ZURN PEX® RESIDENTIAL FIRE PROTECTION SYSTEMS

INSTALLATION INSTRUCTIONS

9

IMPORTANT: When running Zurn PEX tubing, be sure to keep it away from potential sources of heat. Maintain a minimum of 12" between Zurn PEX and any recessed

light fixture and a minimum of 6" between Zurn PEX and any gas appliance vent.

The use of zip ties to attach Zurn PEX to DWV piping is acceptable so long as the ties leave enough room for free movement of the tubing.

NOTE: When installing runs of Zurn PEX, it is sometimes necessary to pull one tube past another. Care should be taken to make sure that the friction of the moving tube

does not burn or wear a notch in the stationary tube. If this occurs, the notched section of the tube must be cut out and replaced.

TUBING EXPANSION

Zurn PEX tubing should not be pulled tight during installation.

Adequate slack should be determined in order to prevent

the tubing from exerting tensile loads on the connections

to the fittings.

Allow 1/8" per foot of tube length as slack. This should cover

installations from 35°F to 160°F.

BENDING ZURN PEX TUBING

The minimum bend radius for Zurn PEX is 6 times the outside

diameter of the tubing, when bending it with the natural curvature

of the coil.

Note: If you must bend against the natural curvature of the coil,

these minimums must be multiplied by 3.

METAL STUDS

Protective sleeves or bushings should be used on Zurn PEX tubing

when penetrating metal studs. Sleeves and bushings are not

required when penetrating ordinary wood or particle board if the

holes are at least 1/8" larger than the tube size and tube movement

is not restricted.

INSULATING TUBING

Zurn PEX is resistant to freeze damage; however, installation

specific variables can aect the performance of the system if it

is allowed to freeze up. In general, plumbing codes specify that

tubing run through attics and exterior walls should be insulated.

As such, Zurn PEX tubing should be insulated according to code

requirements. Insulation that is typically used in copper and

CPVC installations would provide equivalent protection for

Zurn PEX tubing.

Note: When using expanding foam to insulate tubing, please

contact Zurn for recommendations. While many expanding foams

have been tested and have shown no adverse eects to PEX

tubing, we cannot guarantee all foams are the same.

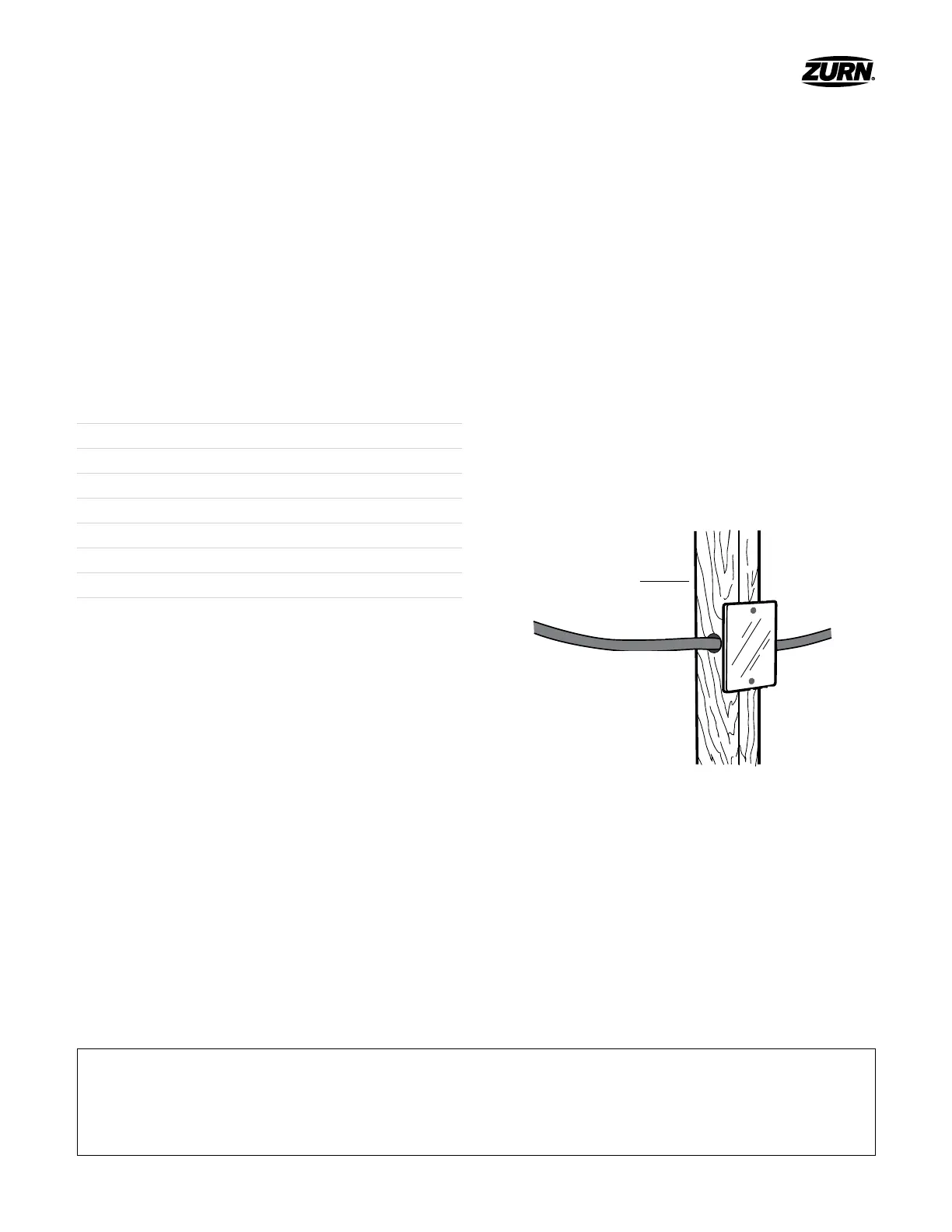

NAILING PLATES

Nailing plates should be used when Zurn PEX tubing is passing

through a stud within 2" of a nailing surface. Using a nailing plate

minimizes the possibility of damage to the tube from nails or

drywall screws.

Note: Best results are achieved by using clamps, pipe insulators,

and strapping designed for plastic plumbing systems.

TUBING SIZE OUTER DIAMETER MINIMUM BEND RADIUS

3/8" .500" 3.00"

1/2" .625" 3.75"

3/4" .875" 5.25"

1" 1.125" 6.75"

1-1/4" 1.375" 8.25"

1-1/2" 1.625" 9.75"

2" 2.125" 12.75"

Wall Stud

Loading...

Loading...