ZURN PEX® RESIDENTIAL FIRE PROTECTION SYSTEMS

INSTALLATION INSTRUCTIONS

5

MAKING THE CONNECTION WITH

THE LARGE CRIMP TOOL

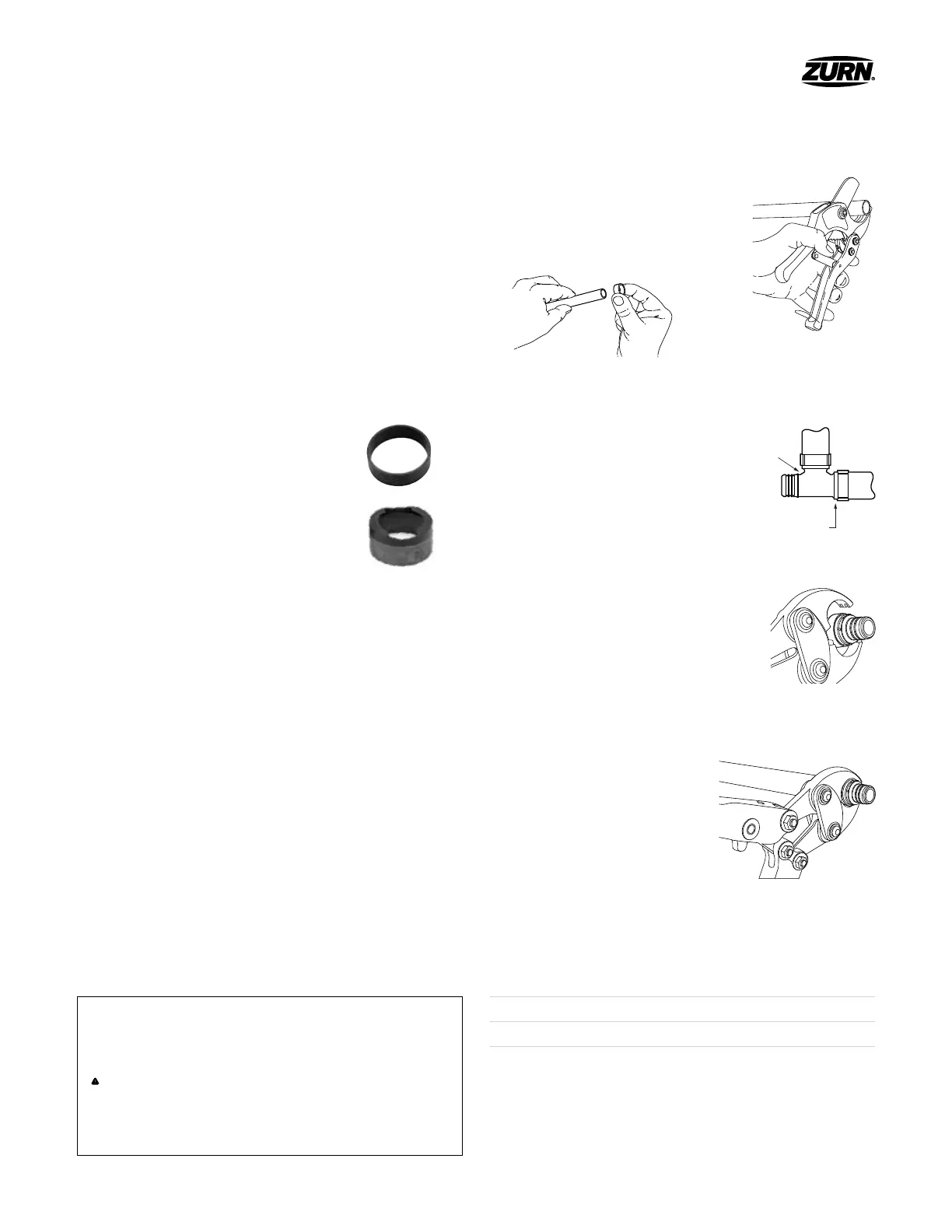

1 Measure and cut the tube. Be sure

you have a square burr-free cut. An

uneven or jagged cut may cause an

improper connection.

2 Next, slip a copper crimp ring onto the tube.

Do not use hose clamps!

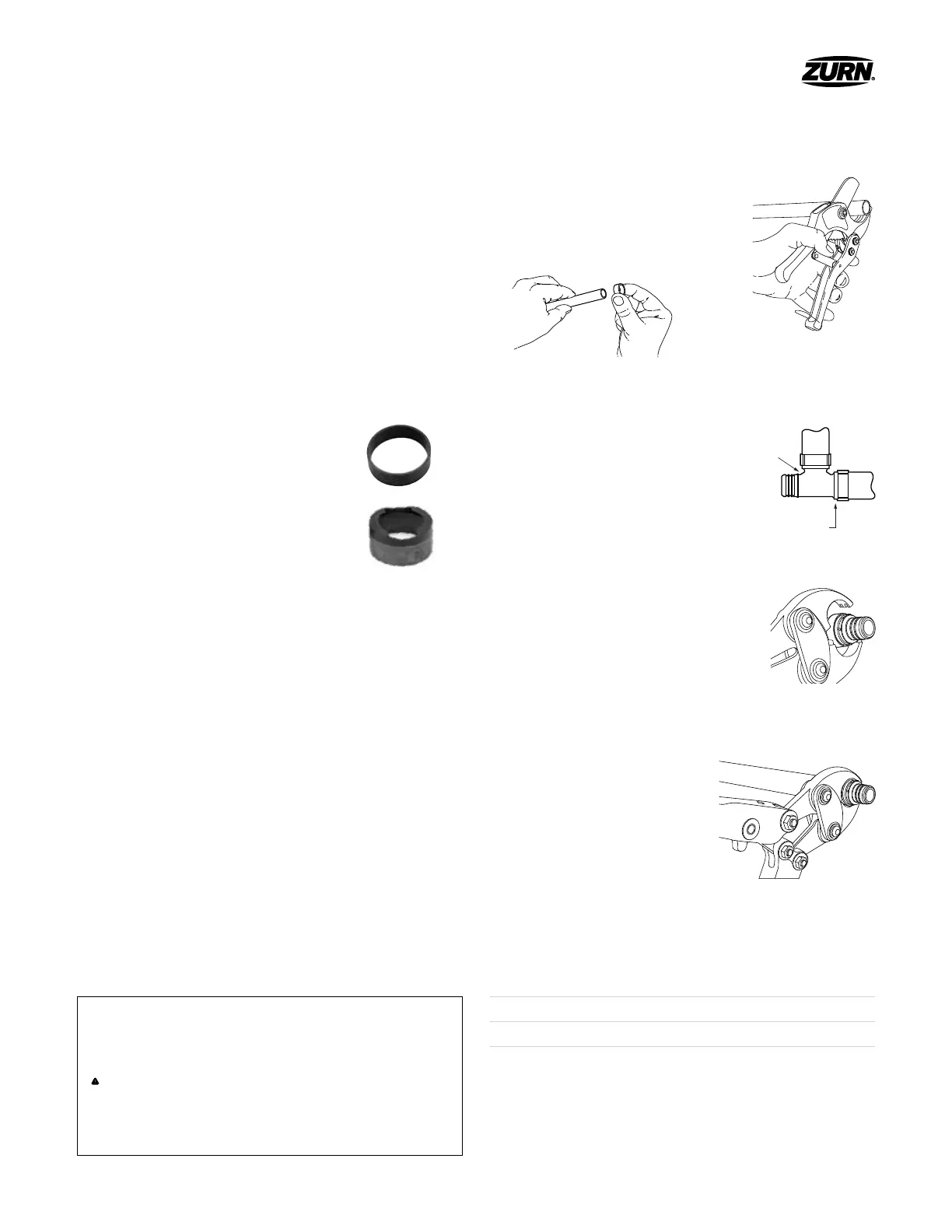

3 Now insert the fitting into the tube

up to the fitting shoulder. Position the

crimp ring 1/8" to 1/4" from the end of

the tube. An improperly positioned ring

may produce a weak connection. Ring

may be squeezed to hold it in place until

step 4 is completed.

4 Position the tool so the crimp ring is

completely covered by the tool jaws.

Keep the tool at a 90° angle to the fitting

and close it completely. Squeeze handles

together to complete the crimp.

5 Open the tool handles to release jaws from the crimped fitting.

6 Measure the crimped ring with

Zurn “Go/No-Go” gauge. See table

below. Do not measure bumps on

ring where jaws met. If “Go” on

gage does not fit, or if “No-Go”

does fit, then cut out connection,

replace fitting and ring, adjust and

calibrate the tool, and recrimp.

The following dimensions are the ASTM maximum and minimum crimped

ring diameters for crosslinked polyethylene (PEX) pipe installations.

NOTE: Using the large crimp tool for anything other than its intended use

will void the warranty. For troubleshooting and repair assistance, do not

return tool directly to wholesaler. Call Zurn Customer Care for assistance at

1-855-ONE-ZURN. See www.zurn.com for warranty information.

WARNING: This product contains a chemical known to the State of

California to cause cancer, birth defects and other reproductive harm

ADVERTENCIA: Este producto contiene una sustancia química que el Estado

de California como causante de cáncer, defectos de nacimiento y otros daños

reproductivos

STANDARD TUBE SIZE > 3/8" 1/2" 3/4" 1"

Minimum Diameter 0.580" 0.700" 0.945" 1.175"

Maximum Diameter 0.595" 0.715" 0.960" 1.190"

Variation in ring diameter (out-of-round) should not exceed 0.006".

1/8¨ to 1/4¨

Crimp Ring

Spacing

Fitting

Shoulder

Fitting

Shoulder

1/8" to 1/4"

Crimp Ring

Spacing

Making Crimp Connections

COLD WEATHER

INSTALLATION CONNECTIONS

Crimps are intended to be made in general working temperatures

above 32°F. However, in extreme temperatures down to 0°F, we

recommend more frequent gauging to ensure in specification

crimps are being made.

Zurn PEX oers the following crimp systems for the installation

of multipurpose fire protection systems: Copper crimp ring and

QickCap® copper crimp ring with positioning end cap. To choose

the crimp system most appropriate for your installation, consider

factors relative to your jobsite priorities.

COPPER CRIMP RING SYSTEM

• Proven system for over 30 years

• Copper Crimp Ring, QCR_X,

available in 3/8"-2"

• QickCap Copper Crimp Ring

with Positioning Cap,

• QCR_XPC, is available in 1/2"-2"

• Go/No-Go Gauge

• 25-year system warranty

Listings

By NSF International as meeting the following standards:

• ASTM F877

• ASTM F1807

• CAN/CSA B137.5

• NSF Standard 14

Loading...

Loading...