B

C

A

E

D

B

C

D

A

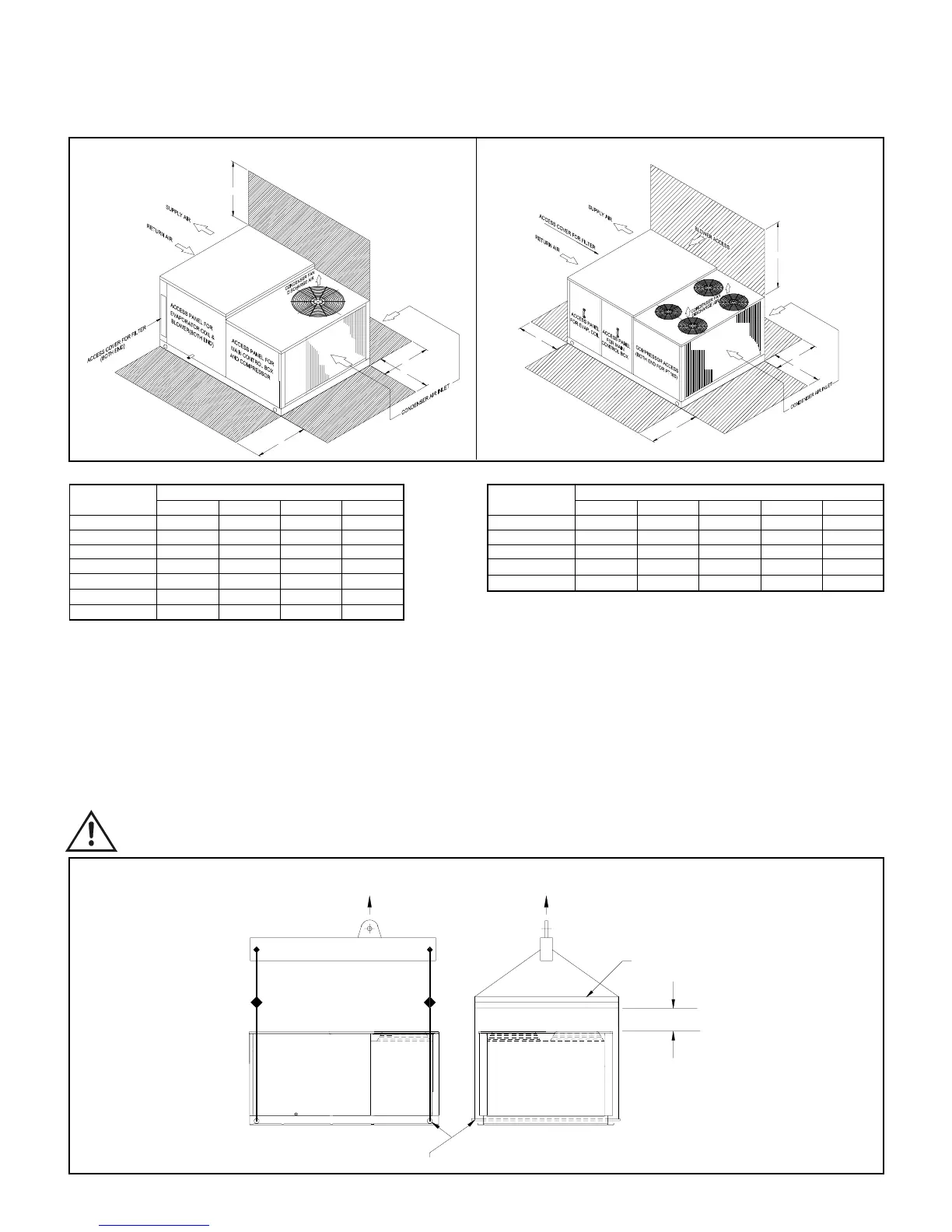

SPREADER BAR

NOMINAL PIPE THRU UNIT FOR SLINGS TO AVOID BASE DAMAGE.

END

PROPER CLEARANCE TO BE

PROVIDED.

COMPRESSOR

LIFT

LIFT

2. PIPE DIA 2" FOR PT090 TO PT360 MODELS

1 .PIPE DIA 1 1/2" FOR PT036 TO PT075 MODELS

Note:

SERVICE CLEARANCE

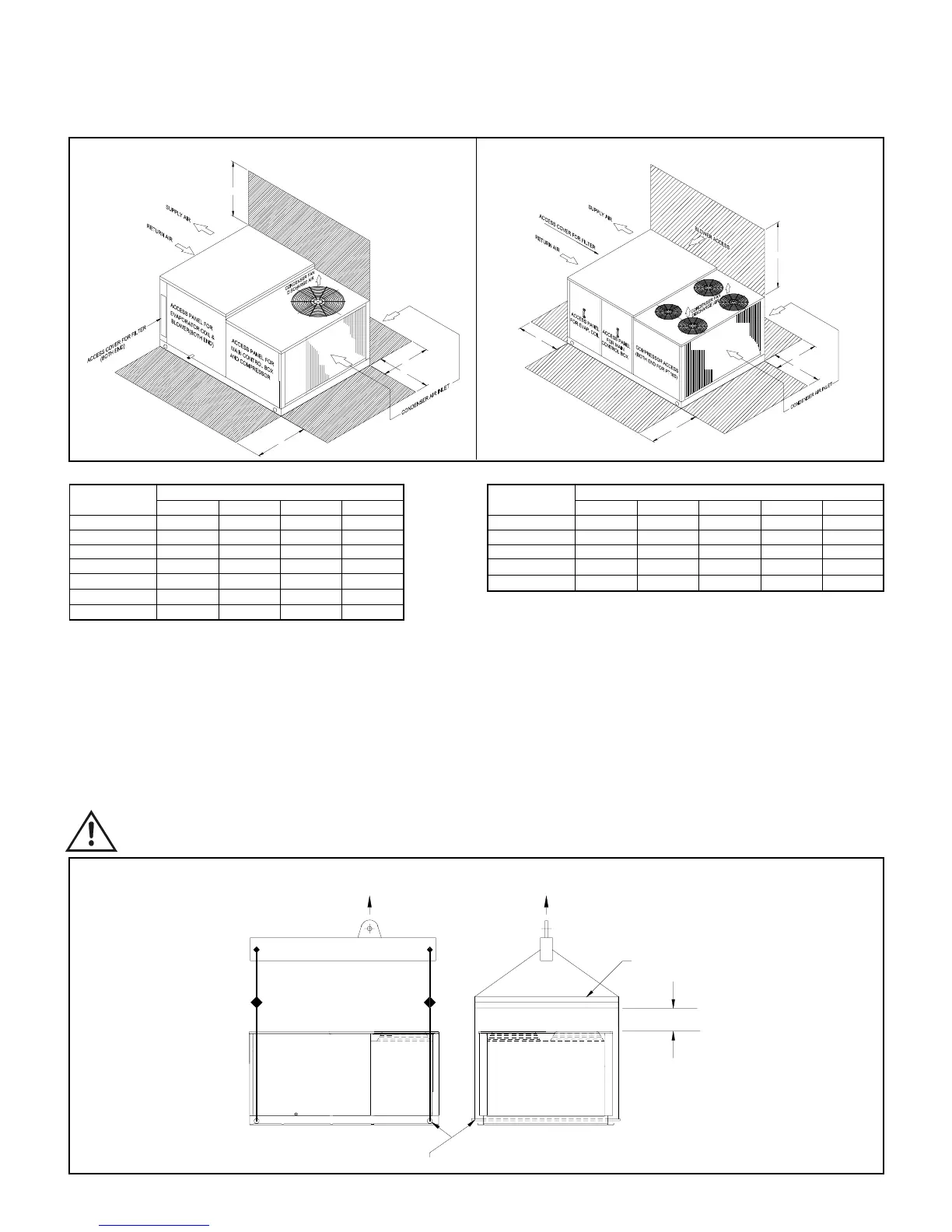

MODEL DIMENSIONS

NUMBER A B C D

PS036 85 105 85 150

PS048 85 105 85 150

PS060 85 105 85 150

PS075 90 105 90 200

PS090 90 105 90 200

PS100 90 105 90 200

PS120 90 105 90 200

NOTE: All dimensions are in cm.

A :Clearance dimension from condenser coil

B :Clearance dimension from compressor, control box, blower, evaporator coil & filter

C :Clearance dimension from condenser coil & filter

D :Clearance dimension over the condenser fan

MODEL DIMENSIONS

NUMBER A B C D E

PS180 120 120 115 250 90

PS215 120 120 115 250 90

PS240 120 120 115 250 90

PS300 120 120 115 250 90

PS360 120 120 115 250 90

A : Clearance dimension from condenser coil

B : Clearance dimension from compressor, control box & evaporator coil

C : Clearance dimension from condenser coil & blower

D : Clearance dimension over the condenser fan

E : Clearance dimension from filter access panel

MODELS: PS036 - PS120

MODELS: PS180 - PS360

ATTENTION TO RIGGERS

• Insert 2" nominal pipe through holes in the base rail as shown in the figure below for slings.

• Holes in base rail are centered around the unit center of gravity.

• Use wooden pallet or spreader bar when rigging, to prevent the slings from damaging the unit.

• Rollers may be used to move the unit on the roof or ground.

CAUTION: All panels should be in place when rigging.

RIGGING INSTRUCTIONS

MODELS: PS036 - PS360

NOTE: Only two condenser fans for models PS180 - PS240.

5

Loading...

Loading...