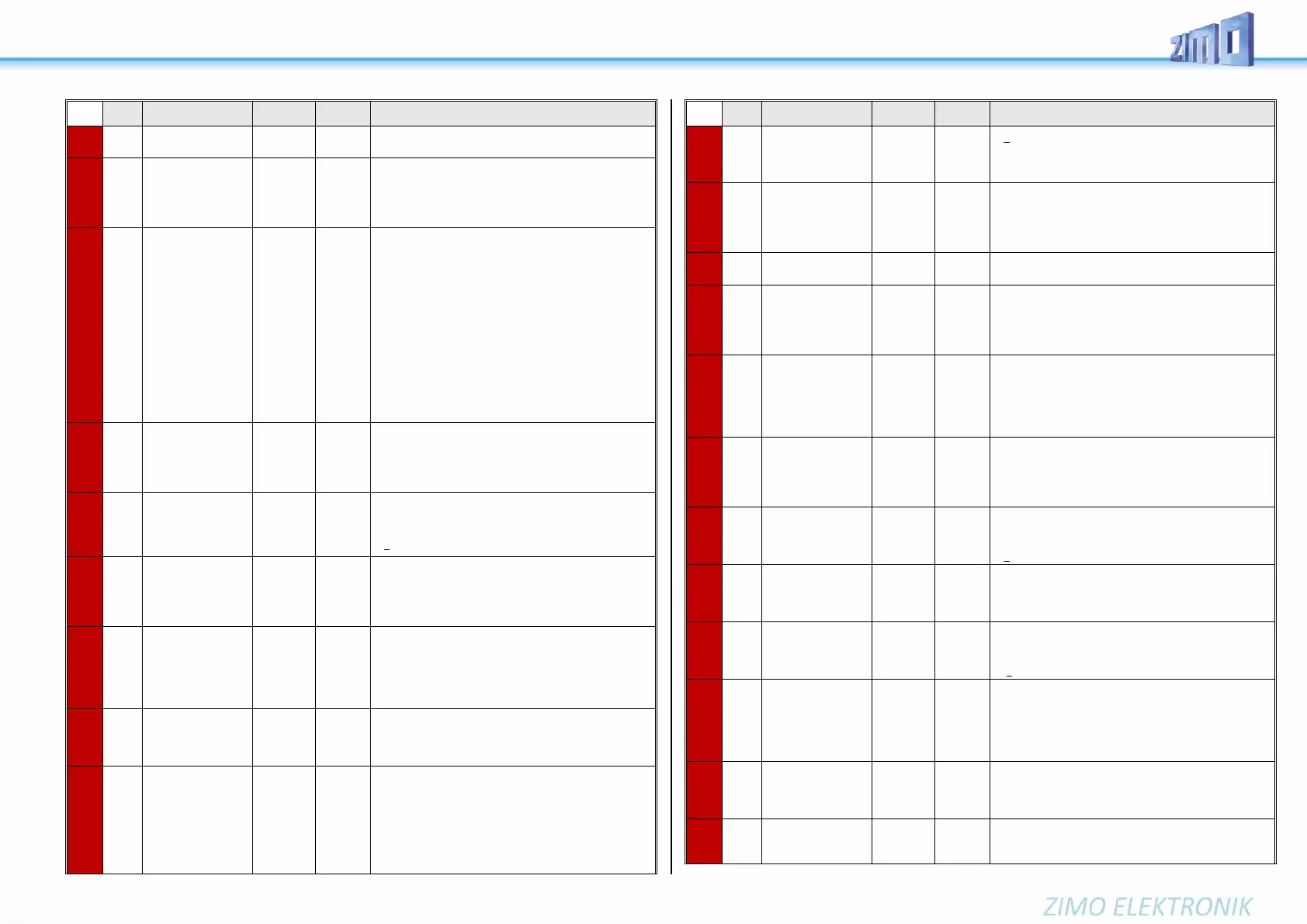

MS - SOUND decoders MS440 to MS990 and MN - NON-SOUND decoders MN170 to MN340 Page 75

Bit 6 = 1: Transition sets in diesel projects, which are

played back when switching from one set to another.

Key

to switch key for

driving and sound

performance when

driving solo

0=: no key, no solo drive

= 1 - 28: One function key (F1 – F28) acts as the switch-

over key for driving a heavy train or a single locomotive.

If the

key for solo drive

(CV #347, see

above) is activated,

the measures de-

fined here have to

be met.

Bit 2 already in version

4.10

Bits 0, 3, 4 (only Diesel):

When driving solo (function key as per CV #347 is ON):

Bit 0 = 1: ... Diesel sound (sound steps) should

rev up unlimited to maximum rpm (or limited in rela-

tion to speed step as per CV #389).

Bit 1 = 1: acceleration and deceleration times should be

reduced according to CV #3 / #4, but consider

the reduction according to CV #390.

Bit 2 = 1: motor’s idle sound should be played back when

driving at low speeds, whereas the highest speed

step shall still be playing the idle sound set in

CV #391.

Bit 3 = 1: deactivate 2nd smoke fan and heating element

with this key (diesel loco with two engines only

drives with one).

Bit 4 = 1: Suppress brake squeal

Braking time for

brake key

To achieve the desired effect, the deceleration time in CV

#4 must be set to a very high value (@ 50 - 250) but the

brake time in CV #349 rather low (5 - 20). This simulates

a coasting effect with the “regulator at 0”, while the brake

key results in a short stopping distance.

Electric switch gear

sound,

locked after

starting

Time in tenth of seconds (0-25 sec), the switchgear sound

shall not be played back after starting; this is useful if the

first switching step is already in the sample “Stand -> F1”.

= 0: Switchgear is played back immediately after starting.

Speed of the

smoke fan at

constant speed

for DIESEL

locomotives

The speed of the fan is set by PWM; the value of CV #351

defines the behaviour during normal driving.

= 128: Half voltage (PWM) when driving.

Speed of the

smoke fan during

acceleration and

engine starting

for DIESEL

locomotives

To create a cloud of smoke when starting the machines,

the fan is set to higher (usually maximum) speed, as well

as in case of strong acceleration during operation.

= 255: Maximum voltage at start-up

Automatic

turn-off of the

smoke generator

For effects “010010xx” or “010100xx” (smoke generator):

overheating protection: Turn-off half a minute to 2 hours.

= 0: no automated shut-down

= 1 to 255: automatic turn-off after 25sec/unit

Chuff beat

frequency

at

speed step 1

also see

CV #267

in this table

CV #354 works only if used together with CV #267!

CV #354 compensates for the non-linear speed measure-

ments of the “virtual cam sensor”:

While the adjustment of CV #267 is done in the vicinity of

speed step 10 (slow but not very slow), a correction for

speed step 1 can be performed with CV #354 (extremely

slow).

= 0: no effect

= 1 - 127: Steam chuffs at speed step = 1 (and

extremely slow speed) more common than CV #267

= 255 - 128: less chuff beats.

Speed of the smoke

fan at standstill for

STEAM locomotives,

and

DIESEL locomotives

With CV #355 the speed of the fan at standstill - if sound

is switched on - is set. This has the effect of emitting

smoke (a small amount, but visible) even when stopped.

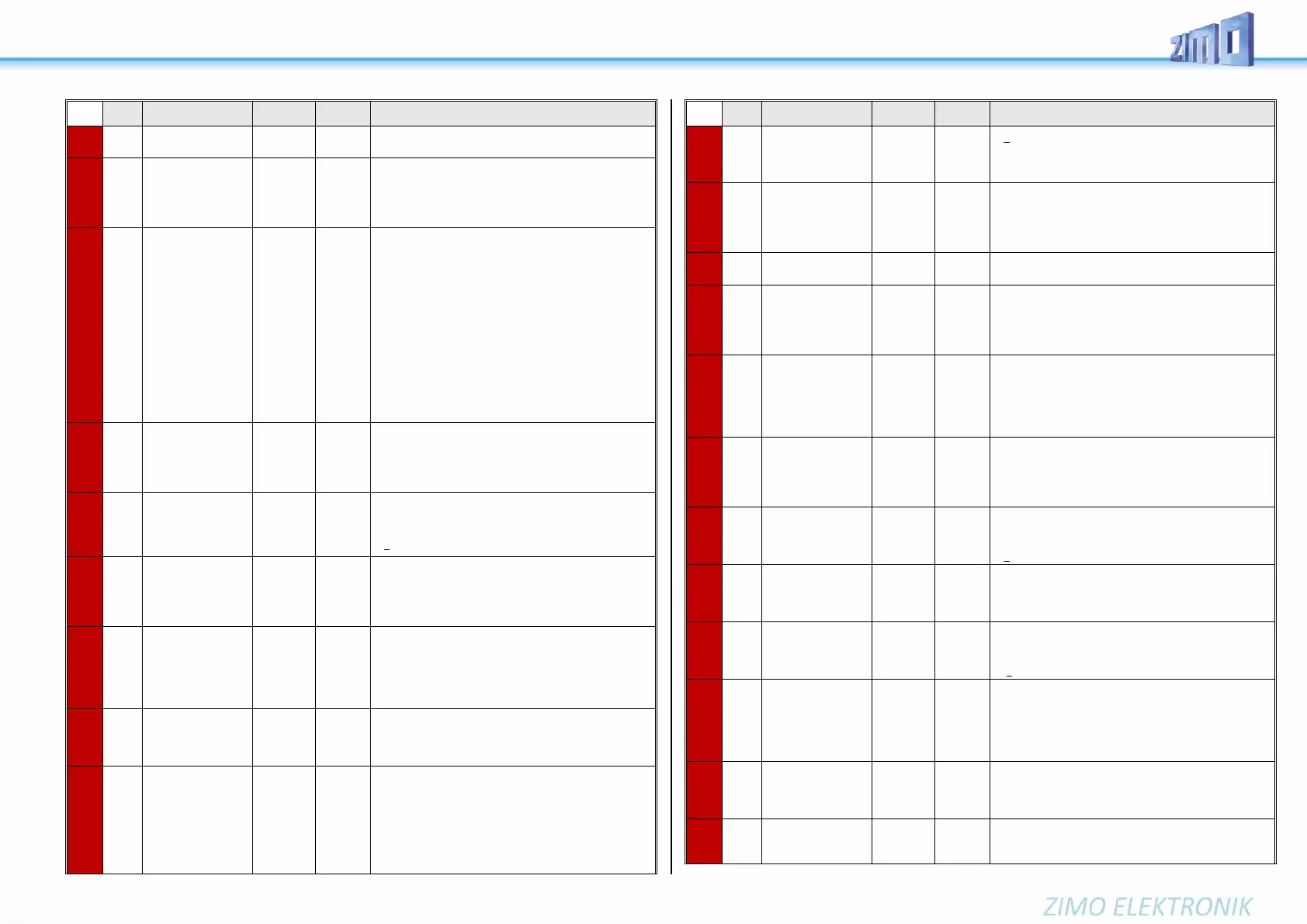

If this key is activated, the speed controller changes the

driving sound, not the speed

Thyristor sound

pitch:

Lowering

volume at

higher speed

Internal speed step at which the thyristor sound volume

should be reduced. The volume stays at this reduced level

while braking.

By changing CV #158 Bit 6 = 1, the volume will be raised

while braking, nonetheless.

Thyristor sound

pitch:

Course of

Lowering

volume at

higher speed

Defines a curve as to how the thyristor sound should be

lowered at the speed step defined in CV #357.

= 0: no reduction.

= 10: reduced by about 3 % per speed step.

= 255: aborts the sound when the speed step defined in

CV #357 is reached.

Electric switch gear

sound,

Switch gear play-

back duration during

speed changes

Time in tenth of a second the switch gear should be heard

during speed changes (adjustable from 0 – 25 sec.).

Effective only if switch gear sound is part of the sound pro-

ject.

Electric switch gear

sound,

Duration of playback

after stopping

Time in tenth of a second the switch gear should be heard

after the engine comes to a full stop (adjustable from 0 –

25 sec.).

= 0: no sound after stop.

Electric switchgear

Time until the next

playback

During rapid successions in speed changes the switch

gear sound would be played back too often.

CV #361: Time in tenths of a second (0 – 25 sec.) de-

fines minimum delay between multiple playbacks.

Thyristor sound

pitch:

Switching threshold

to second sound:

Defines a speed step at which a second thyristor sound for

higher speeds is played back; this was introduced for the

sound project “ICN” (Roco OEM sound)

= 0: no second thyristor sound.

Electric switch gear

sound,

Distribution of speed

steps on switching

steps

Number of shift steps to cover the whole speed range; i.e.

if 10 shift steps are programmed, the switch gear sound is

played back at internal speed step 25, 50, 75… (a total of

10 times)

= 0: synonymous with 5; i.e. 5 switch steps over

the whole speed range.

Diesel engine with

Switchgear

Speed drop during

upshifts

This special CV applies only to diesel-mechanical engines

and defines the typical drop in speed when shifting up. See

sound projects (i.e. VT 61)

Diesel engine with

Switchgear

Upshift rpm

This special CV applies only to diesel-mechanical engines

and defines the highest rpm before shifting up.

See sound projects (i.e. VT 61)

Loading...

Loading...