JOHNSON CONTROLS

37

SECTION 4 – INSTALLATION

FORM 150.72-ICOM6

ISSUE DATE: 12/29/2017

4

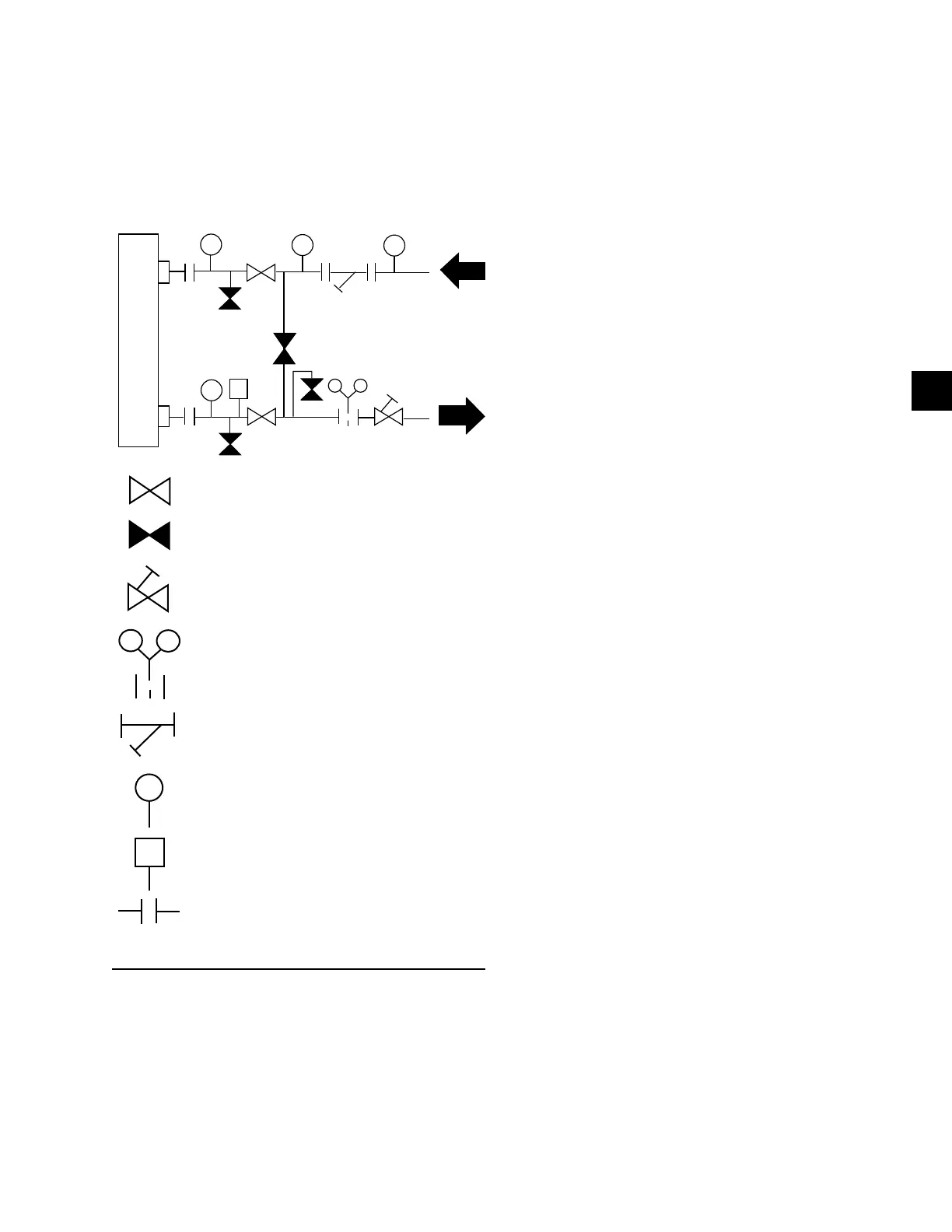

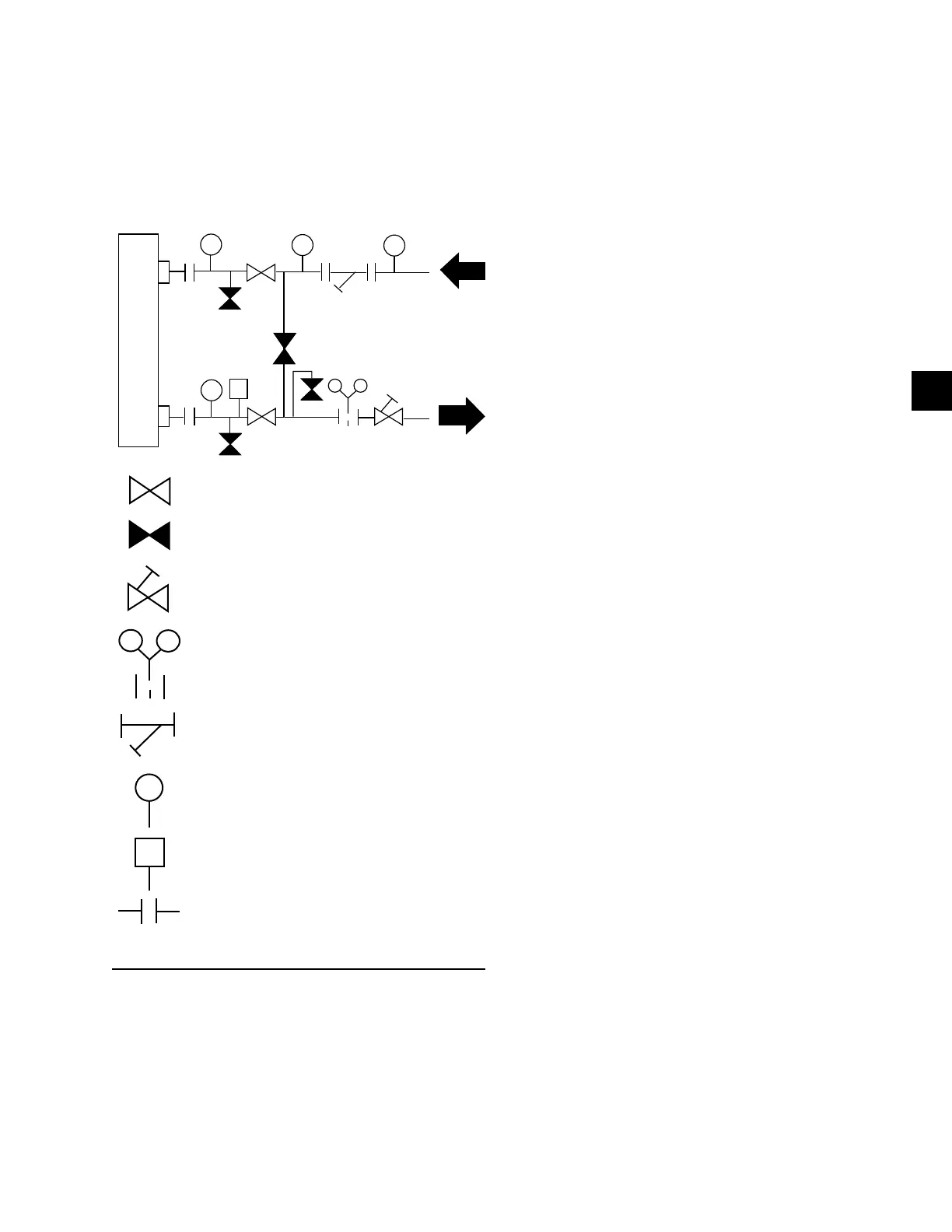

PIPEWORK ARRANGEMENT

The following are suggested pipework arrangements

for single unit installations, for multiple unit installa-

tions, each unit should be piped as shown.

Recommendations of the Building Services Re-

search Association.

B

P

H

X

LD06596a

ISOLATING VALVE - NORMALLY OPEN

ISOLATING VALVE - NORMALLY CLOSED

FLOW REGULATING VALVE

FLOW MEASUREMENT DEVICE

STRAINER

PRESSURE TAPPING

FLOW SWITCH

FLANGED CONNECTION

LD06597A

FIGURE 8 - CHILLED LIQUID SYSTEM

Fan Discharge Ducting

The following duct work recommendations are intend-

ed to ensure satisfactory operation of the unit. Failure

to follow these recommendations could cause damage

to the unit, or loss of performance, and may invalidate

the warranty.

When ducting is to be fitted to the fan discharge it is

recommended that the duct should be the same cross-

sectional area as the fan outlet and straight for at least

three feet (1 meter) to obtain static regain from the fan.

Duct work should be suspended with flexible hang-

ers to prevent noise and vibration being transmitted to

the structure. A flexible joint is also recommended be-

tween the duct attached to the fan and the next section

for the same reason. Flexible connectors should not be

allowed to concertina.

The unit is not designed to take structural loading. No

significant amount of weight should be allowed to

rest on the fan outlet flange, deck assemblies or con-

denser coil module. No more than 3 feet (1 meter) of

light construction duct work should be supported by

the unit. Where cross winds may occur, any duct work

must be supported to prevent side loading on the unit.

If the ducts from two or more fans are to be combined

into a common duct, back-flow dampers should be fit-

ted in the individual fan ducts. This will prevent re-

circulation of air when only one of the fans is running.

Units are supplied with outlet guards for safety and to

prevent damage to the fan blades. If these guards are

removed to fit duct work, adequate alternative precau-

tions must be taken to ensure persons cannot be harmed

or put at risk from rotating fan blades.

WIRING

Liquid Chillers are shipped with all factory-mounted

controls wired for operation.

Field Wiring – Power wiring must be provided

through a fused disconnect switch to the unit terminals

(or optional molded disconnect switch) in accordance

with N.E.C. or local code requirements. Minimum cir-

cuit ampacity and maximum dual element fuse size are

given in the Electrical Data tables.

Copper power wiring only should be used for supply-

ing power to the chiller. This is recommended to avoid

safety and reliability issues resulting from connection

failure at the power connections to the chiller. Alumi-

num wiring is not recommended due to thermal char-

acteristics that may cause loose terminations result-

ing from the contraction and expansion of the wiring.

Aluminum oxide may also build up at the termination

causing hot spots and eventual failure. If aluminum

wiring is used to supply power to the chiller, AL-CU

compression fittings should be used to transition from

Loading...

Loading...