ZURN PEX® RESIDENTIAL FIRE PROTECTION SYSTEMS

INSTALLATION INSTRUCTIONS

6

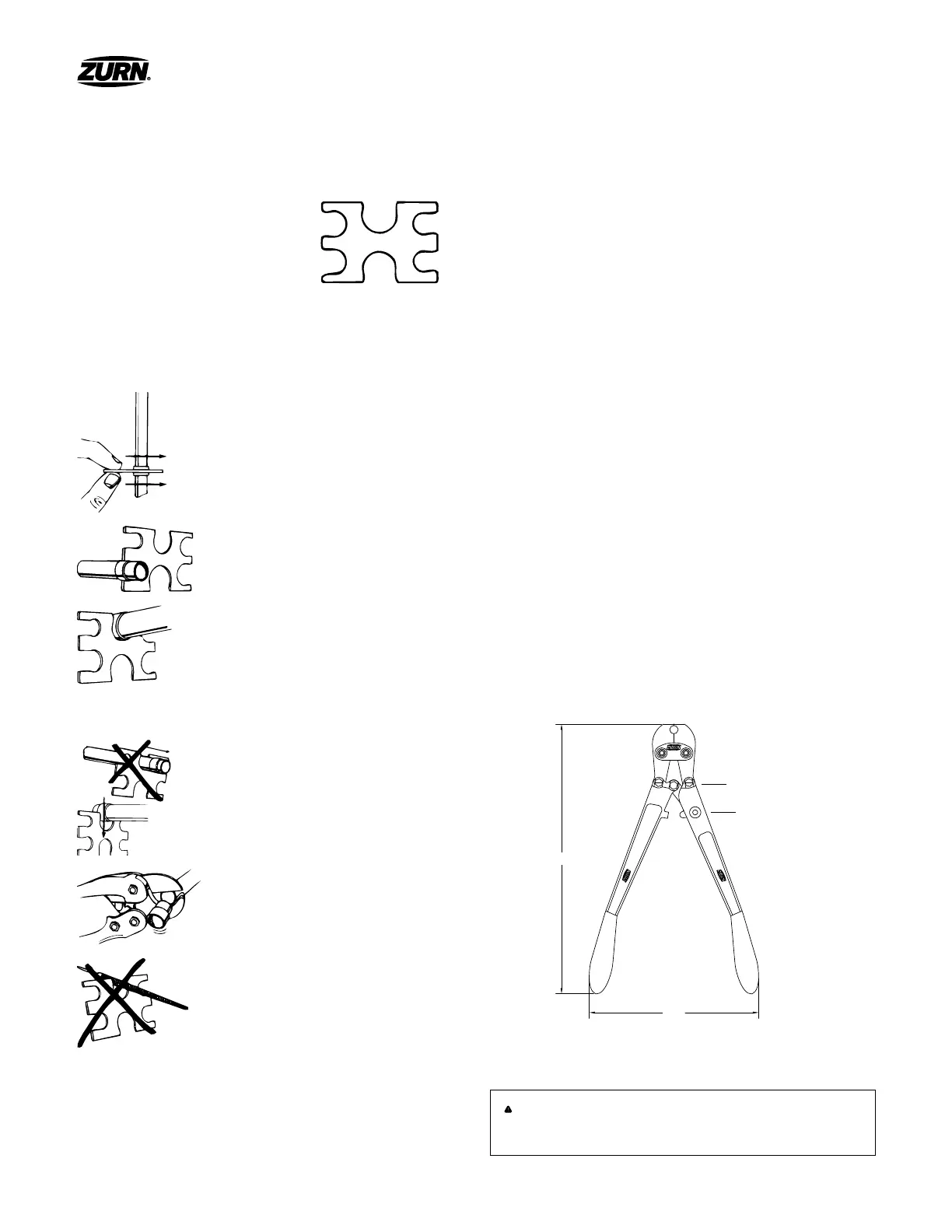

USING THE ZURN GO/NO-GO GAUGE

After making a crimp connection, use

the appropriate opening of this flat

“Go/No-Go” Gauge to check your

finished crimp. The “Go” opening

should go freely across a crimped

ring anywhere on its diameter with

the possible exception of the upset

area on the ring surface caused by

the tool jaws closing. Do not force the gauge across the ring. The

“No-Go” opening should not go across a crimped ring anywhere.

If the crimp fails either test, cut out the fitting and replace.

DO:

Always place the gauge opening on

the crimp ring at a 90° angle for an

accurate check.

Go and No Go Openings

No Go

No

Go

Go

Go

No Go

Go

Be certain to use the gauge opening sized

for the diameter of your tube.

We recommend you check every finished

crimp with this gauge.

DO NOT:

Do not slide the gauge onto the

connection. Push it directly onto the

crimp ring.

Yes

Do not try to save time by recrimping a

crimp that does not gauge properly. The

fitting must be cut out and replaced.

Do not modify the gauge opening for

any reason. They have been carefully

manufactured to .002" tolerance.

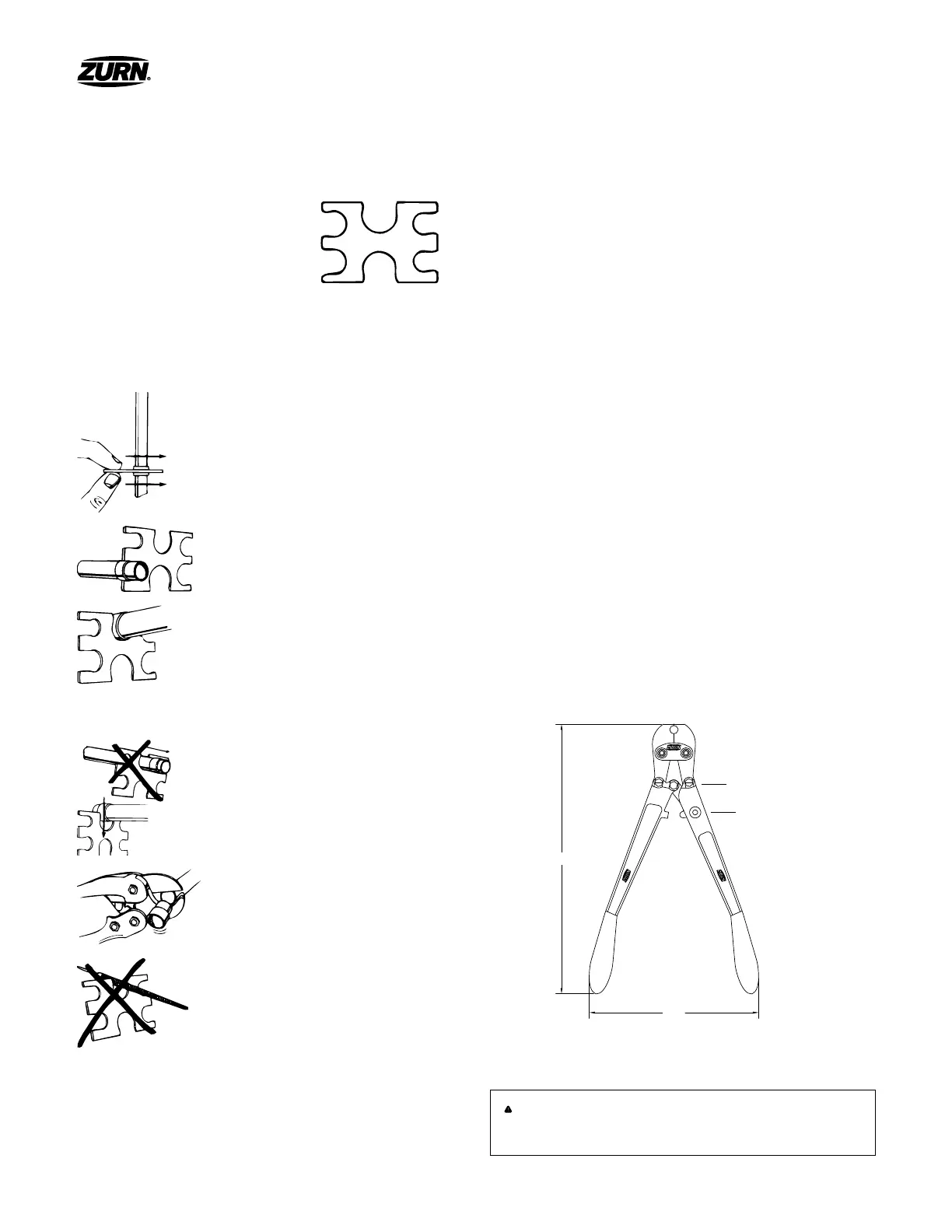

ADJUSTING THE LARGE CRIMP TOOL

Zurn Crimp Tools are factory set to provide proper crimps. This

should be checked before use by making a test crimp connection

and checking it with the crimp gauge. As long as the finished crimp

connection gauges properly, there is no need to adjust the tool.

1 Loosen the bottom Locking Setscrew two turns using the hex

wrench provided with the tool.

2 Close the tool until the jaws just touch and increased resistance

is felt. This is the pre-load point.

3 Turn the top Adjusting Setscrew until the distance between

the raised “+” marks on the handles is between 7" and 8-1/2"

for QCRT2T, 3T, JT, and 4T. The distance for QCRT5T should

be 13". Tighten the bottom Locking Setscrew. See Warning for

QCRT2T, 3T, JT, 4T, and QCRT5T tool.

4 Make a test crimp connection and check it with the “Go”

and “No-Go” openings of the gauge. If the “No-Go” opening

goes over the crimped ring, the tool is too tight. The distance

between the “+” marks should be decreased. If the “Go”

opening does not go over the crimped ring, the tool is too loose

and the distance between the “+” marks should be increased.

5 Apply a light oil to the pivot points each time the tool is

adjusted. Failure to lubricate the tool will shorten its life.

WARNING: Increasing the pre-load distance beyond 9" for the QCRT2T, 3T,

JT, 4T or 13" for the QCRT5T will make the tool hard to use and shorten tool life

because of excessive stress.

QCRT2T, 3T, JT, 4T

'B'

'A'

7"-8-1/2"

Adjusting Screw

Locking Screw

Loading...

Loading...