5

© Copyright 2017 Zoeller

®

Co. All rights reserved.

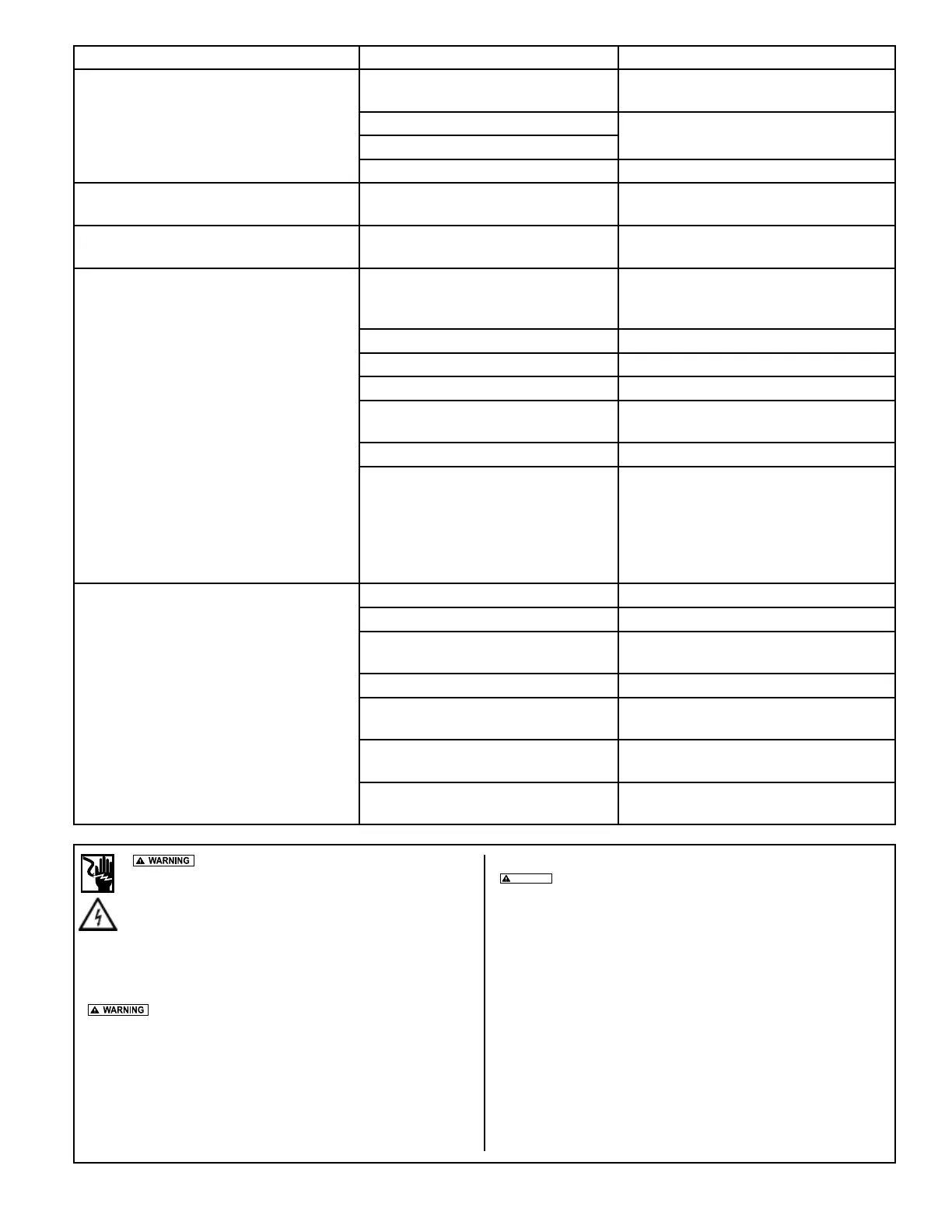

Condition Possible Cause Remedy

PUMP WILL NOT START OR RUN.

Low voltage, blown fuse, open

circuit

Have a qualied electrician check fuse

and circuit.

Impeller bound

Contact a Zoeller Service Center.

Motor or wiring shorted

Debris on oat switch Remove debris

PUMP STARTS TOO SOON. Float “ON” point is adjusted too low

Raise the oat stops, make sure the

oat is between the two stops.

WATER LEVEL EXCESSIVE BEFORE

PUMP TURNS ON.

Float “ON” point adjusted to high Lower the upper oat stop.

PUMP WILL NOT SHUT OFF OR

RUNS TOO LONG BEFORE WATER

IS PUMPED.

Pump not plugged into piggyback

oat switch receptacle

Ensure pump is not plugged directly

into the outlet. Plug pump into

piggyback oat switch receptacle.

Debris under oat Remove debris from around oat.

Faulty oat switch Contact a Zoeller Service Center.

Float “OFF” point adjusted too low Raise the lower oat stop.

Pump is air locked

Make sure vent hole in discharge

pipe is clear.

Water level too low Raise the lower oat stop.

Waste material has accumulated

blocking ow of material

Hold ush handle down on toilet

for 15 seconds. If unit will not clear,

unplug and wait 30 minutes. Plug

unit back in and repeat. If unit still

will not turn off, it will need to be

opened and the debris relocated.

PUMP OPERATES BUT DELIVERS

LITTLE OR NO WATER.

Debris around intake Clean area around intake.

Blockage in discharge pipe Remove pipe and ush out debris.

Low or incorrect voltage

Have a qualied electrician check

house wiring.

Damaged Impeller Contact a Zoeller Service Center.

Incorrect oat adjustment

Contact Product Support

Department.

Pump is air locked

Make sure vent hole in discharge

pipe is clear.

Vertical lift too high

Change discharge piping or contact

Product Support Department.

Before servicing a pump, always shut

off the main power breaker and then unplug the

pump - making sure you are not standing in water

and are wearing insulated protective sole shoes.

Under ooded conditions, contact your local electric

company or a qualied licensed electrician for disconnecting

electrical service prior to pump removal.

Submersible pumps contain oil which become

pressured and hot under operating conditions. Allow 2-1/2

hours after disconnecting before attempting service.

If the above checklist does not solve the problem, consult

Zoeller Product Support Department 1 (800) 928-7867 or

1(502) 778-2731- Do not attempt to service or otherwise

disassemble pump.

Do not dispose of feminine sanitary products,

disposable diapers, dish rags, etc. in the QWIK JON

®

ULTIMA

. They may jam the pump or other plumbing lines

and cause malfunction.

CARE OF FINISH: Soap and water is all that is recommended

for cleaning the outside of the tank. Other cleaning products

may cause discoloration and scratching.

Loading...

Loading...