77 / 184

Valve clearance adjustment

1. Maintenance information

1.1 General information

a. This chapter introduces the operation method of

valve clearance adjustment.

b. The adjustment of the valve clearance can only be

carried out after the engine is removed from the vehicle.

c. Adjust the valve clearance when the engine is at

room temperature (≤35℃).

1.2 Assemble torque value

No. Name Torque

N·m

1

M6×30Hexagon flange bolts

(environmentally friendly color

zinc)

10±2N.m

2

M5×15-5#Hexagon socket

head bolt (oxidized black)

5±1N.m

3

M30×1.5Aluminum screw plug

(dark gray)

16±2N.m

4

M14×1.5Screw plug

(environmental color zinc)

10±2N.m

1.3 Tools, measuring tools, accessories

a. 8# and 14# T-shaped socket wrenches, 5# and 10#

hexagon wrenches, magnet sticks, tweezers, rags;

b. Feeler gauge;

c. Thread fastening glue and sealing silica gel.

2. Operation steps

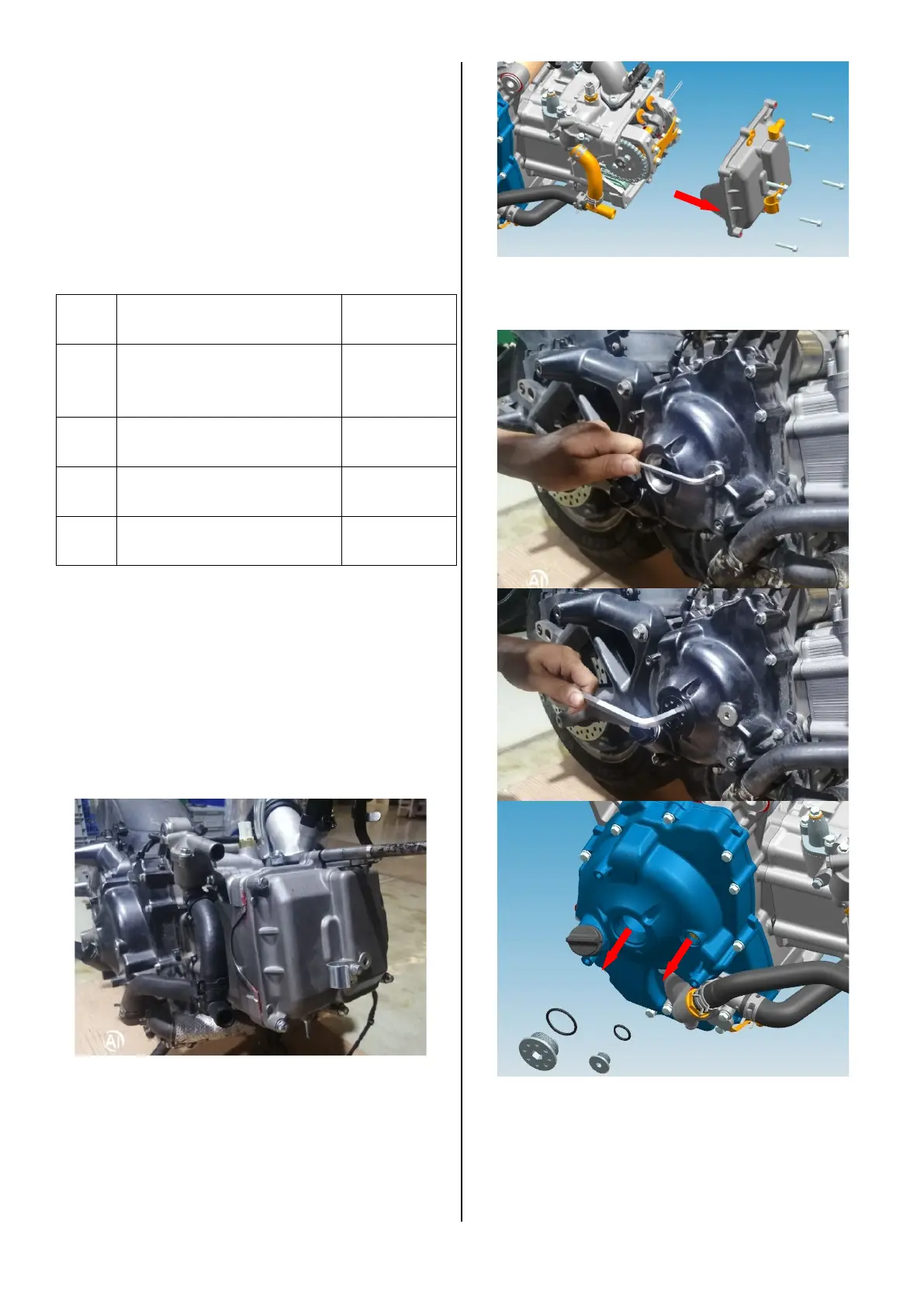

a. Use an 8# T-shaped socket wrench (or a wind

batch) to remove the 6 M6×30 hexagonal flange bolts of

the cylinder head cover, and then remove the cylinder

head cover assembly.

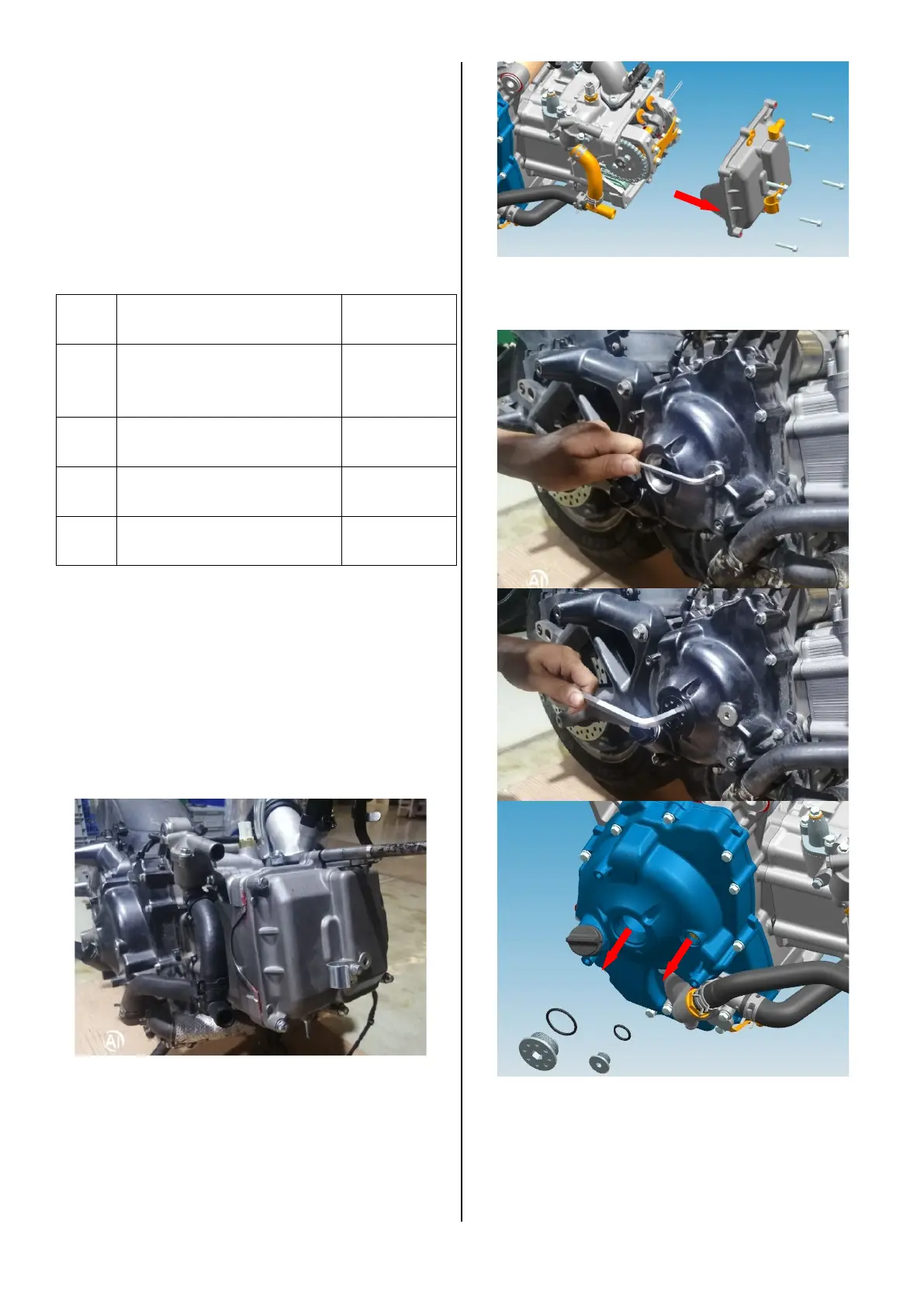

b. Use 5# and 10# Allen wrenches to remove

M14×1.5 screw plugs and M30×1.5 aluminum screw

plugs, and remove the O-ring.

c. Insert the 14#T-shaped socket wrench from the

M30×1.5 aluminum screw plug hole and set it on the

hexagonal head of the flywheel bolt, and then turn the

crankshaft clockwise to align the T-point engraved line

on the flywheel with the mark of the M14×1.5 screw plug

hole gap. At the same time, the top dead center

Loading...

Loading...