 32) is op er a tive only in

the “re mote” op er at ing mode.

9. Device contact rating to be 5 milliamperes @ 115 volts

A.C.

11. Contact rating is 5 Amps resistive @ 120 volts A.C. or

240 volts A.C.

13. To check motor rotation on initial start-up, install

mo men tary switch between terminals 24 & 25 (line

41). De press start switch. After approx. 30 seconds, jog

mo tor with mo men tary switch. When proper rotation is

ob tained, replace mo men tary switch with jumper. Switch

must have a min i mum con tact rat ing of 2 FLA., 10 LRA

at 115 Volts A.C.

14. Motor overload (CM) is set to trip at 105% FLA. During

mo men tary power interruption (power fault), contact

opens for 1 sec ond.

15. For high and low voltage units, the factory supplied

jump er be tween 15 & 53 must be removed when

elec tro me chan i cal start er overloads and/or safety de vic es

are used. For high voltage (2300-4160) UL and CUL ap-

proved units only, elec tro me chan i cal com pres sor motor

starter over loads (nor mal ly closed) must be con nect ed

be tween 15 & 53 .

16. Contact rating is 5 Amps resistive @ 250 Volts A.C. &

30 Volts D.C., 2 Amp inductive (.4 PF) @ 250 Volts A.C.

& 30 Volts D.C.

17. Each 115VAC fi eld-connected inductive load: i.e. relay

coil, mo tor starter coil, etc., shall have a transient sup-

pres sor wired in parallel with its coil, physically located

at the coil. Spare tran sient suppressors and control cir cuit

fuses are sup plied in a bag attached to green ground

screw in lower left corner of control panel.

18. For units with fl ash miniature card software version

C.MLM.01.00 through C.MLM.01.03 the condenser

water pump should be wired to terminal 164 of TB2

instead of terminal 151, and the wire from terminal 22 of

TB5 to terminal 150 TB2 shall not be installed. For soft-

ware version C.MLM.01.04 and higher, the condenser

pump connection should be as shown in the fi gure.

19. Resistor for use with Belimo actuator. Remove resis-

tor if hot gas actuator is a Dodge Engineering, Bray or

Landis-Staefa actuator.

LD08956

DISPLAY INTERFACE BOARD

Loading...

Loading...